Maintenance Model 6DS-SP Planarizer

8 - 8 Version 4.0 - February 1998

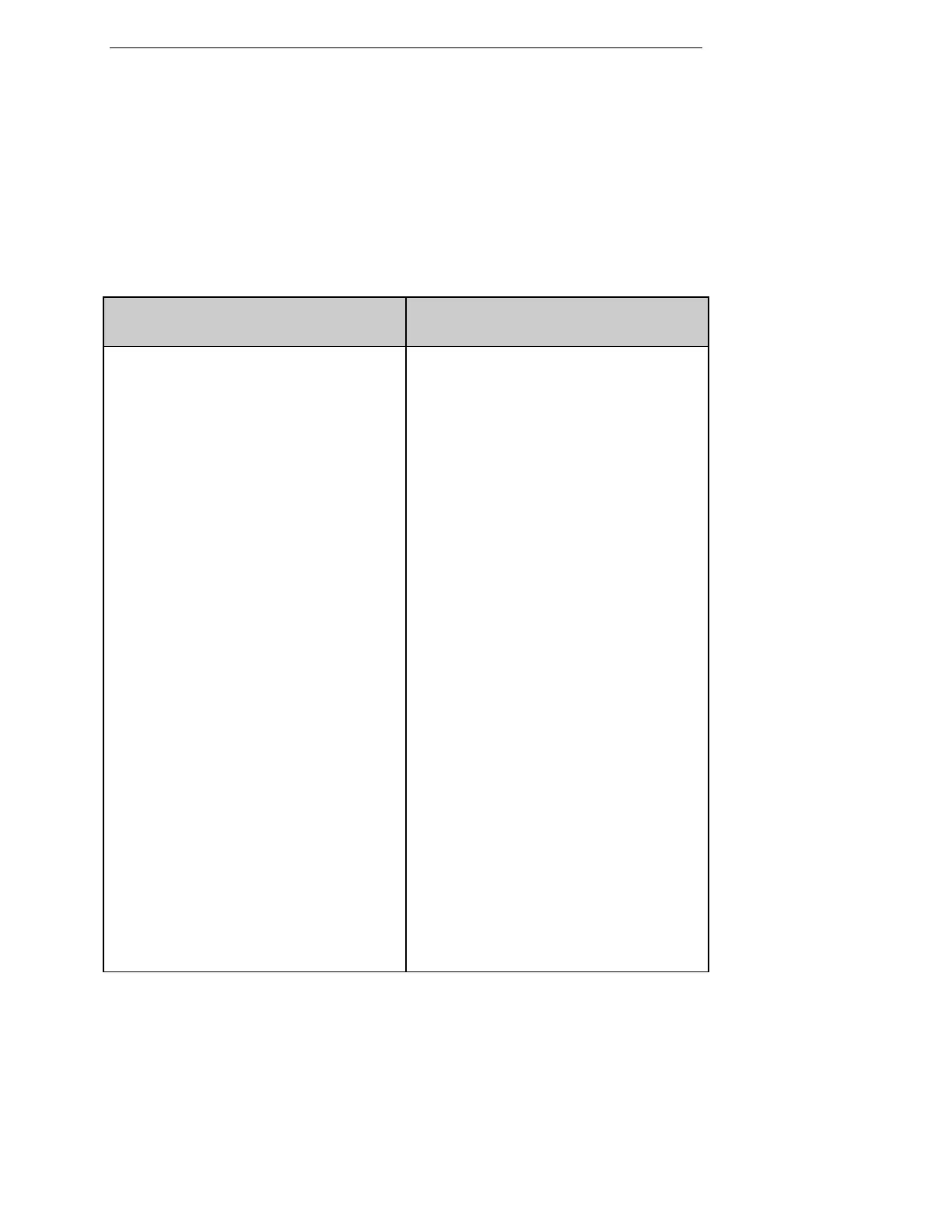

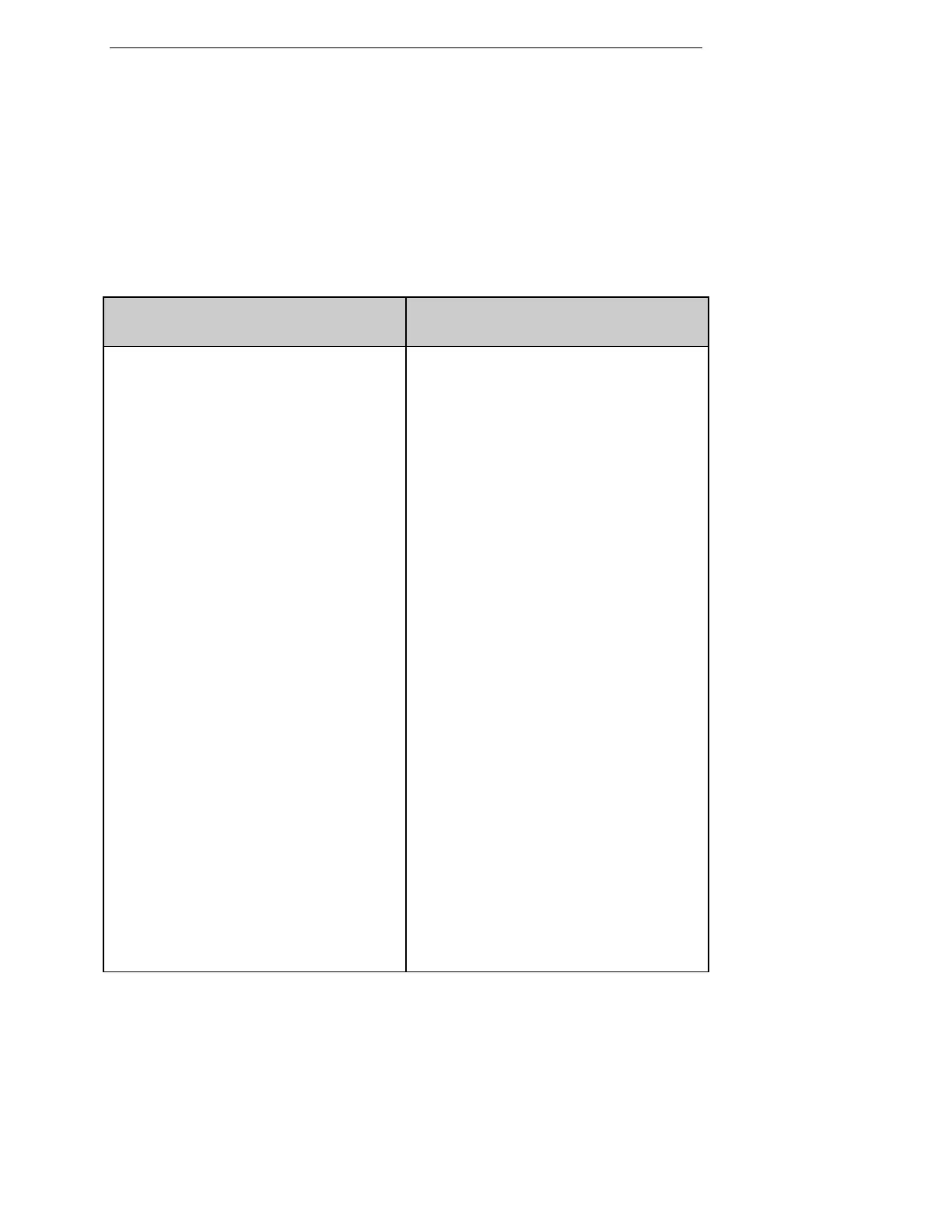

28-DAY PREVENTIVE

MAINTENANCE SCHEDULE

SUBJECT ACTION

• Air Supply Regulation

• Bridge Assembly

• Bridge Drive Belt

• Bridge Lubricator, Bridge Rails,

Leadscrew Lubrication

• Back Pressure

• Cleaning Stations

• Conditioning Arm

• Conditioning Arm Downforce

• Conditioning Arm Speed

• Elevators

• Load Chuck Raise Pressure

Check air supply regulator for filter

cleanliness and gauge settings.

Check:

Bridge centered over table 1 at table 1

position.

Bridge centered over load stations at load

position.

Inspect for cracking and fraying; check

individual cogs of belt for worn spots and

cracks; replace if signs of wear are evident.

Check belt for proper tension.

Check and fill the bridge lubricator as needed.

Inspect the bridge leadscrew and rails for the

presence of lubrication. Adjust as needed.

(Use Shell Tellus 10 or equivalent.)

Check for left and right spindle back pressure;

calibrate as needed.

Check alignment; adjust as needed.

Check:

Center of table position.

Brush rotation RPM’s.

Check and calibrate the conditioning arm

downforce.

Check/adjust conditioning arm speed.

Check elevator light sensor.

Check and adjust.

Loading...

Loading...