Maintenance Model 6DS-SP Planarizer

10 - 76 Version 4.0 - February 1998

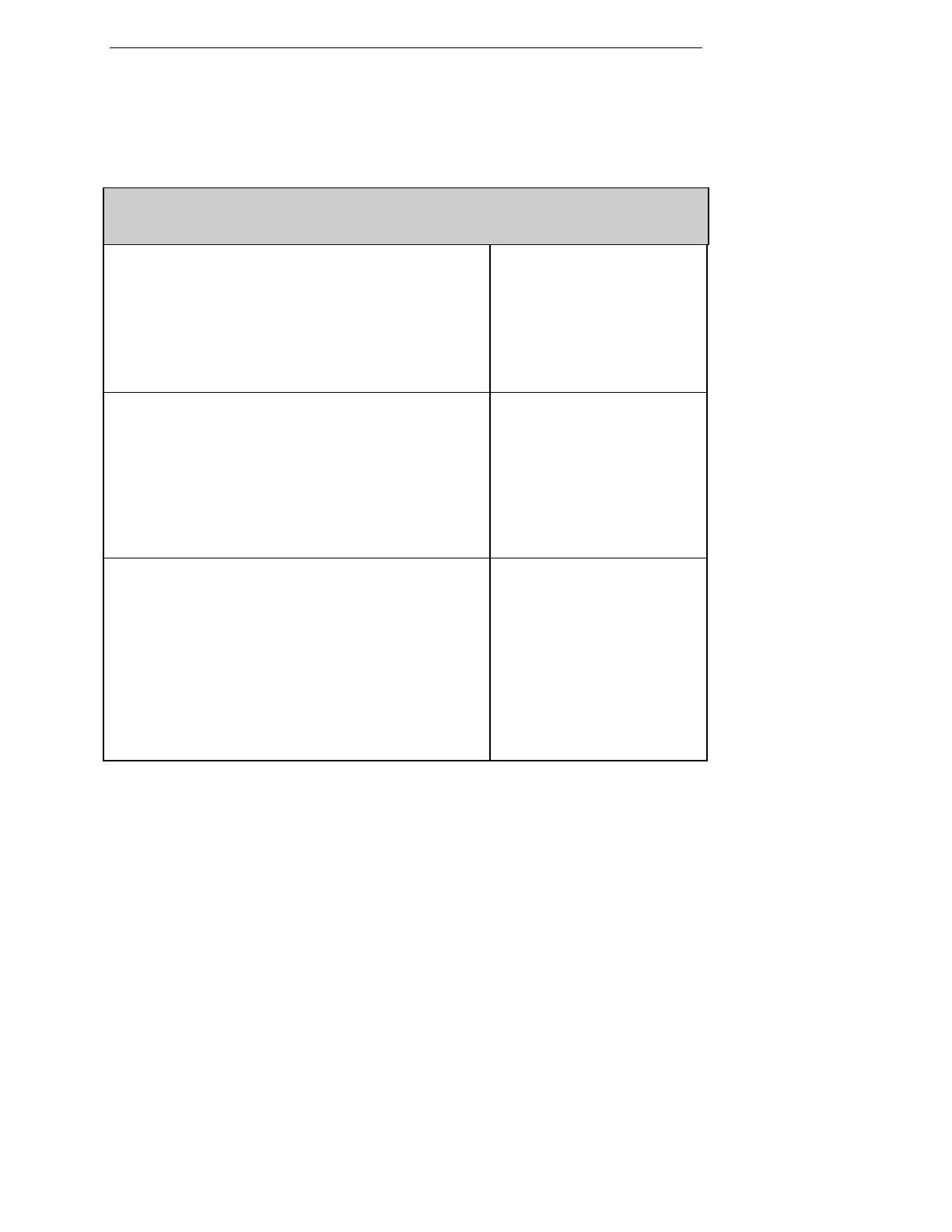

CALIBRATION VARIABLES SET DURING THIS PROCEDURE

116 Robot up/dn top position

• Nominal value for RTZ Robot and 3-, 4-, 5-, 6-, or

8-inch wafers: .5 in.

• Nominal value for two arm robot and 8-inch

wafers (.25-in. slot spacing): between .2 and .5 in.

• Nominal value for two arm robot and 3-, 4-, 5-, or

6-inch wafers (.1875-in. slot spacing): between .2

and .5 in.

Value, in inches, to move the

robot's up/down axis to a

position below the home

position that is slightly above

wafers in a cassette.

117 Robot up/dn middle position

• Nominal value for RTZ Robot and 3-, 4-, 5-, 6-, or

8-inch wafers: .56 in.

• Nominal value for two arm robot and 8-inch

wafers (.25-in. slot spacing): .11 in. greater than

the value of variable 116

• Nominal value for two arm robot and 3-, 4-, 5-, or

6-inch wafers (.1875-in. slot spacing): .04 in.

greater than the value of variable 116

Value, in inches, to move the

robot's up/down axis to a

position below the home

position that will hold a wafer

in the center of the slot in a

cassette.

