3

Electrical Supply

THIS EQUIPMENT MUST BE EARTHED

Before connection please read and understand this instruction

manual and ensure that the line supply corresponds to that

shown on the rating plate. Bibby Scientific rotary evaporators

require a supply rated at 220-240V, 50/60Hz, single phase,~.

The power consumption of the rotary evaporator is 50W.

F3.15AL (20x5mm) fuses fitted in both live and neutral lines.

IF IN DOUBT CONSULT A QUALIFIED ELECTRICIAN

The unit is supplied with two mains leads fitted with IEC plugs for

connection to the instrument. One has a U.K. 3 pin plug and the

other has a 2-pin “Shuko” plug for connection to the mains.

Choose the lead appropriate for your electrical installation and

discard the other.

Should neither lead be suitable, take the lead with the U.K. plug and

replace the plug with a suitable alternative. This involves cutting off

the moulded plug, preparing the cable and connecting to the

rewireable plug in accordance with its instructions.

IT IS IMPORTANT THAT THIS OPERATION SHOULD ONLY BE

UNDERTAKEN BY A QUALIFIED ELECTRICIAN

The wires in the mains cable are coloured as follows:

BROWN - LIVE

BLUE - NEUTRAL

GREEN/YELLOW - EARTH

The unit is fitted with an IEC socket at the rear of the instrument for

connection of the mains lead. The appropriate mains lead should be

connected BEFORE connection to the mains supply.

Should the mains lead need replacement a cable of 1mm

2

of

harmonised code H05W-F connected to an IEC 320 plug should be

used.

N.B. The UK mains lead is protected by a 10A fuse mounted in the

plug top.

Safety Advice before Use

1. If the jacking mechanism is to be raised without the

glassware fitted great care must be taken. Without the

weight of the glass the jack will rise rapidly and can cause

damage to the mechanism. Unlock the jack carefully while

applying downward pressure to control the movement.

2. As the apparatus is likely to be used under vacuum, before

operation, examine all glassware carefully for scratches or

chemical etching. Use of damaged glassware under

vacuum could result in an implosion. In any case it is

recommended that the apparatus be operated behind a

safety screen.

3. Do not use the equipment in a hazardous atmosphere or

for mixing of hazardous materials.

4. Special care should be taken when using the equipment

with flammable solvents. The unit is not spark or explosion

proof.

5. In case of mains interruption, a fault or mechanical failure,

the unit will continue to operate on removal of the fault.

6. Beware of safety issues associated with rotating glassware

and when jacking glassware up and down.

Assembly

If the jacking mechanism is to be raised without the glassware

fitted great care must be taken. Without the weight of the

glass the jack will rise rapidly and can cause damage to the

mechanism. Unlock the jack carefully while applying

downward pressure to control the movement.

