OPERATION

Menu structure

www.stiebel-eltron.com WPF | WPF cool | 17

MIXER DYNAMICS

Mixer runtime

Setting range 60 to 240

You can use this setting to adapt the mixer characteristics. The

setting 60 to 240 means 6 K to 24 K control deviation.

The scan rate is 10 s and the minimum on time for the mixer is

0.5 s. The mixer does not respond in the dead zone of ±1 K from

the set value.

Example for the setting 100 = 10 K

The control deviation (set mixer temperature – actual mixer tem-

perature) is 5K. The mixer opens for 5 s, then pauses for 5 s and

starts again.

The control deviation (set mixer temperature – actual mixer tem-

perature) is 7.5 K. The mixer opens for 7.5 s, then pauses for 2.5

s and starts again.

The smaller the control deviation, the shorter the mixer on time

and the longer the pauses.

A reduction of the MIXER DYNAMIC value with the control devi-

ation unchanged increases the on duration and reduces pauses.

Example for setting 100 and a current control deviation of 5 K.

5 K of 10 K = 50% = on duration

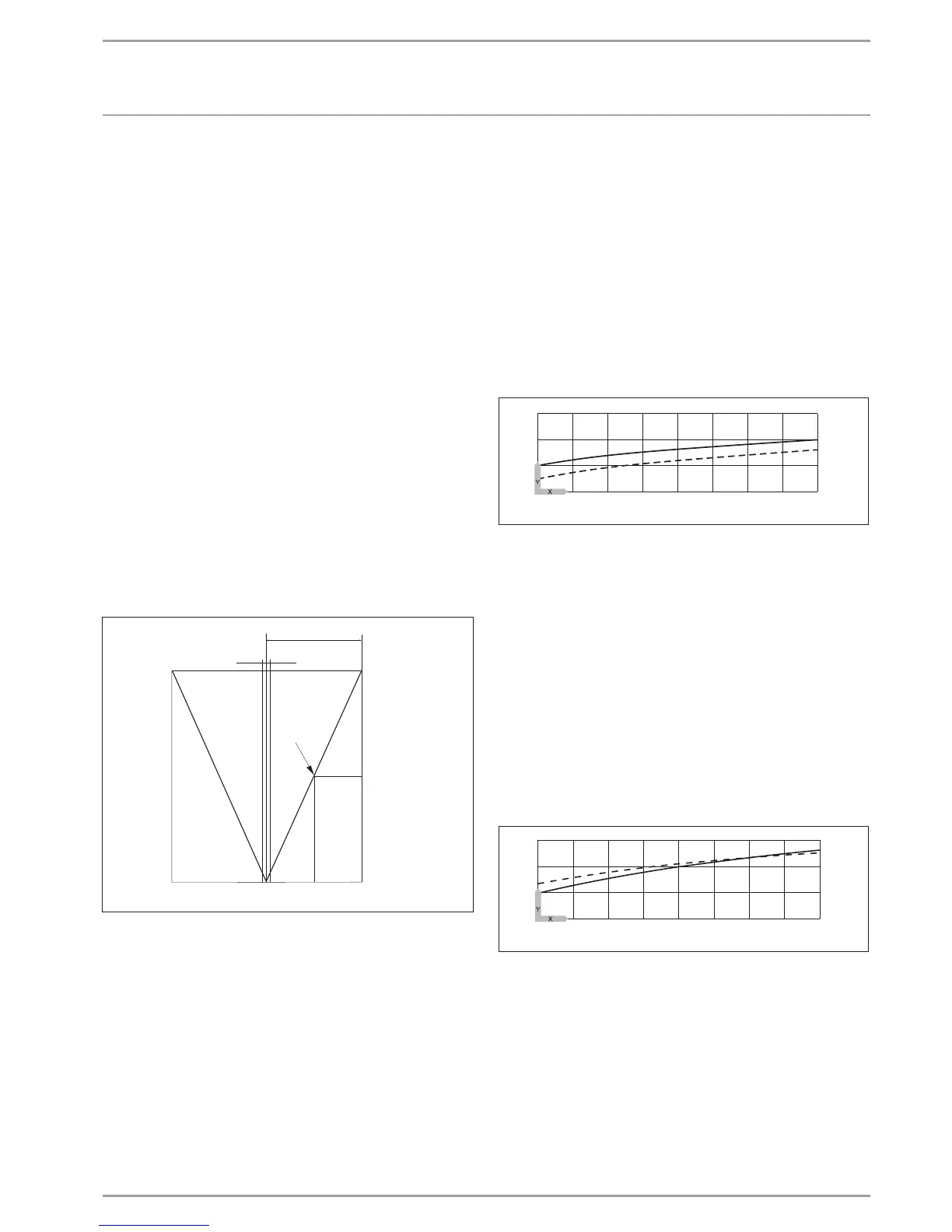

Example: Control deviation

± 1 K

4

3

26�03�01�1067

1

2

1 Setting 100 = control deviation 10 K

2 Control deviation 5 K

3 Control deviation in K

4 On time in %

Heating curve rise

The menu item HEATING CURVE RISE enables you to adjust one

heating curve each for heating circuits1 and 2.

Note: Your contractor will have set a building and system-specific

optimum heating curve for every heating circuit. It relates to the

heat pump return temperature for heating circuit 1 and to the

mixer flow temperature for heating circuit 2.

