3..5 Reassembly of Piston

and Cylinder

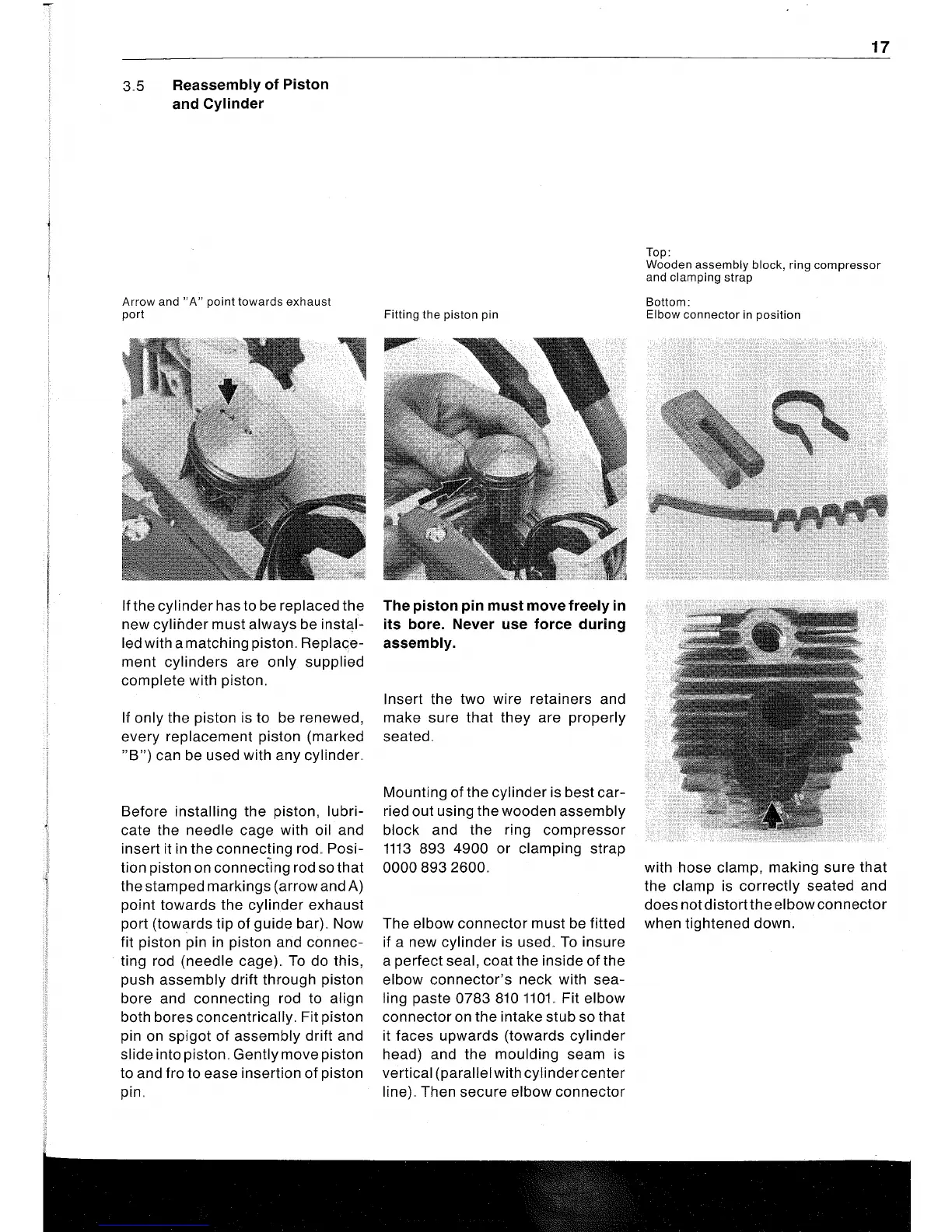

Arrow

and"

A"

point

towards

exhaust

port

If the

cylinder

has to be replaced the

new

cylinder

must always be instal-

led with a matching piston" Replace-

ment cylinders are only supplied

complete with piston"

If only the piston is to be renewed,

every replacement piston (marked

"B")

can be used with any cylinder"

Before installing the piston, lubri-

cate the needle cage with oil and

insert it in the connec!ing

rod"

Posi-

tion piston on connecting rod

sothat

the stamped markings (arrow and A)

point

towards

the cylinder exhaust

port (towards tip of guide bar)" Now

fit piston pin in piston and

connec-

ting rod (needle cage)"

To

do this,

push

assembly

drift

through piston

bore and connecting rod to align

both bores concentrically" Fit piston

pin on spigot of assembly drift and

slide into piston" Gently move piston

to and fro to ease insertion

of

piston

pin,

Fitting

the

piston

pin

The piston pin must move freely in

its bore. Never use force during

assembly.

