Maintenance Model 6DS-SP Planarizer

10 - 60 Version 4.0 - February 1998

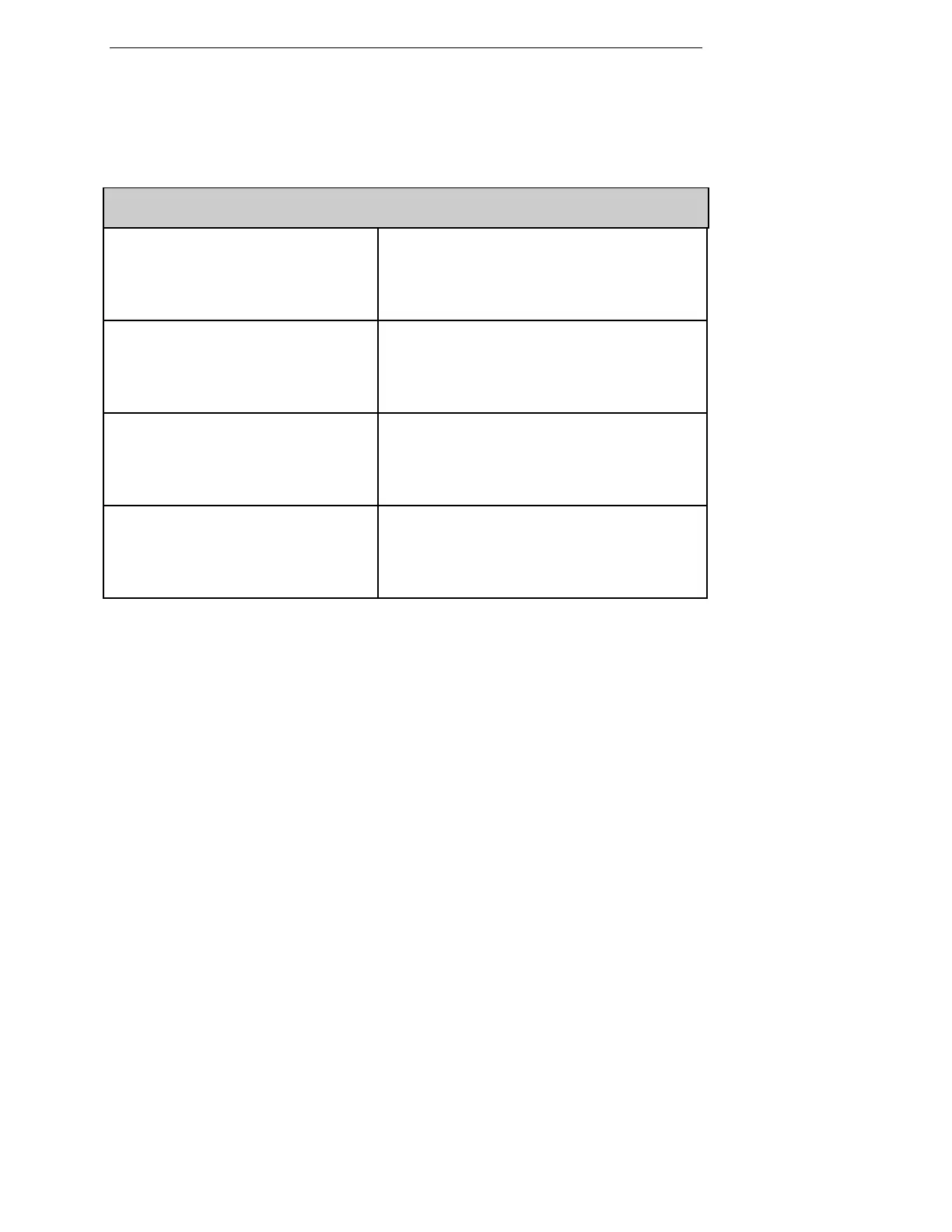

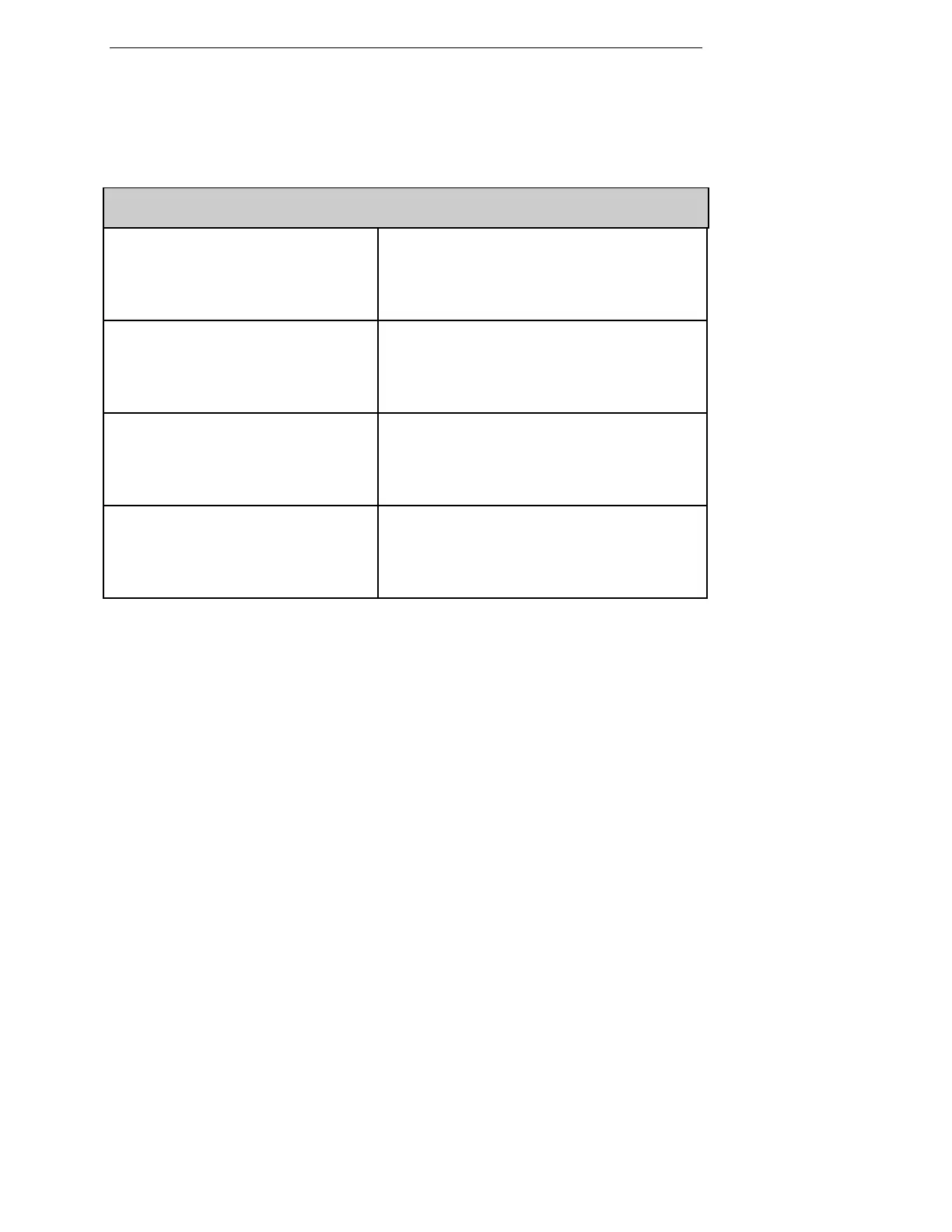

CALIBRATION VARIABLES SET DURING THIS PROCEDURE

80 Left send offset to slot 0

• Nominal value for pre-3/95

elevators: 2 to 3 in.

• Nominal value for post-3/95

elevators: 1 to 2 in.

The distance, in inches, required to raise the left

send elevator from the home position to a point

that places an imaginary "slot 0" at the wafer

loading plane.

81 Right send offset to slot 0

• Nominal value for pre-3/95

elevators: 2 to 3 in.

• Nominal value for post-3/95

elevators: 1 to 2 in.

The distance, in inches, required to raise the right

send elevator from the home position to a point

that places an imaginary "slot 0" at the wafer

loading plane.

82 Left recv offset to slot 0

• Nominal value for pre-3/95

elevators: 2 to 3 in.

• Nominal value for post-3/95

elevators: 1 to 2 in.

The distance, in inches, required to raise the left

receive elevator from the home position to a point

that places an imaginary "slot 0" at the wafer

loading plane.

83 Right recv offset to slot 0

• Nominal value for pre-3/95

elevators: 2 to 3 in.

• Nominal value for post-3/95

elevators: 1 to 2 in.

The distance, in inches, required to raise the right

receive elevator from the home position to a point

that places an imaginary "slot 0" at the wafer

loading plane.

A. BEFORE YOU BEGIN

Tools Required

• precision scale (accurate to .03125 in.)

• test wafer

• test cassette

Turn Machine Power On and Perform Home Sequence Routine

Follow the procedures detailed in the Operator Functions chapter of the 6DS-SP

Operations manual.

Loading...

Loading...