When adjusting the heating curve on the heat pump manager, the

calculated set return or flow temperature, subject to the outside

temperature and the set room temperature, will be shown at the

top of the display.

As soon as you have preselected a temperature in menu SETTINGS

/ HEATING / STANDARD SETTING under parameter FIXED VALUE

OPERATION, heating curve 1 is hidden from view and the display

showsSETFIXED TEMPERATURE with the relevant temperature.

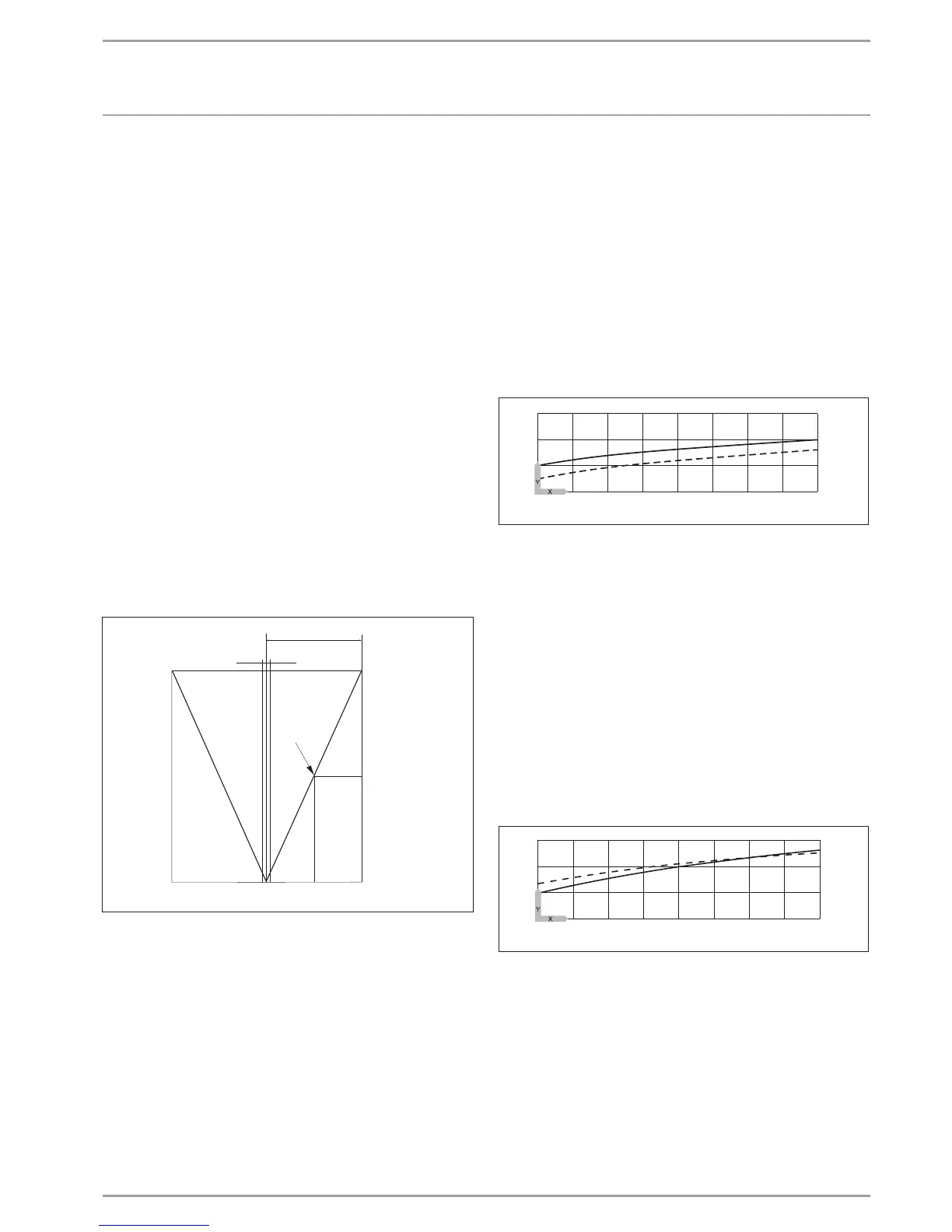

Heating curve

Adjustment of programmed changeover between Comfort and

ECO mode

The figure shows the diagram with the set heating curve relating

to a set room temperature for Comfort mode. The second, dashed

line in the display relates to a set room temperature for ECO mode.

60

40

20

0

1

2

20 15 10 5 0 -5 -10 -15 -20

26�03�01�1915

Y Return/flow temperature [°C]

X Outside temperature [°C]

1 Comfort mode

2 ECO mode

Adapting a heating curve

Example:

During spring and autumn, the temperature of a building's heating

system is too low at an outside temperature between 5 °C and

15°C, despite open radiator valves, but is OK at outside tempera-

tures of ≤ 0°C. This problem can be remedied with a parallel shift

and a simultaneous reduction of the heating curve.

Prior to this adjustment, heating curve 1.0 was adjusted, relative

to a set room temperature of 20 °C. The dotted line indicates the

modified heating curve at 0.83 and a modified set room temper-

ature of 23.2 °C.

60

40

20

0

20 15 10 5 0 -5 -10 -15 -20

26�03�01�1916+

Y Return/flow temperature [°C]

X Outside temperature [°C]

Loading...

Loading...