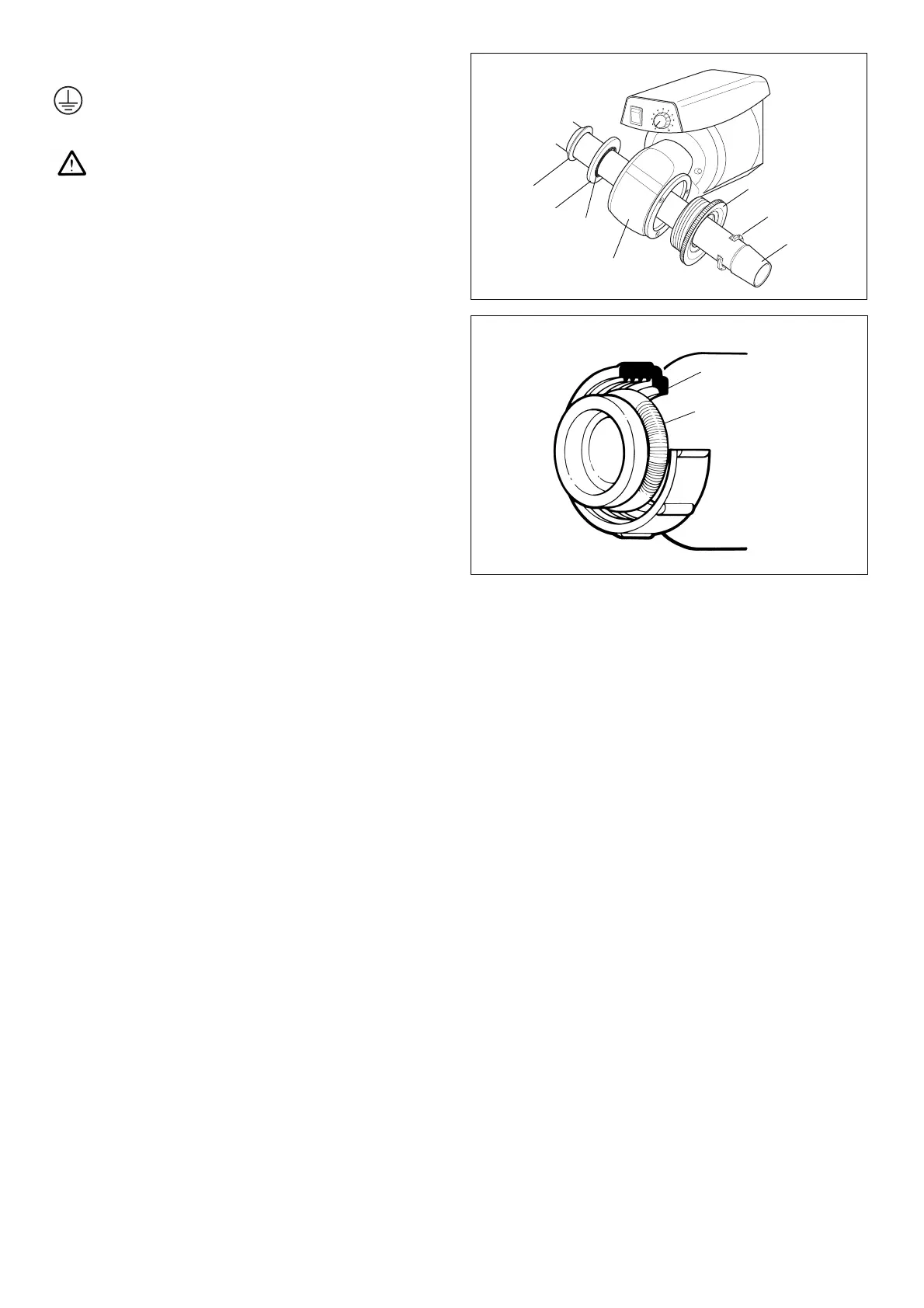

1. Unpack the rotary evaporator and identify the following

components:

Item Component Catalogue

No Number

1 Condenser RE100/CO or RE200/VC or

RE200/CF and RE200/CFD

2 Conical joint clip KCM29

3 Feed/vacuum release adapter RE100/VR

4 Florentine flask 1L FD1L/4RE

5 Receiving flask 1L RE100/RF/1L

6 Rotary evaporator motor stand RE300/MS

7 Spherical joint clip JC35

8 Vapour tube RE100/VT or RE100/VT/CF

9 Grey retaining cap

10 Circular metal spring

11 Vacuum seal

12 Sub-seal

13 Retaining clip

- UK lead

- European lead

- Spare fuse

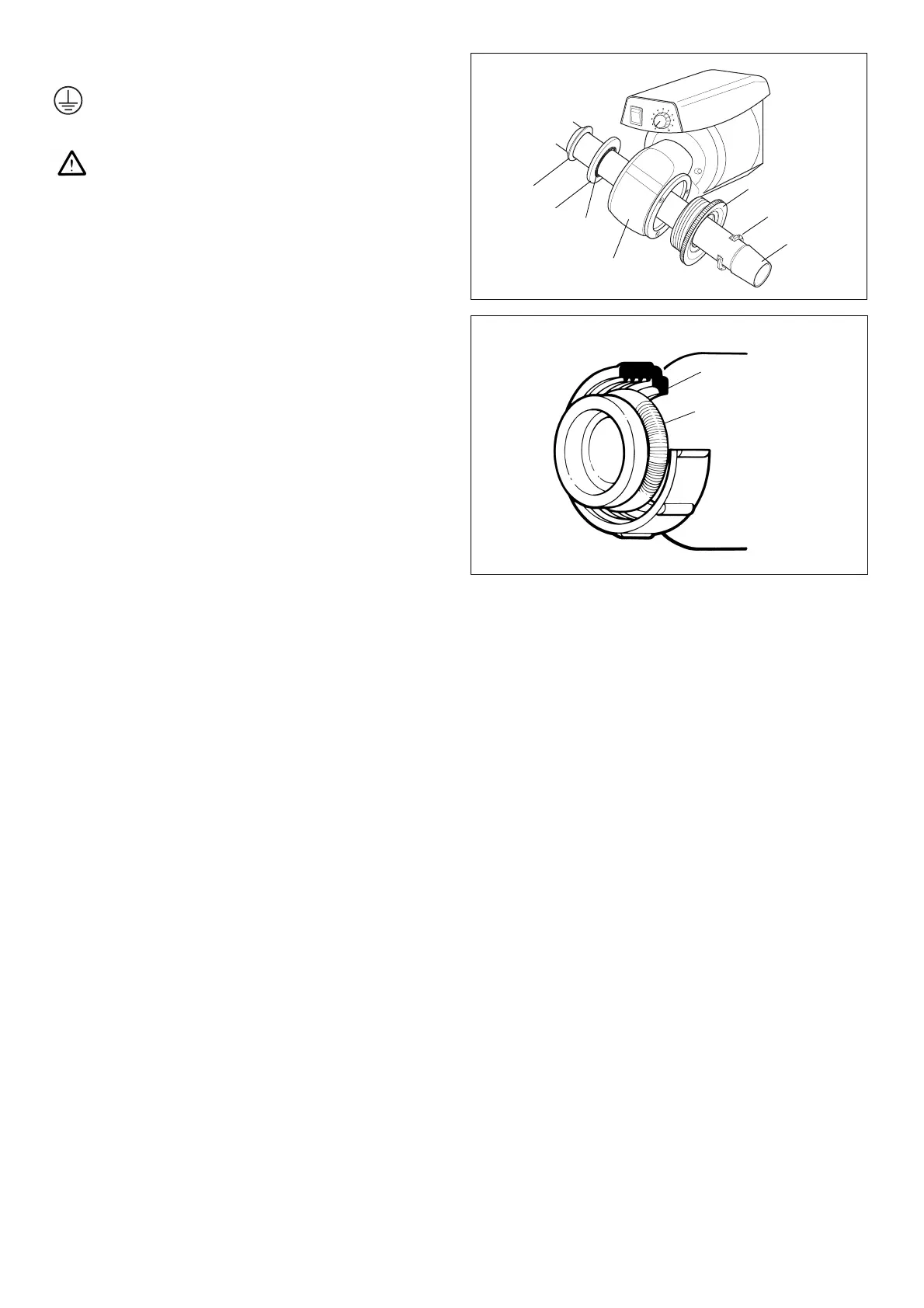

12

11

Bearing house

Figure 2

Figure 3

Plastic screw bush

10

1

9

13

8

Spring

All components are

included in the rotary

evaporator motor stand

box

Loading...

Loading...