MAINTENANCE MANUAL

STEMME TSA-M

MAINTENANCE MANUAL

STEMME TSA-M

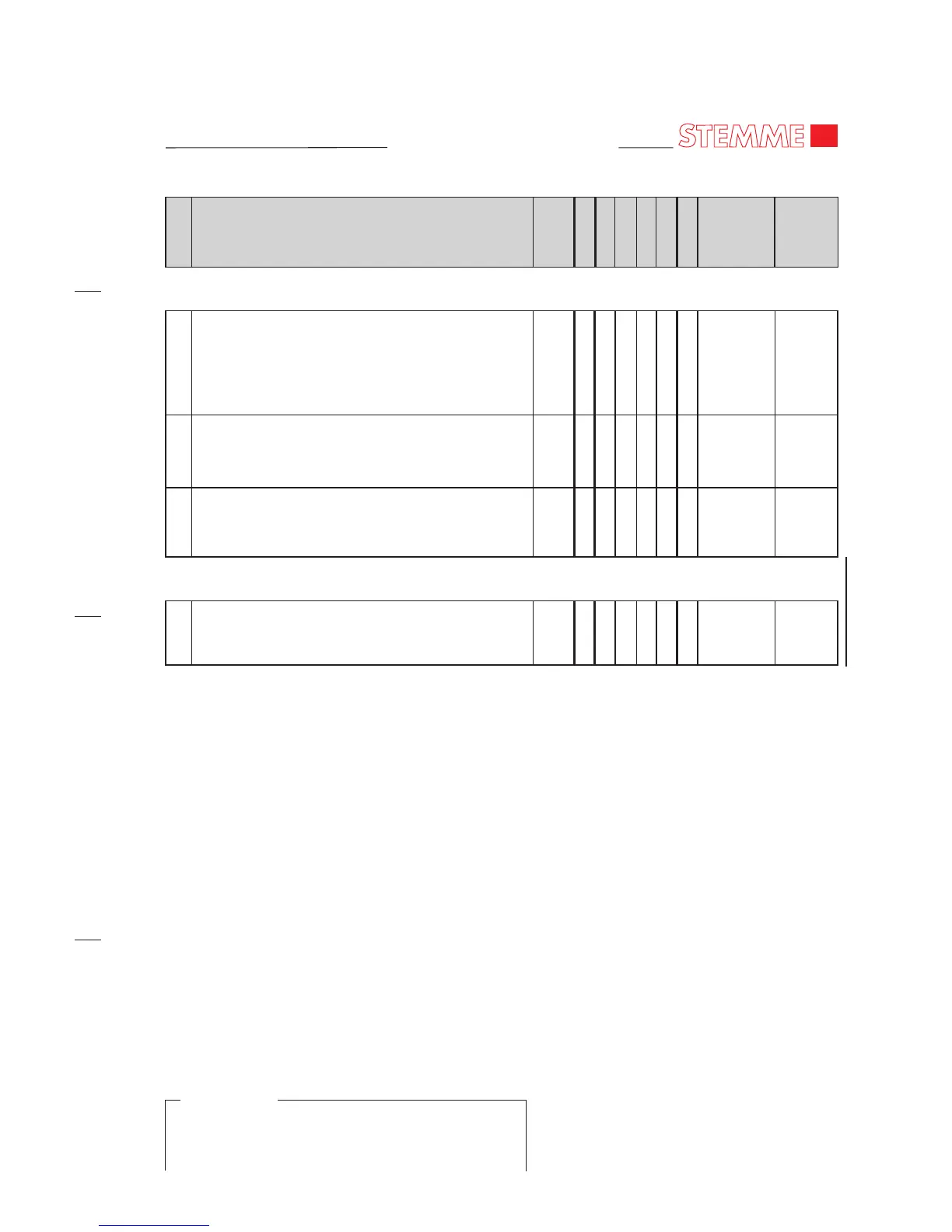

1. Check condition of nose gear tire and check tire

pressure: 3.5 ± 0.2 bar / 51.0 ± 3.0 p.s.i.

2. Visually inspect wheel fork for cracks or

deformations.

3. Check function of wheel fork damping system.

4. Check drag strut condition, locking mechanics,

attachments, hinges and all final postion micro

switches for damage, deformation and dirt.

5. Check hydraulic actuator for damage,

deformation, leakage and dirt.

1. Check nose and main landing gear doors for

condition, correct mounting, actuation, damage

and gas springs.

2. Check doors to be fully closed when landing gear is

retracted with functional check under 5.4.5.

1. Check hydraulic fluid level at dipstick of hydraulic

drive unit (min. lower mark, max. upper mark).

Refill if necessary.

2. Check pressure reservoir for pressure of 90 bar /

1305 psi ± 8% (refer to Flight Manual, chapter 4.5).

If pressure is lower, activate main switch (BATT)

with landing gear switch DOWN. Hydraulic drive

unit has to pump up reservoir up to

90 bar / 1305 psi ± 8% automatically (red check

light has to go out above 90 bar / 1305 psi ± 8%).

3. Check all hydraulic lines and both pressure

reservoir bottles, fittings and hydraulic actuation

unit for condition, damage and leakage.

