Maintenance Model 6DS-SP Planarizer

8 - 10 Version 4.0 - February 1998

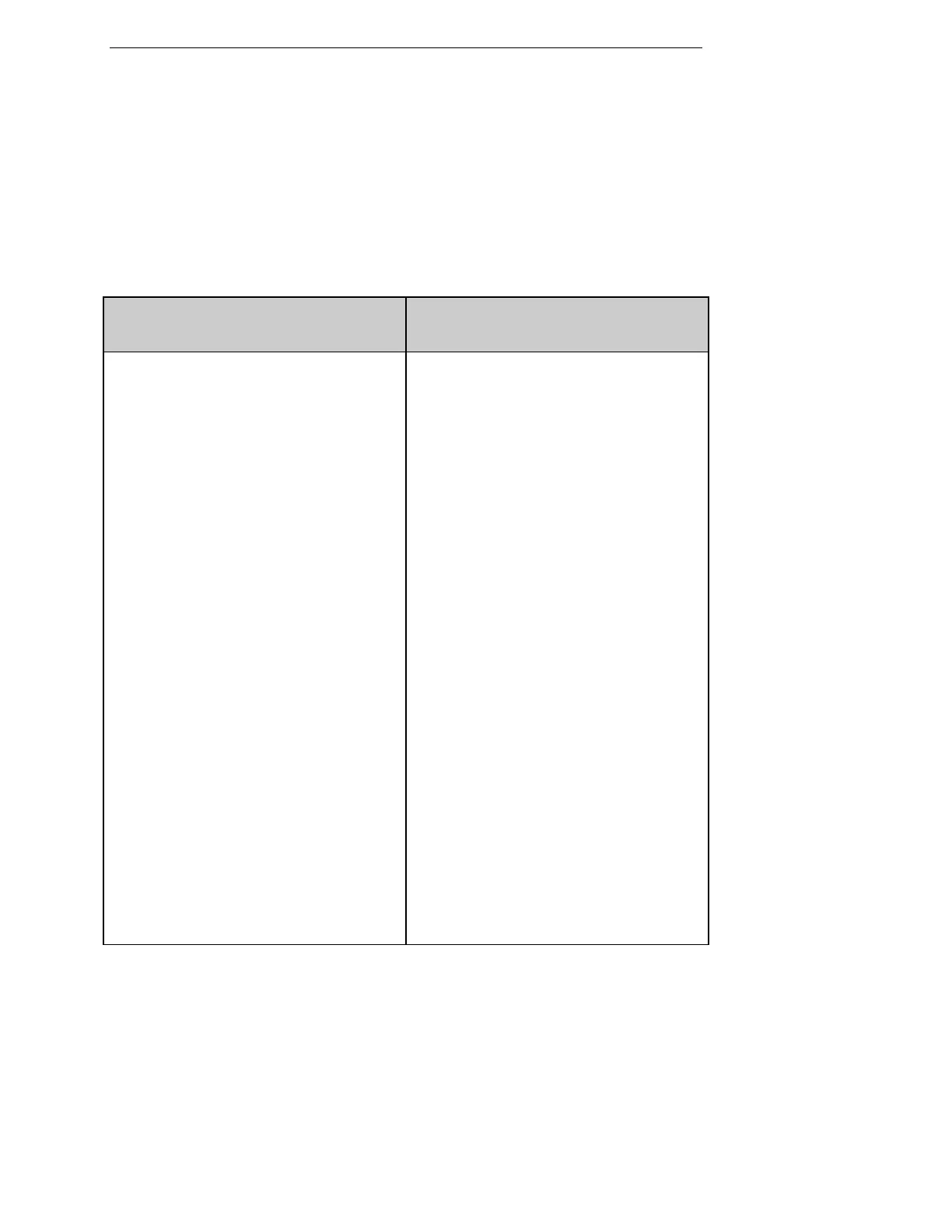

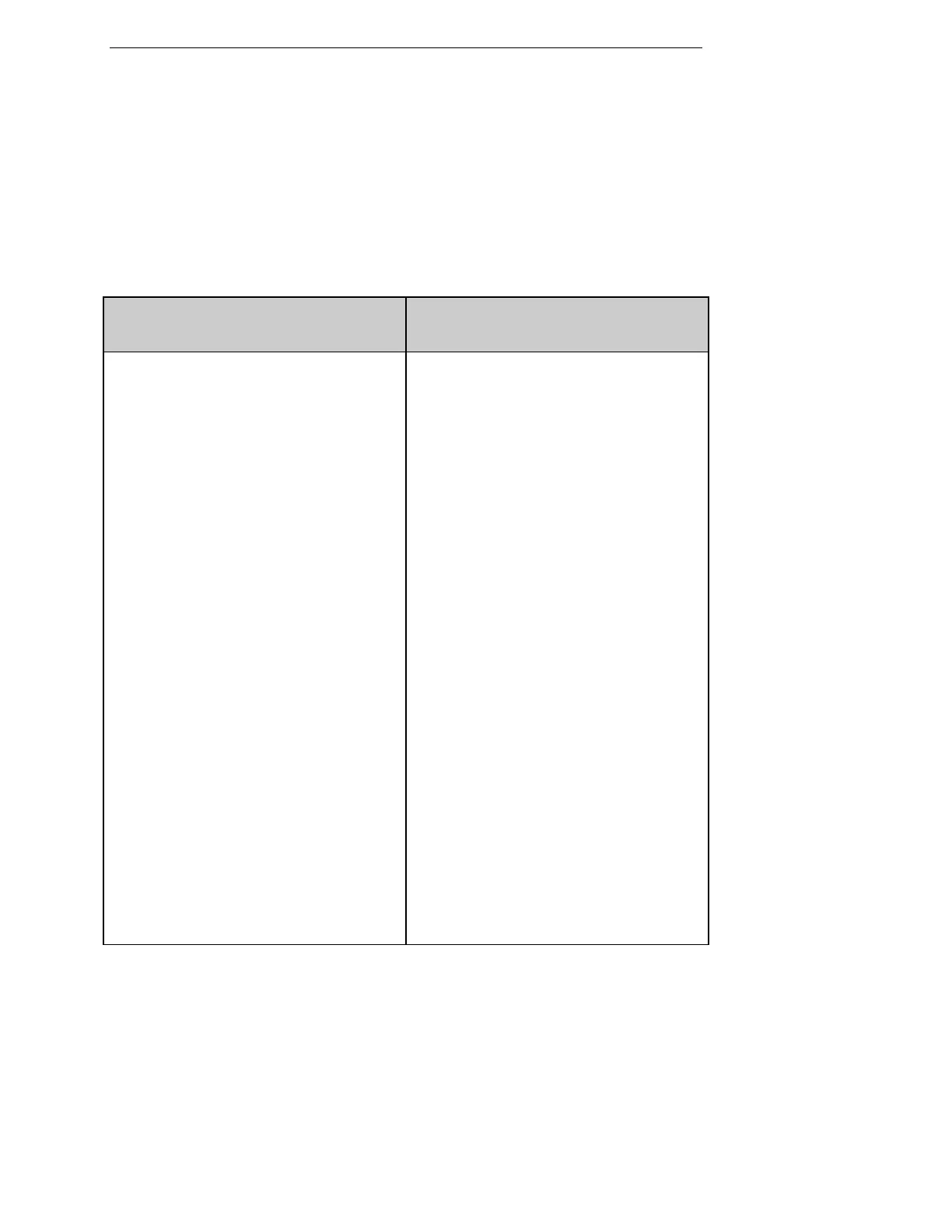

28-DAY PREVENTIVE

MAINTENANCE SCHEDULE

SUBJECT ACTION

• Shuttle Travel Alignment

• Slurry Diaphragm Pump Pressure

• Slurry 1 Flow, Slurry 2 Flow, Pump 3 (if

installed) Flow

• Spindle Alignment

• Spindle Back Pressure Filters (Left And

Right)

• Spindle Blow Off Pressure

• Spindle Vacuum Chuck Alignment

• Table Alignment

• Table 1

• Table 2/Shuttle

• Table and Spindle RPM

• Wafer Blowoff Pressure

• Wafer Detection Vacuum Sensor

Check and calibrate. Adjust as needed.

Check and adjust.

Check and calibrate flow.

Check and adjust left and right spindle

alignment/runout.

Check; replace as needed.

Check and adjust.

Check and adjust left and right spindle

vacuum chuck alignment/runout.

Check and adjust table alignment/runout.

Check table sweep.

Check:

Load ring tray alignment.

Load chucks for leveling.

Measure RPM of table(s) and left and right

spindle.

Check and adjust.

Check and calibrate.

Loading...

Loading...