Strasbaugh Preventive Maintenance Schedules

Version 4.0 - February 1998 8 - 9

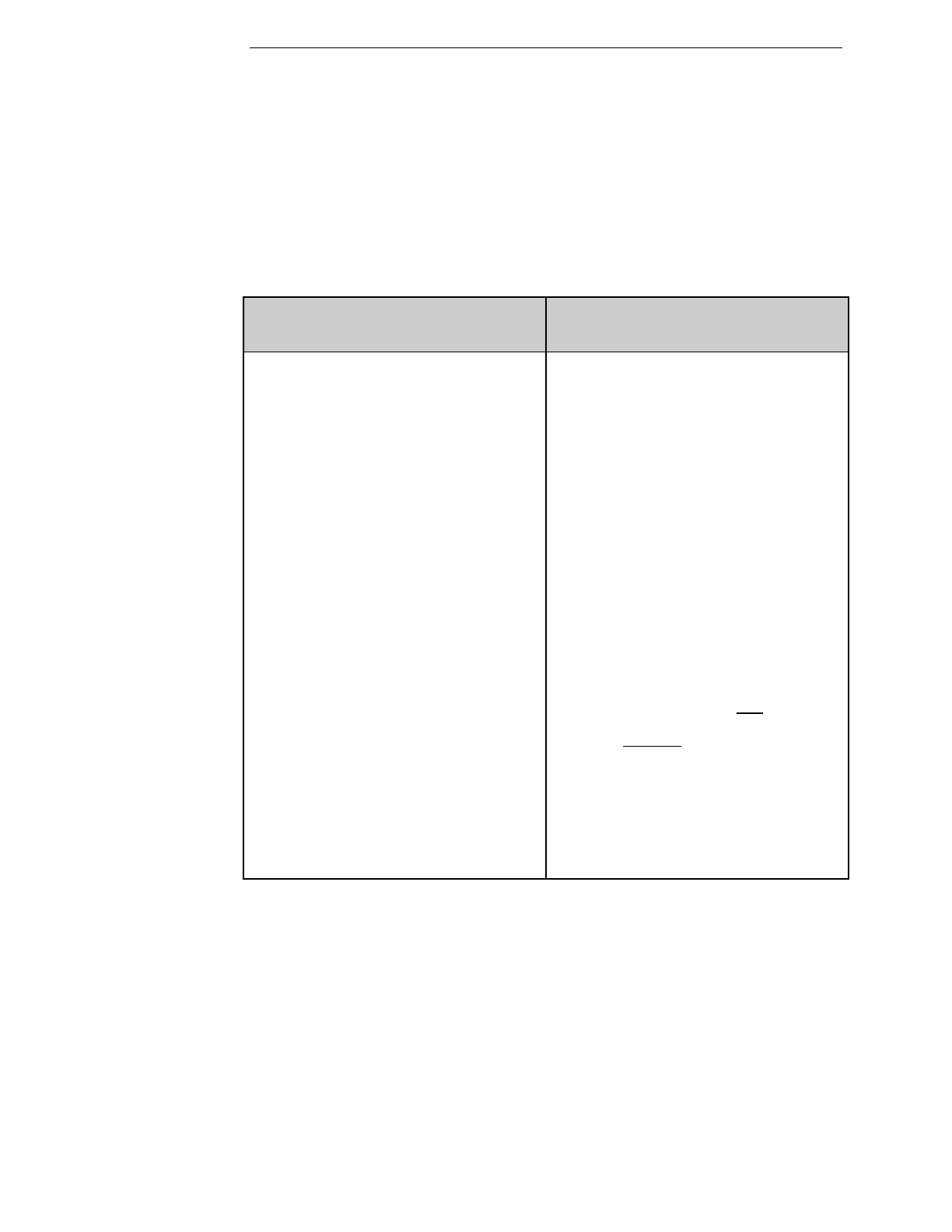

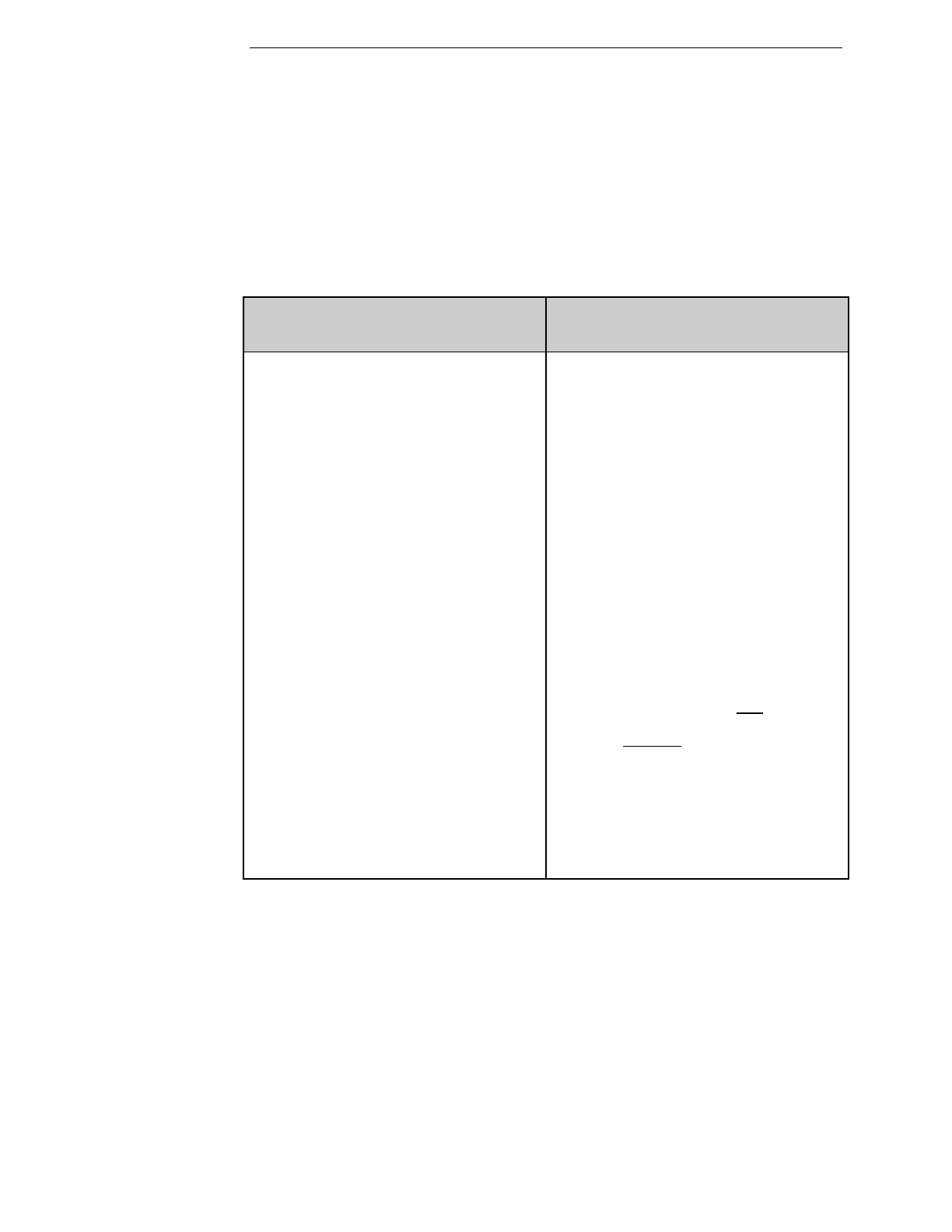

28-DAY PREVENTIVE

MAINTENANCE SCHEDULE

SUBJECT ACTION

• Load Station Alignment

• pH Transmitter

• Polish Downforce

• Power On, Machine On Indicator

Lamps

• Robot

• Robot Travel Rails and Leadscrew

• Safety Switches:

Emergency Off Switches

All Safety Interlock Switches Door

Switches

Operator and Polish Doors Interrupts

Check and calibrate. Adjust as needed.

Check and calibrate. Refer to Software

Calibration chapter and Signet

manufacturer’s data.

Check and calibrate polish downforce for both

left and right spindles.

Check for proper operation of Power On and

Machine On indicator lamps. Replace as

needed.

Check:

Robot travel position at elevators and load

stations.

Wafer pickup at send elevators.

Wafer placement and pickup at load stations.

Wafer placement at receive elevators.

Inspect and clean. Lubricate rails with Super

Lube grease or equivalent as needed.

Lubricate leadscrew with Super Lube grease

or equivalent as needed.

Check for proper operation. Adjust as needed.

Loading...

Loading...