Maintenance Model 6DS-SP Planarizer

10 - 80 Version 4.0 - February 1998

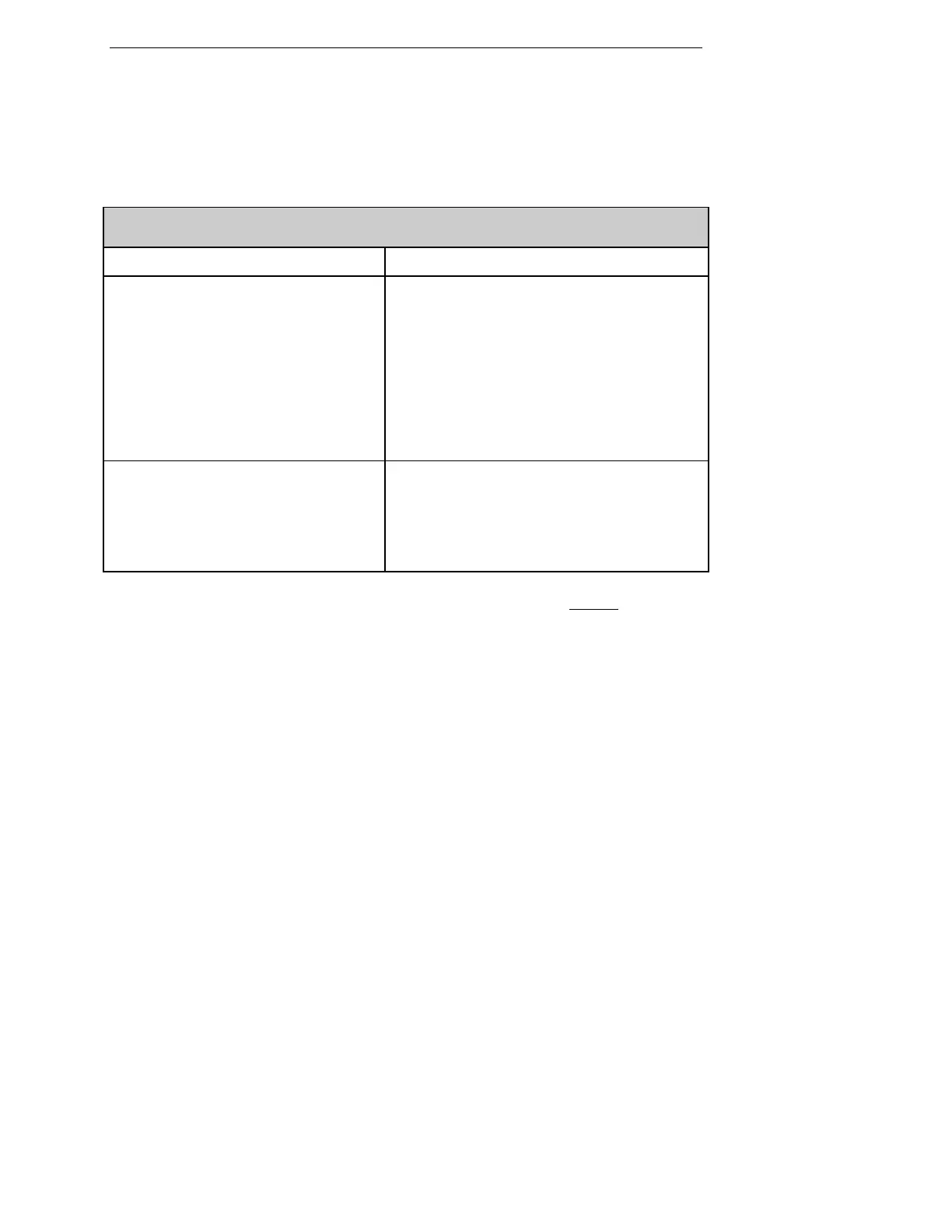

CALIBRATION VARIABLES SET DURING THIS PROCEDURE

At the Elevators: At the Load Stations:

76 “RTZ robot send rotate position”

Calibrates the rotation of the RTZ robot to

aim the arm into send cassettes. -4000

counts is 90 degrees CCW from (*) zero

position.

78 "RTZ robot LT ld rotate pos'n" Calibrates

the rotation of the RTZ robot to aim the arm into

the left load station area.

• Single Table Machines: Nominally set to

4000 counts which is 90 degrees CW from (*)

zero position.

• Two Table Machines: Nominally set to 5100

counts which is about 115 degrees CW from (*)

zero position.

77 “RTZ robot receive rotate position”

Calibrates the rotation of the RTZ robot to

aim the arm into receive cassettes and the

optional scrubber station. 4000 counts is

90 degrees CW from

(*) zero position.

79 "RTZ robot RT ld rotate pos'n"

Calibrates the rotation of the RTZ robot to aim

the arm into the right load station area.

Nominally set to 2900 counts is about 75 degrees

CW from (*) zero position.

* The robot arm’s zero (home) position is factory set to be parallel to the

linear robot axis. If the arm is grossly unparallel to the robot linear axis,

consider a factory adjustment.

A. BEFORE YOU BEGIN

Tools Required

• none

Turn Machine Power On and Perform Home Sequence Routine

Follow the procedures detailed in the Operator Functions chapter of the 6DS-SP

Operations manual.

B. SET CALIBRATION VARIABLES 76, 77, 78, 79

1. At the Calibration/Configuration Menu, select Page Down to display

variable 76, RTZ robot send rotate position.

Loading...

Loading...