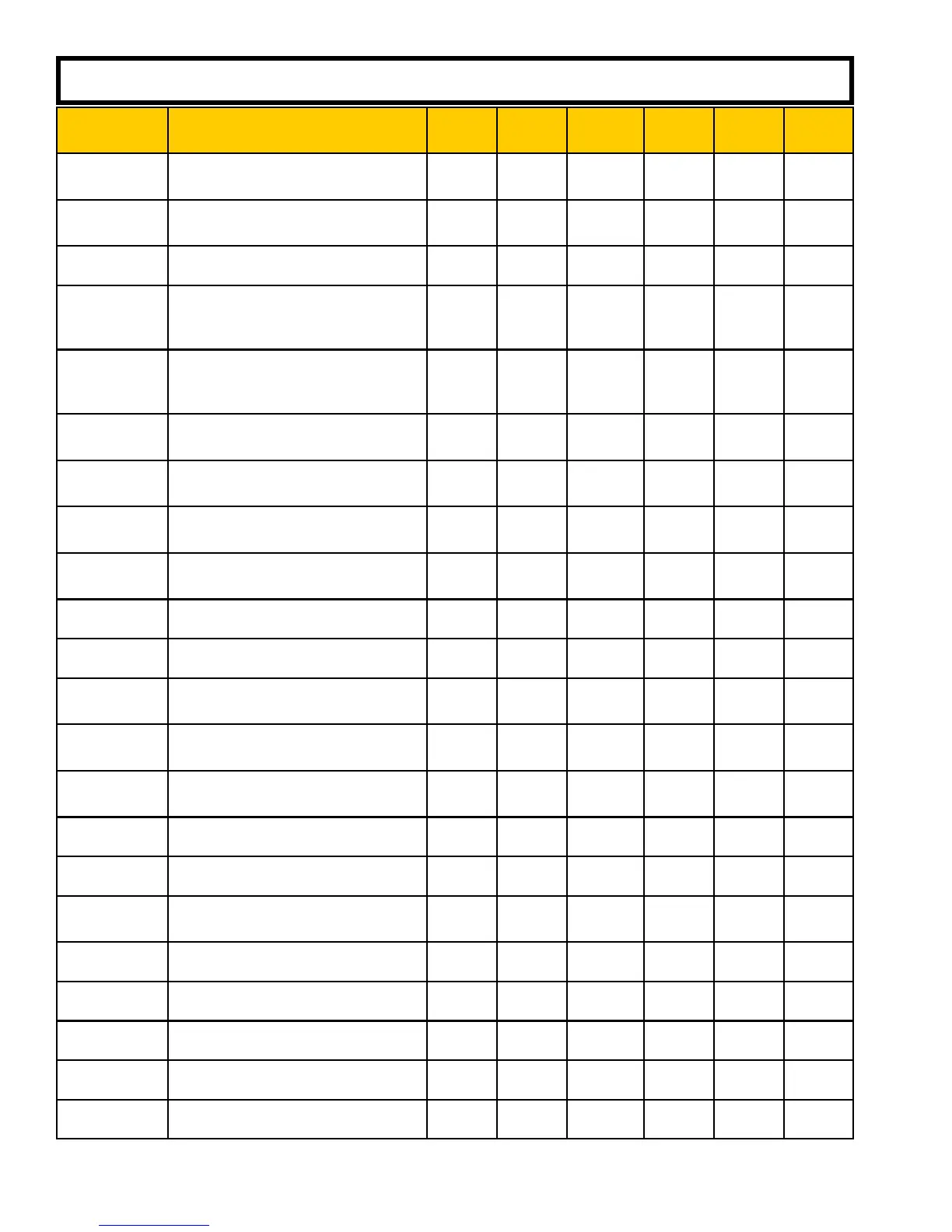

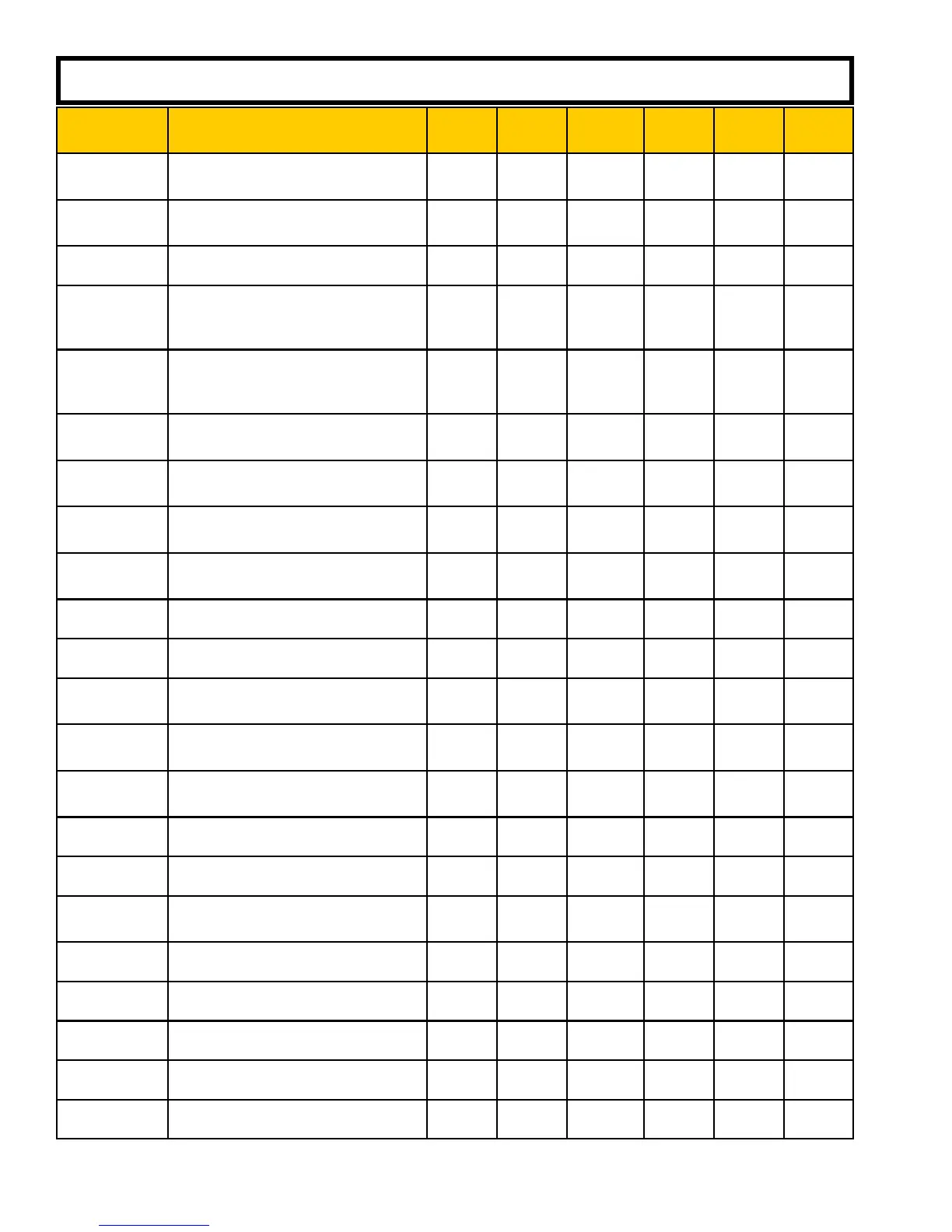

20

ITEM OPERATION TO PERFORM DAILY EVERY

WEEK

EVERY

MONTH

EVERY

3MO

EVERY

6MO

EVERY

YEAR

Product Pump Adjust end clearances and packing as

needed.

Burner Orifice Clean and blow out with compressed

air.

X

Heating Flues Clean and inspect for leaks.

X

Door Hinges

and Slides

Lubricate with high temperature grease.

Inspect for worn or damaged compo-

nents.

X

Hose Assembly

on Spray Wand

Inspect for cracks, fraying, or deteriora-

tion. Replace if needed with original

equipment hose.

X

Hose Assembly

on Spray Wand

Replace with original equipment hose.

X

Main Tank Clean out and inspect for cracks or

other damage. Weld or repair as needed

X

Fuel Filter for

Burner

Install new filter for diesel burner.

Install new strainer for LP burner.

X

Fuel Lines Check for security, damage, and leaks.

Replace with OEM type hose as needed

X

Fuel Tanks Check for damage and leaks.

X

Brakes Test for proper operation.

X

Brake Adjust-

ment/Inspection

Adjust brake shoes to proper clearance.

Check brake shoes for excessive wear.

X

Wheel Bearings Inspect for corrosion and wear. Clean

and repack, install with new seals.

X

Suspension Part Inspect for bending, loose fasteners,

and wear. Repair as needed.

X

Axle Hangers Inspect weld for security.

X

Wheel Nuts Re-torque to proper specs.

X

Tires Check pressure. Inspect for wear, cuts,

or other damage.

X

Hitch Check for damage and loose fasteners.

X

Lights Check for proper operation.

X

SBF MAINTENANCE SCHEDULE

Loading...

Loading...