CONDENSER IOM MANUAL

25

refrigerant charge before attempting repairs. Adjacent piping

must be thoroughly cleaned by removing all paint, dirt and oily

film. Use wire brush, sandcloth or sandpaper and wipe the area

with clean, dry cloths. Protect nearby parts from heat damage

by wrapping with water-soaked cloths

4.2.3 Refrigerant Piping

When replacing components within the cabinet, the following

consumable materials are recommended: When brazing copper-

to-copper connections (piping liquid line or suction line), use a

phosphorus copper brazing alloy with 15% silver. General purpose

silver brazing alloy with 45% silver is to be used for copper-to-

brass or copper-to steel.

For liquid line repairs at the drier, strainer, sight glass, or expansion

valve, use a 95% tin to 5% antimony solder with flux. When

component replacement is complete, remove all traces of flux.

After any repair, pressure check the system, checking for leaks

prior to recharging the system.

4.2.4 Electrical System

All electrical connections should be checked to be sure that

they are tight and properly made. Check all switches,

contactors and wiring. Contactors should be examined and

replaced if the contact pads are worn or pitted.

4.3 Troubleshooting

Turn off all power to the unit before conducting any

troubleshooting procedures unless the procedure specifically

requires the system to operate. For troubleshooting purposes,

the system may be operated with the electric box open by

using a pair of channel lock pliers to turn the shaft of the

main power disconnect switch to the “On” position. When

the switch is turned on, high voltage will be present inside

the box. Exercise caution to prevent injury. Keep hands,

clothing and tools clear of the electrical terminals and rotating

components. Verify that your footing is stable.

WARNING

This equipment should be serviced and repaired by a

journeyman or a qualified refrigeration technician only.

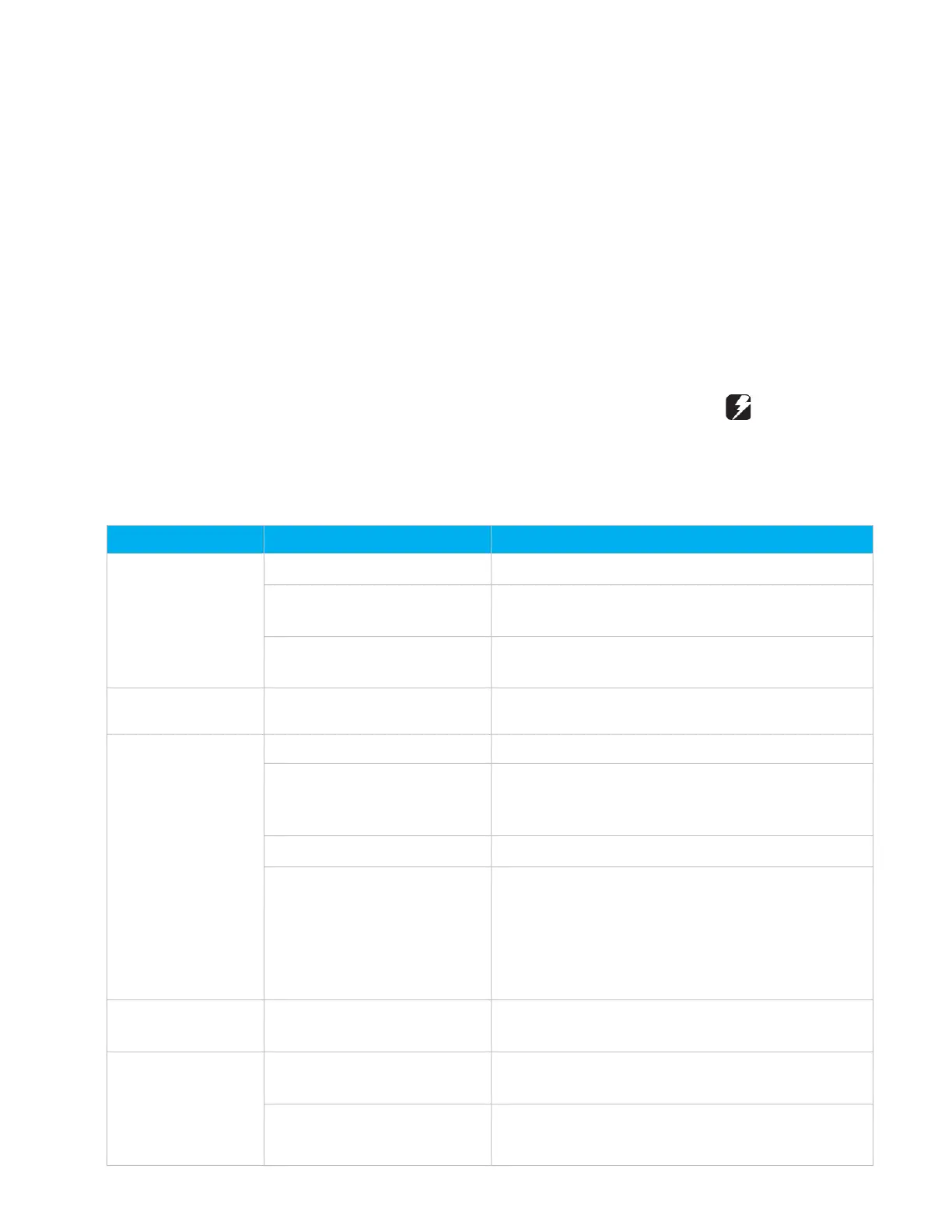

Symptom Probable Cause Recommendation

Unit Fails to Start

Incorrect phasing or voltage.

Correct phase or voltage input.

Power failure Check power source, power input and fuses. Check control

Overload protection tripped Check pressure/temperature operating switches and

motor. Replace as needed

Control is Erratic

Wiring improperly connected or

Check wiring against schematic diagram

Condenser Head

Pressure Too High

Low condenser airflow. (Indicated

by excessive warm air leaving the

Open air passages. Clean coil. Check con- denser fan(s).

Overcharge of refrigerant Reclaim excess refrigerant from system

Condenser fan not operating Check main voltage power source to unit.

Check fan motor, contractor, fan cycling switch or fan

speed controller.

Check pressure/temperature operating switches and

motor. Replace if needed.

Condenser Fan not

Operating

Non-condensable gas or air in

the system

Reclaim system, pull 500-micron vacuum and recharge.

Install new drier/strainer.

Condenser Head

Pressure Too Low

Loss of refrigerant (indicated by

bubbles in sight glass).

Locate and repair leak. Recharge system.

Condenser fan controls not set

properly

Adjust or repair controls.

Loading...

Loading...