118 Robot up/dn bottom position

• Nominal value for RTZ Robot and

3-, 4-, 5-, 6-, or 8-inch wafers: .62 in. to .64 in.

• Nominal value for two arm robot and 8-inch

wafers (.25-in. slot spacing): .19 in. greater than

the value of variable 116

• Nominal value for two arm robot and 3-, 4-, 5-, or

6-inch (.1875-in. slot spacing) wafers: .1 in. greater

than the value of variable 116

Value, in inches, to move the

robot's up/down axis to a

position below the home

position that will contact a

wafer resting at the bottom of a

slot in a cassette.

Note: .62 is used without

dunk/send mode; when in

dunk/send mode, approx. .64 is

used.

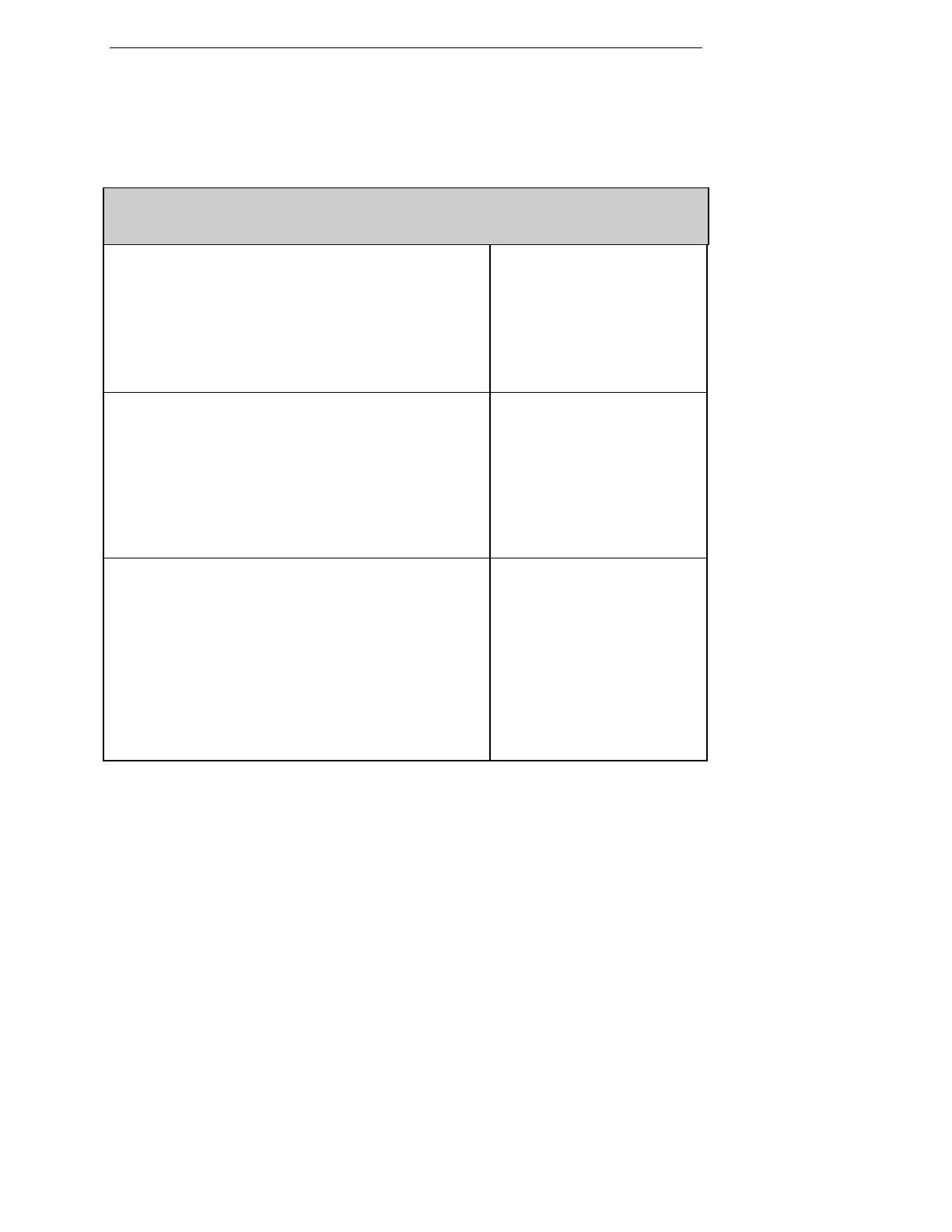

Setting Goals for Cassettes with Slot Spacing Other than Those Listed Above and

Processing of Other Wafer Sizes

Check the cassette slot spacing and make appropriate adjustments in the values

for variables 116, 117, and 118 based upon the desired relationships between the

three positions as shown in the two tables above.

Loading...

Loading...