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

5.4.4 Hydraulic Drive Unit

5.4.3 Landing Gear Doors

Reference Initials

Motor 100h

Motor 25h

Airframe

100h

Motor 200h

Motor 600h

Motor 1000h

Annual

Type and Subject of Inspection

No.

Page 02

05-20-03

Nov 18/11

EFFECTIVITY

Model S6-RT

5.4.2 Nose Landing Gear (Retractable L/G)

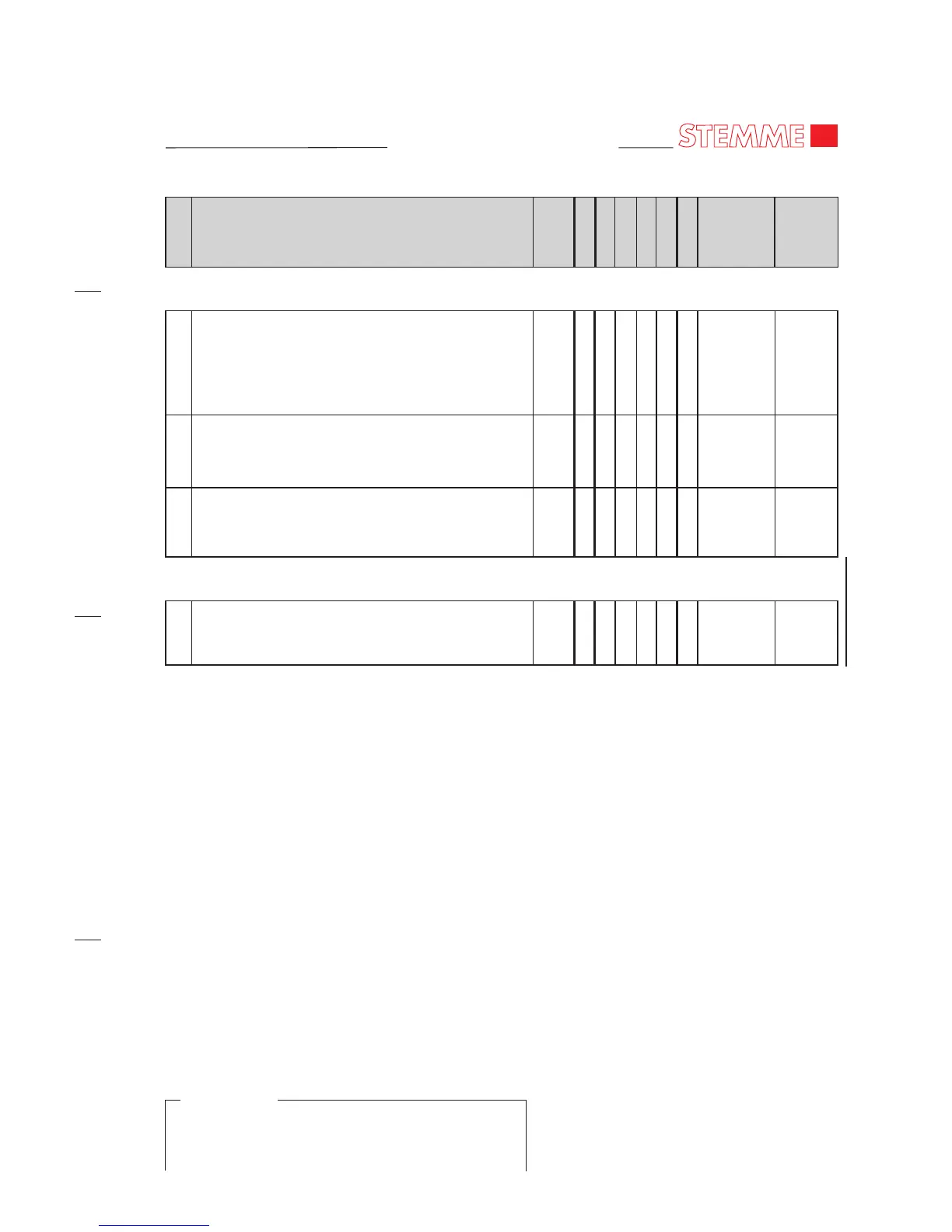

5.4.5 Functional Tests

5.4.6 Engine Cooling System

Page 03

05-20-03

May 04/12

Reference Initials

Motor 100h

Motor 25h

Airframe

100h

Motor 200h

Motor 600h

Motor 1000h

Annual

Type and Subject of Inspection

No.

1. With aircraft fixed on crane perform functional test

of landing gear actuation.

Check free movement of nose and main landing

gear over complete range. Check for collision to

structure of landing gear doors.

2. Check function of landing gear warning by

extending air-brakes with landing gear retracted.

Acoustical warning has to come up.

3. Perform functional test of landing gear emergency

extension. Check hydraulic fluid level afterwards

(ref. 5.4.4).

1. Check function of cooling radiator fan during

engine test run (engine coolant temperature has to

stabilize during warm up).

X

X

X

X

X

X

X

X

X

X

X

X

EFFECTIVITY

Model S6-RT

Loading...

Loading...