Insert the two wire retainers and

make sure

that

they

are properly

seated,

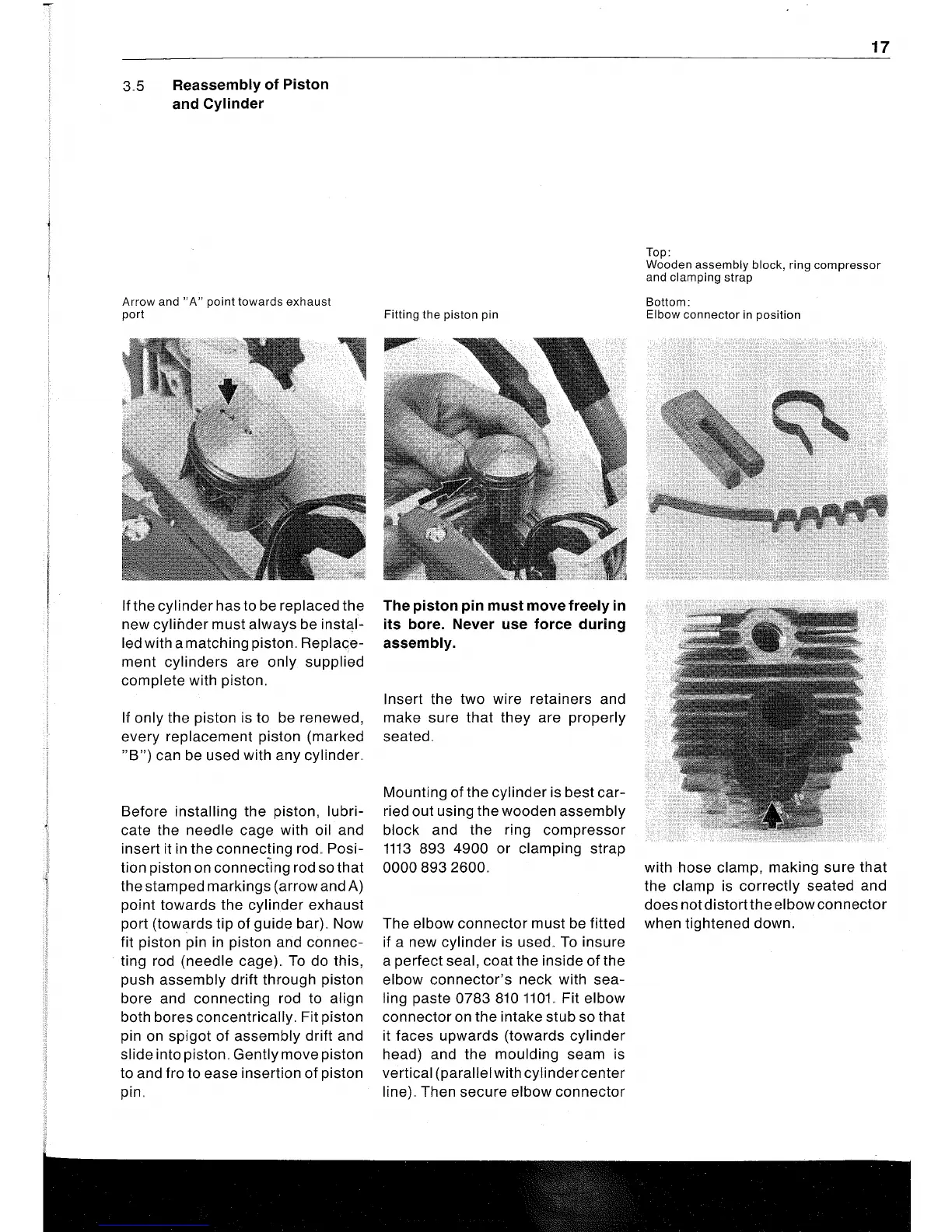

Mounting of the cylinder is best

car-

ried out using the wooden

assembly

block and

the

ring

compressor

1113

893 4900 or clamping strap

00008932600"

The

elbow

connector

must

be fitted

if a new cylinder is used"

To

insure

a perfect seal, coat the inside

of

the

elbow

connector's

neck

with

sea-

ling paste 0783

810

1101"

Fit

elbow

connector

on the intake stub so that

it faces upwards (towards

cylinder

head) and the moulding seam is

vertical (parallel with

cylindercenter

line)" Then secure elbow

connector

17

Top:

Wooden

assembly

block,

ring

compressor

and

clamping

strap

Bottom:

Elbow

connector

in

position

with hose clamp, making

sure

that

the clamp is

correctly

seated and

does not

distortthe

elbow

connector

when tightened down.

Loading...

Loading...