Do you have a question about the stertil-KONI ST1075-FBF and is the answer not in the manual?

Defines the manual's coverage of operation, installation, and servicing of ST 1075 lifts.

Explains notation styles like Note, Caution, and Warning used throughout the manual.

Provides contact information, address, and website for Stertil B.V.

Emphasizes reading all instructions, working safely, and following behavioral guidelines.

Outlines employer responsibilities for operator training, safety procedures, and documentation.

Details safety measures, emergency stop, and built-in safety features for user protection.

Illustrates and describes various safety and warning labels found on the mobile column lift.

Lists key technical data including lifting capacity, power, and dimensions.

Details the maximum load capacity and design limits of the lift columns.

Explains the electrically driven hydraulic system and column configuration.

Describes how the system ensures synchronized movement and height control of columns.

Details the components that make up the hydraulic power unit.

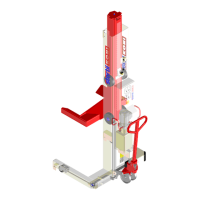

Describes the main structural and functional parts of the column assembly.

Explains the functions of the control panel and its emergency stop switch.

Describes the mechanism used for relocating the column lift.

Explains the mechanical safeguard that prevents the vehicle from falling.

Step-by-step guide for unpacking and setting up each individual column lift.

Instructions on how to connect multiple columns to form a synchronized lifting set.

Principles and guidelines for safe lifting and lowering operations, including elevation differences.

Information on the optional traverse beam for lifting trailers and related precautions.

Procedure for testing the complete lifting system under full load after installation.

Describes the flexibility of operation: all columns, pairs, or single column operation.

Explains the buttons, indicators, and functions of the control box interface.

How to raise the column lifts using the UP button on the control box.

How to lower the column lifts using the UNLOCK and DOWN buttons.

Activates a reduced lowering speed for precise positioning of the vehicle.

How to lower the lift into the safety locks before performing work on the vehicle.

Explains the information displayed on the control box screen, including battery and height status.

How to configure operation modes: Pair Operation, Single Column Operation, and Operating System.

Step-by-step guide to select and operate columns in pairs for axle lifting.

Step-by-step guide to select and operate a single column lift.

Instructions on how to use the pallet lifting mechanism for relocating the column lift.

Essential pre-operation checks and steps before using the column lift.

Steps to prepare the lifts before operation, including fitting adapters and linking columns.

Explains how to use the control buttons for raising, lowering, and mode selection.

Describes manual lowering in emergency situations by authorized personnel.

Outlines daily, monthly, and annual maintenance tasks for the lift.

Details daily checks for damage/leaks and monthly checks for safety features and lubrication.

Details annual inspection tasks performed by authorized service technicians.

Outlines specific procedures for lubrication, hydraulic oil management, and safety checks.

Table detailing monthly, annual, and bi-annual lubrication tasks for lift components.

Instructions on checking and replacing hydraulic oil, including oil type specification.

How to check battery levels and understand warning indicators for low battery status.

Procedure to test the emergency shutdown button's functionality.

Steps to verify the correct operation and clearance of the safety lock mechanism.

Explains the purpose and location of switches used by fitters during maintenance.

Guidelines for battery maintenance, replacement with original parts, and charging.

How to manually lower the lifts when control box operation is impossible due to power failure.

Details how to access and configure various operational settings via the service menu.

How to set a maximum height limit for the lift's operation.

Covers settings like Unlock during Up, Crush Limit, Height Difference Guard, and Height Monitoring.

Settings for odd number of columns, height dimension units, and display language selection.

Settings for motor/system run time, long distance linking, weight dimension, and category.

Configuration for motor type, footguard feature, and information on error messages.

Explains system errors, fault indicators, and messages like 'Down stop limit exceeded'.

Describes the information found on the service sticker behind the control box.

Refers to appendices for electrical diagrams of the control box and hydraulic components.

Guides on diagnosing and resolving system issues and common problems.

Explains how warnings are displayed and provides solutions for common issues.

Details how errors are displayed on the screen and how to reset the system.

Explains fault indications, screen messages, and cancellation procedures for system restarts.

Summarizes common causes and solutions for the lift not raising or lowering, and other issues.

Guides on performing specific maintenance tasks like cylinder removal/installation and mechanism adjustment.

Step-by-step guide for removing and installing the hydraulic lifting cylinder.

How to adjust the pallet lifting mechanism for correct stroke lift.

Guides users to appendices A and B for detailed parts lists and explanations.

Information needed when ordering replacement parts from the manufacturer, including part numbers.

Describes manual lowering capability in power failure situations, requiring trained personnel.

Explains the use and types of wheel adapters for different tire diameters and vehicle compatibility.

Details special longer wheel adapters for specific vehicle types and their restricted lifting capacity.

Information on using the traverse beam for lifting trailers, including pre-work checks and instructions.

Crucial checks on lifting capacities of the beam and columns before use to prevent overload.

Steps for positioning the vehicle, beam, and columns for lifting with the traverse beam.

Use of a specific adapter for trailer suspension and precautions against tilting.

Overview of the main assemblies and numbered components of the column lift.

Detailed breakdown and part numbers for the hydraulic unit.

Schematic diagram of the hydraulic system showing components and flow paths.

Exploded view and parts list for the hydraulic cylinder assembly.

Lists and illustrates the components of the control box.

Shows the electrical wiring and connections for the control box.

Detailed parts breakdown for the pallet jack mechanism.

Information about the connection cables, including pinouts, colors, and assembly.

Illustrates the placement of various safety, instructional, and identification labels on the column lift.

Provides overall dimensions and key measurements of the ST 1075-FBF mobile column lift.

Details parts for various wheel adapters and column extensions.

Lists parts related to the traverse beam option, including adapters and wheels.

| Brand | stertil-KONI |

|---|---|

| Model | ST1075-FBF |

| Category | Lifting Systems |

| Language | English |