Maintenance Model 6DS-SP Planarizer

8 - 6 Version 4.0 - February 1998

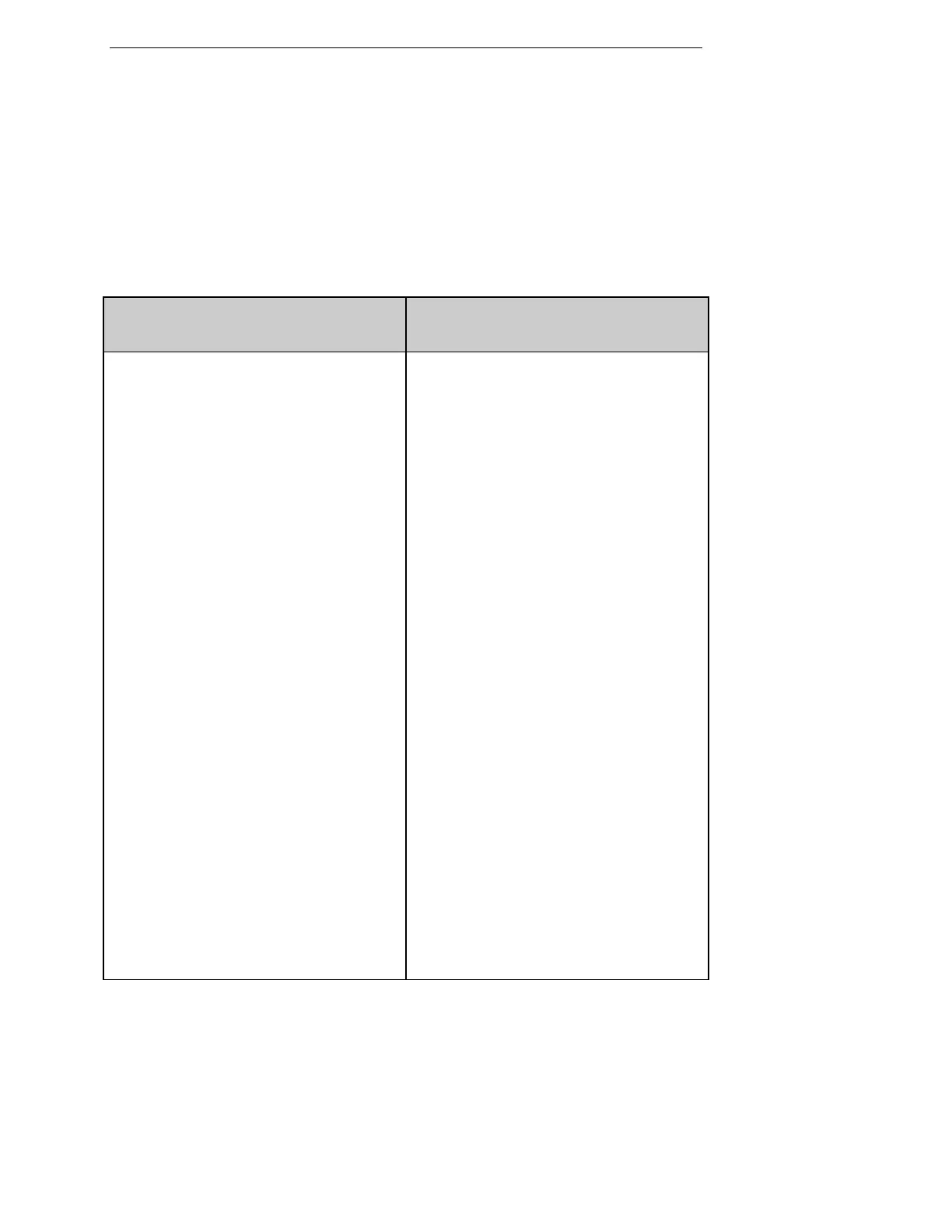

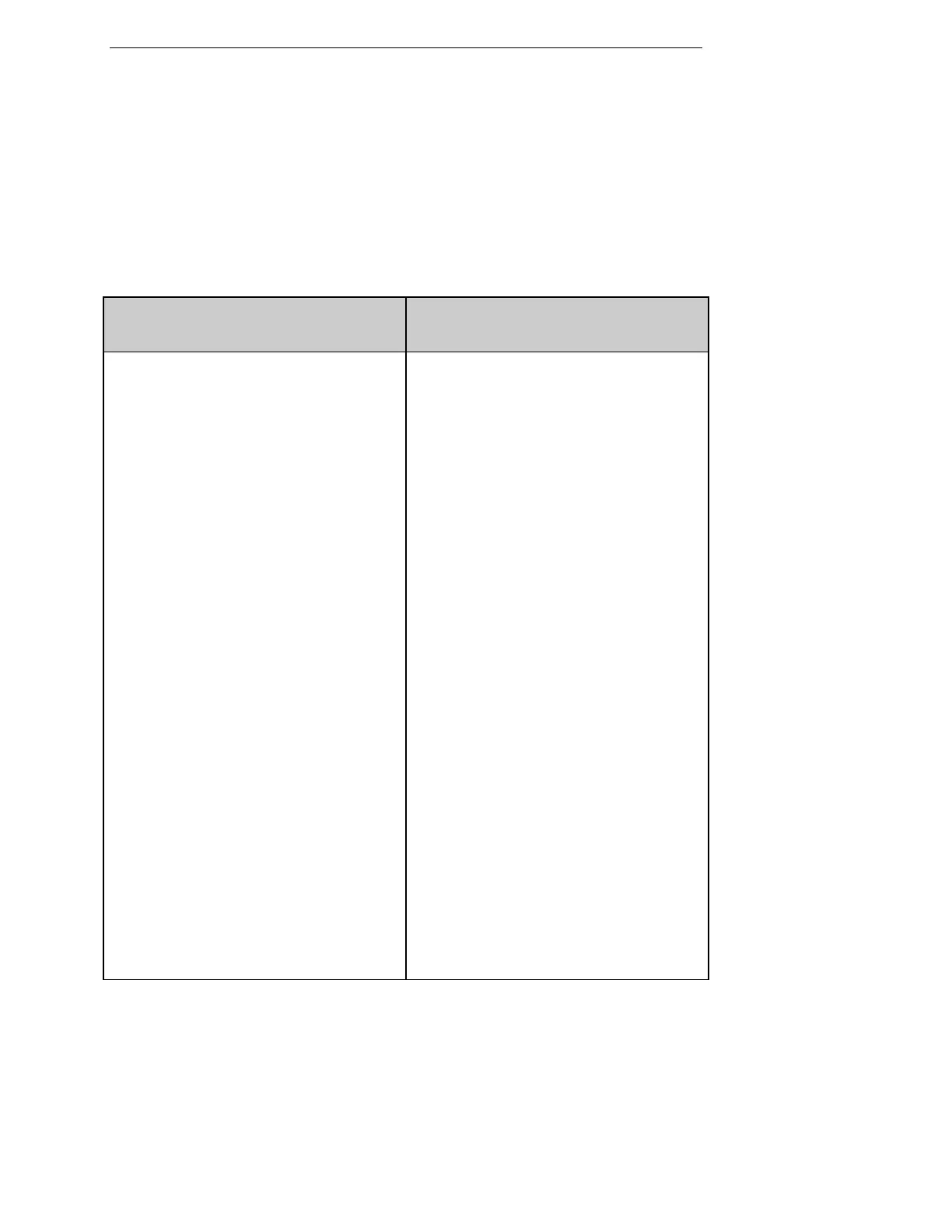

7-DAY PREVENTIVE

MAINTENANCE SCHEDULE

SUBJECT ACTION

• Bridge Section

• Conditioning Device

• Control Program and Recipe Data,

Calibration Variable Values

• Coolant/Table Temperature Readings

• Elevator/Robot Section

• Fluid/Solenoid Cabinet

• Machine Cabinet

• Polish Section

• Screen and Drain Pans for Table(s),

Elevators, Shuttle

• Single Table Shuttle Assembly

Clean and check:

Bridge covers, spindles, vacuum chucks.

Check conditioning device for cleanliness and

condition. Clean pan.

Backup after every change session.

Crosscheck coolant and table temperature

readings.

Clean and Check:

Elevator platforms and uprights, elevator

tanks inside and out, elevator bases, robot “R”

axis arm.

Fluid/solenoid cabinet leak check.

Clean operator doors inside and out.

Clean and check each of the following:

Conditioning arm, splash ring, table top and

sides, table pan, back splash shield, slurry

motor panel, and inside of operator doors.

Clean screen and drain pans for table(s),

elevators, and shuttle.

Clean and check:

Load chucks, load rings, load station buckets,

cleaning station devices, cleaning station

rollers, cleaning station buckets, upper and

lower shuttle plates.

Loading...

Loading...