42 Chain and Bar Manual

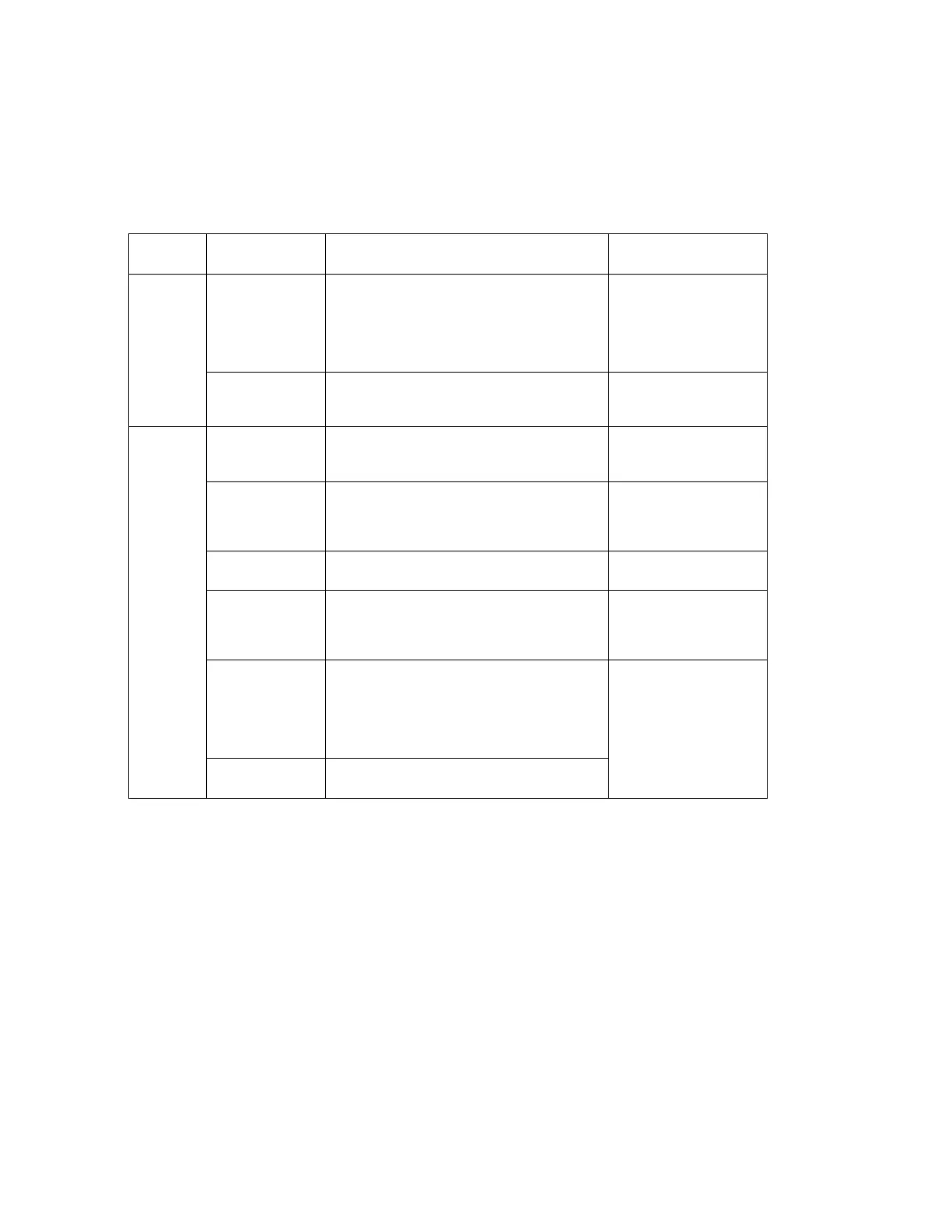

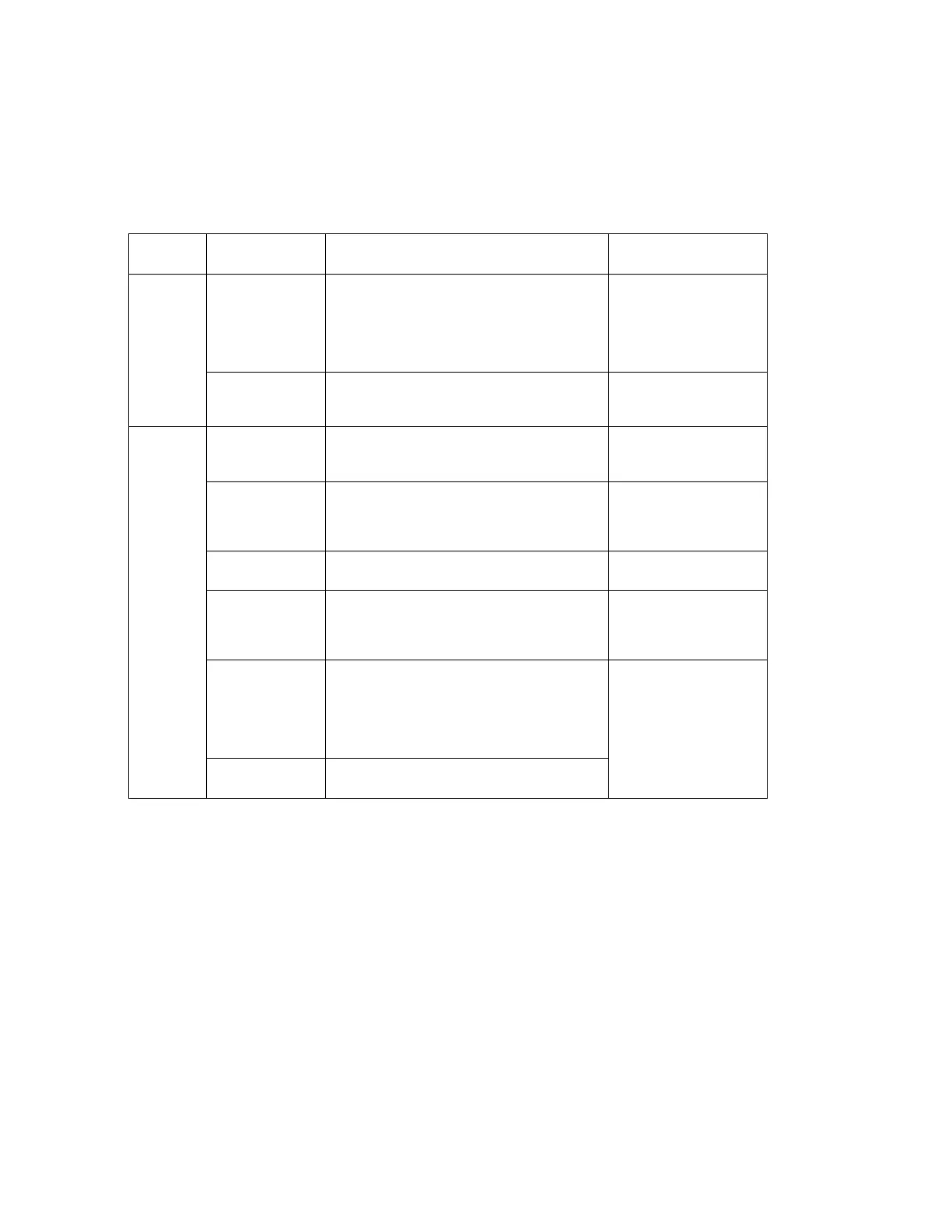

4.3 Guide Bar Applications

Basic

type

Version Description Applications

Duromatic

Duromatic E – made from special tough and wear-resistant

tool steel

– single piece

–laser cut

–resilient (resistant to flexing and warping)

–stellite-tipped bar nose

Heavy-duty

professional

felling and bucking

operations

Duromatic C – special version

–very narrow profile

–very small nose radius

Carving projects, tree

surgery

Rollomatic

Rollomatic E – three welded steel plates

–extremely low weight

–induction hardened rails

All around use,

felling and bucking

operations

Rollomatic E

Light

–three hollowed out, welded steel plates

–cavities filled with fiberglass-reinforced

polyamide

–induction hardened rails

Limbing, tree service

Rollomatic E

Mini

–special version of Rollomatic E

–very narrow profile

All around use on

machines up to 1.5 kW

Rollomatic E

Mini Light

–special version of Rollomatic E Mini

–three hollowed out, welded steel plates

–cavities filled with fiberglass-reinforced

polyamide

Pole pruners,

lightweight saws for

harvesting small-sized

timber

Rollomatic ES – made from special tough and wear-resistant

tool steel

–laser cut

–roller sprocket in separate bar nose

–resilient (resistant to flexing and warping)

–induction hardened rails

Heavy-duty

professional usage in

forestry, agriculture and

construction industry

Rollomatic ES

Light

–special version of Rollomatic ES

–large-area cavities save weight

Loading...

Loading...