6

|

English subzero.com

|

7

SITE PREPARATION

CONCRETE WEDGE ANCHOR INSTALLATION:

1 Drill a 10 mm diameter hole any depth exceeding the

minimum embedment. Clean the hole or drill additional

depth to accommodate drill nes.

2 Assemble the washer and nut ush with the end of

anchor to protect threads. Drive the anchor through the

material to be fastened until the washer is ush with the

surface material.

3 Expand the anchor by tightening the nut 3–5 turns past

hand-tight position or to 34 newton-meters of torque.

WARNING

Verify there are no electrical wires or plumbing in the

area which the screws could penetrate.

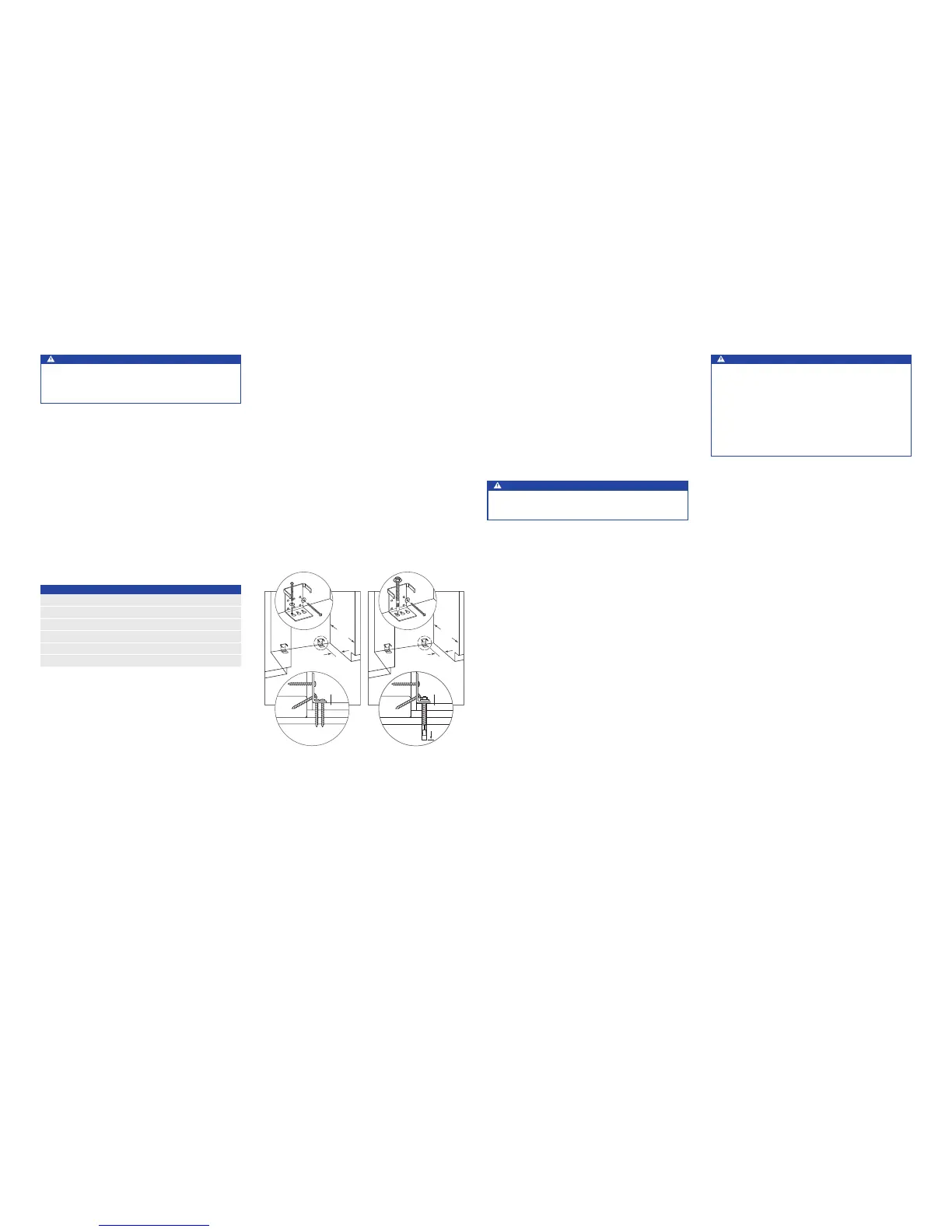

WOOD FLOOR APPLICATION

After properly locating the anti-tip brackets in the opening,

drill pilot holes 5 mm diameter maximum in the wall studs or

wall plate. Use the #12 screws and washers to secure the

brackets. Verify the screws penetrate through the ooring

material and into wall studs or wall plate a minimum of 19

mm. Refer to the illustration below.

