(LV)

(

h

)

(

i

)

A

(

a

) (

c

) (

d

) (

f

)

(

g

)

(

g

)

(

g

)

(

b

)

Fig.15 Completion of assembly

Fig.16-1 Preparation for mounting

Fig.17 Removal

Fig.16-2 Mounting

Thrust washer

Locking bolt

Shrink disc

Thrust washer

Locking bolt

Shrink disc

* Thrust washer

Jig fixing bolt

Continuous-thread bolt

Nut

* Jig fixing bolt

* Adjust bolt

* Hexagon head bolt

Locking bolt

Shrink disc

Hollow shaft

Driven shaft

Hollow shaft

Driven shaft

Hollow shaft

O-ring

Outer diameter

(e)

11

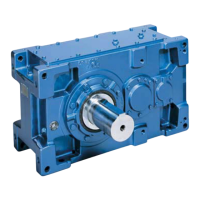

5-2) Hollow shaft

COMMON

5-2-1) Shrink disc type

The shrink disc has a keyless shrink fit mechanism which

shrinks the hollow shaft of a reducer mechanically through

the tightening locking bolt, and holds the driven shaft and

the hollow shaft as one fixture.

Preparation for mounting (Fig.16-1)

(1) Thoroughly degrease contact surface (a), (b), (c), and (d) between the inner diameter of the hollow shaft of the

reducer and the outer diameter of the driven shaft.

(2) Make sure that molybdenum disulfide grease has been smeared on the outer diameter (e) of the hollow shaft,

the inner diameter (f) of the shrink disc, the locking bolts and the surface (g) that the bolts contact. If the amount is too

small, add more.

(3) Smear molybdenum disulfide grease on surface (a) of the outer diameter of the driven shaft. Use "Molykote 321"

or equivalent for molybdenum disulfide grease. Do not smear grease on contact surface (b) and (d) between the inner

diameter of the hollow shaft and the outer diameter of the driven shaft.

Mounting procedure (Fig.16-2)

(1) Insert an O-ring. (Only size 9090 to 9115)

(2) Mount the reducer on the driven shaft and screw nut until faces (h) and (i) make contact.

(3) Set the shrink disc at dimensions LV from the end face of the hollow shaft (Refer to Table 12 on Page 13).

(4) Tighten the locking bolts. Make sure that the surfaces of both plates of the shrink disc are parallel when tightening

bolts. A short-handled spanner is suitable for tightening these bolts. After confirming that the shrink disc is set

correctly, tighten the bolts with a wrench. Uniformly, tighten the locking bolts clockwise (not diagonally) while

keeping both plates parallel. It is recommended to tighten respective bolts by 30 degres each time. Use a torque

wrench to check the tightening torque of all the locking bolts.

Finally, make sure that the plates of the shrink disc are parallel.

Note 1. Tighten the locking bolts at the specified torque (Refer to TA: Table 12 on Page 13).

Note 2. For a vertical reducer, mount a thrust washer to prevent the reducer from moving when locking nut is

loosened. (Fig.15)

Note 3. A high-tension bolt (JIS strength classification: 10.9 or 12.9) is used as a locking bolt. When replacing it,

use one of bolt specified by the manufacturer.

Removal procedure (Fig.17)

(1) Remove by following the above steps in reverse order.

Loosen the locking bolts a little each time so that the plates of the shrink disc do not tilt. If both plates tilt,

do not remove the locking bolts. The both plates may suddenly fly out of the reducer and cause injury.

In such a situation, loosen all of the locking bolts a little and insert a wedge (prepared by customer) into both

plates so that they become parallel.

(2) Set a thrust washer and hexagon head bolt. Remove the reducer from the driven shaft using adjust bolt.

(Note) The mounting/removal jig (parts with * in section A of Fig.17) is optional. Order them as necessary.

Loading...

Loading...