Maintenance Model 6DS-SP Planarizer

8 - 4 Version 4.0 - February 1998

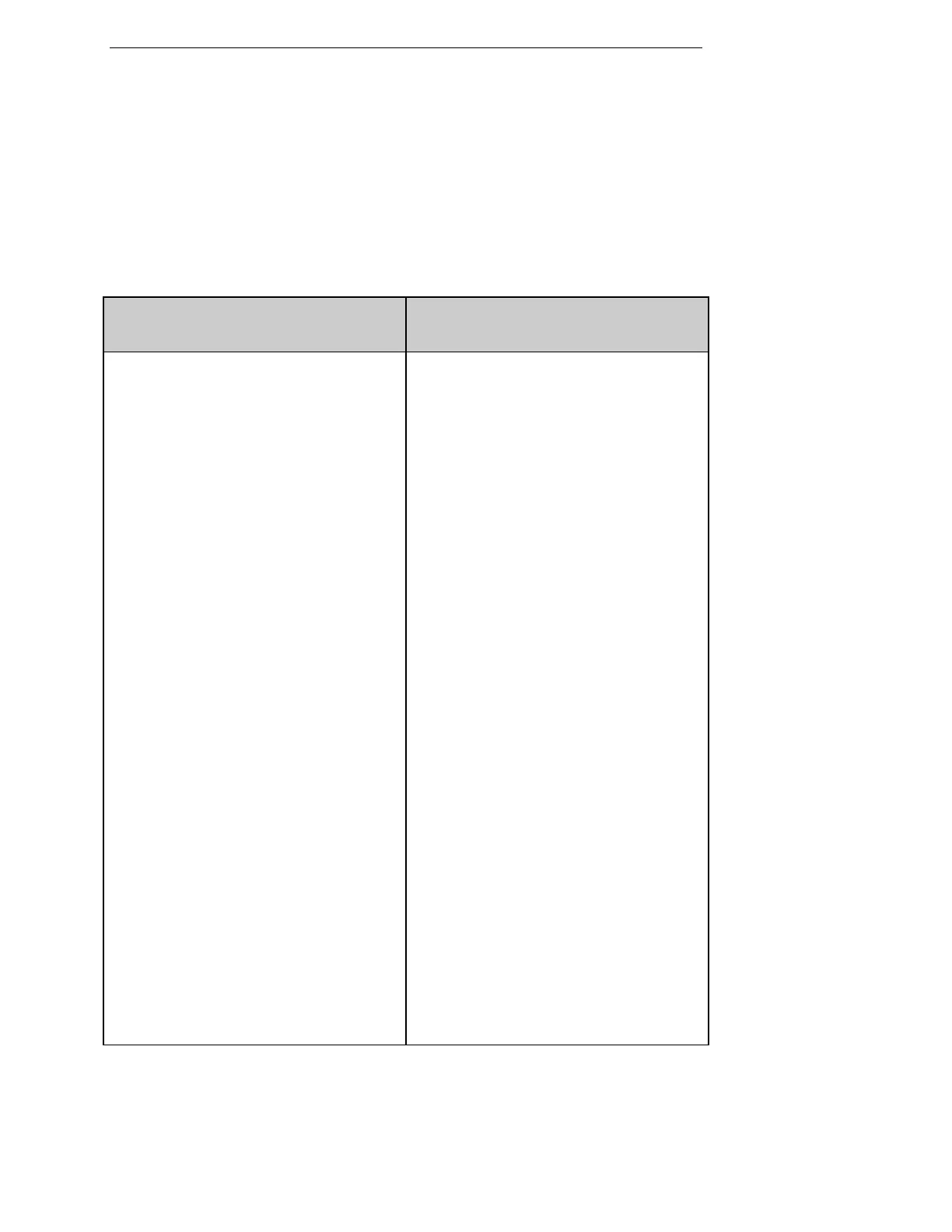

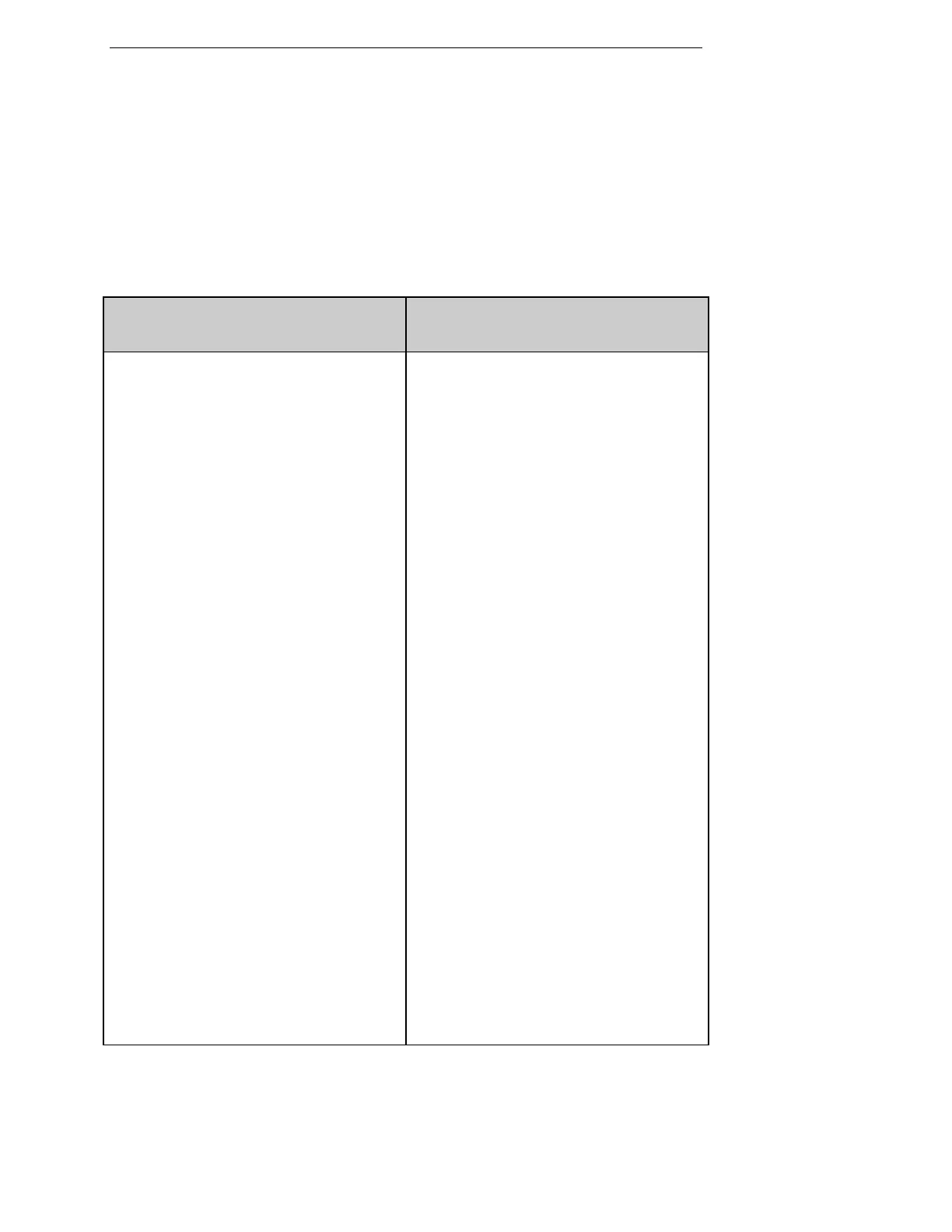

DAILY PREVENTIVE

MAINTENANCE SCHEDULE

SUBJECT ACTION

• Carrier/Wafer Cleaning Stations

• Carriers

• Dial Pressure Gauge Readings

• Elevator Tanks

• Machine Cabinet and Surfaces

• Polish Pad

• Polish Table and Splash Ring

• Robot Vacuum Chuck

Wipe down inside and out, removing

residue.

Clean and inspect wafer template rings

for damage each time the wafer backing

film is changed or each time a wafer

comes out of the carrier on the table

during processing.

Check carrier pocket depth each time

wafer backing film or template ring is

replaced.

Check for proper readings for

compressed air, chuck air blow off, chuck

vacuum, DI water flow, spindle raise

pressure, spindle blow off, and slurry

diaphragm pumps.

Wipe down inside.

Wipe down inside and out, removing

residue.

Inspect and change each shift.

Clean, removing residue.

Clean:

(1) Pull vacuum line off stainless steel

tube and make sure tube is clear.

(2) Lift chuck out of end effector.

(3) Gently scrape off slurry residue.

(4) Wipe clean.

(5) Replace in end effector.

(6) Replace vacuum line.

Loading...

Loading...