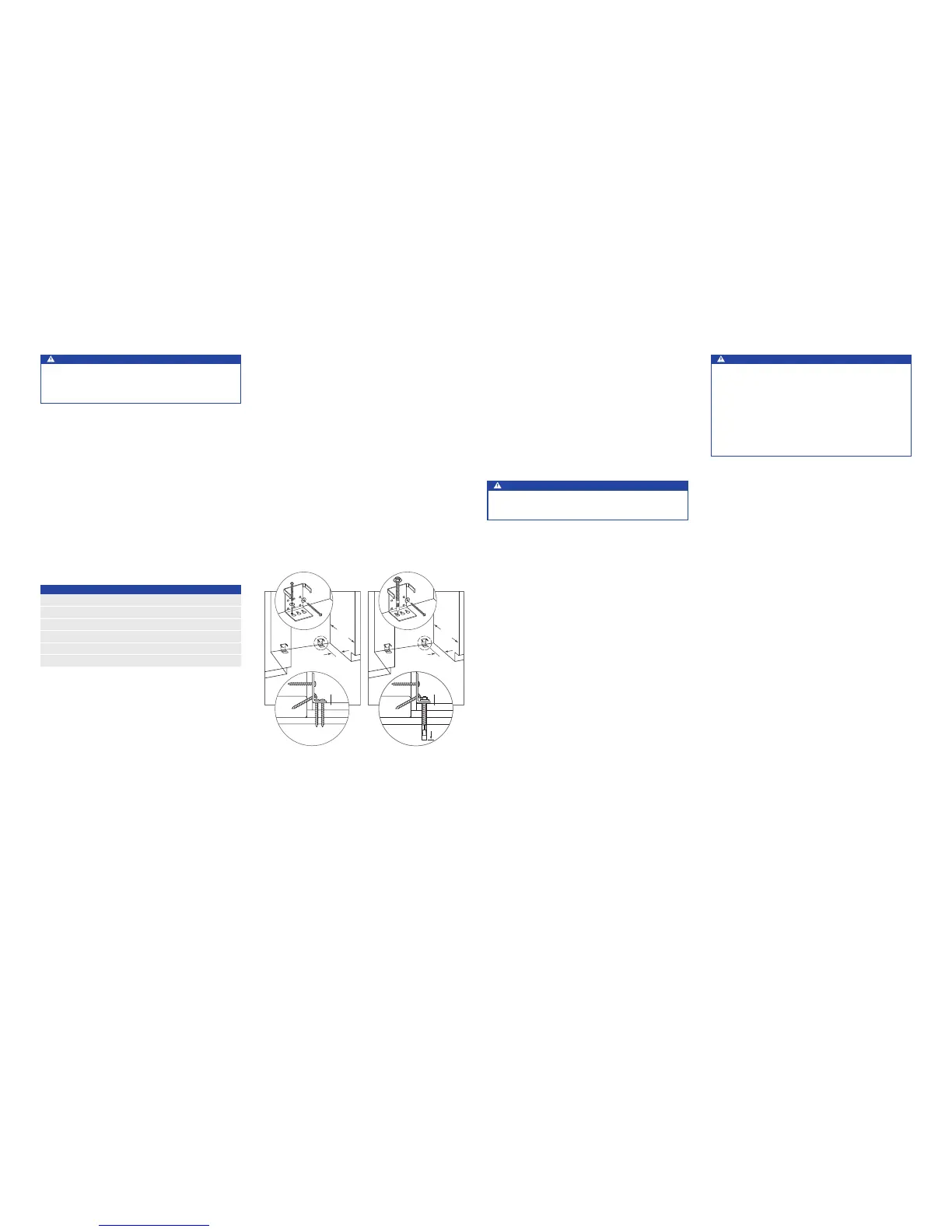

CONCRETE FLOOR APPLICATION

After properly locating the anti-tip brackets in the opening,

drill pilot holes 5 mm diameter maximum in the wall studs

or wall plate. Drill 10 mm diameter holes into the concrete a

minimum of 38 mm deep. Use the #12 screws and washers

to secure the brackets to the wall, and use the

3

/8" wedge

anchors to secure the brackets to the oor. Verify the screws

penetrate wall studs or wall plate a minimum of 19 mm.

Refer to the illustration below.

102 mm

MIN

610

mm

SUBFLOORING

WOOD FLOOR

WALL PLATE

FINISHED

FLOORING

102 mm

MIN

610

mm

SUBFLOORING

CONCRETE

FLOOR

WALL PLATE

FINISHED

FLOORING

1

1

/

2

"

(38)

min

SUBFLOORING

CONCRETE

FLOOR

WALL PLATE

FINISHED

FLOORING

38 mm

MIN

Wood floor.

Concrete floor.

Anti-Tip Bracket

WARNING

To prevent the unit from tipping forward and provide

a stable installation, the unit must be secured in place

with the anti-tip brackets.

The two anti-tip brackets must be installed exactly 610 mm

from the front of the opening to the back of the brackets

and a minimum of 102 mm from the sides of the opening.

This depth will increase to 665 mm for a ush inset installa-

tion based on 19 mm thick panels. Failure to properly posi-

tion the anti-tip brackets will prevent proper engagement.

Use all anti-tip bracket hardware as instructed for wood or

concrete oors.

IMPORTANT NOTE: For wood or concrete oor applications,

if the #12 screws do not hit a wall stud or wall plate, use the

#8 screws and #12 washers with the wall anchors.

IMPORTANT NOTE: In some installations the subooring or

nished oor may necessitate angling the screws used to

fasten the anti-tip brackets to the back wall.

ANTI-TIP HARDWARE

2 Anti-tip brackets

12 #12 x 64 mm pan head screws

4

3

/8"–16 x 95 mm wedge anchors

12 #12 at washers

4 #8–18 x 32 mm truss head screws

4 Nylon Zip-it

®

wall anchors

CAUTION

Always wear safety glasses and use other neces-

sary protective devices or apparel when installing or

working with anchors.

Anchors are not recommended for use in lightweight

masonry material such as block or brick, or for use in

new concrete which has not had sufficient time to cure.

The use of core drills is not recommended to drill holes

for the anchors.

Loading...

Loading...