27

(2) Recommended grease

Table 27 Recommended grease

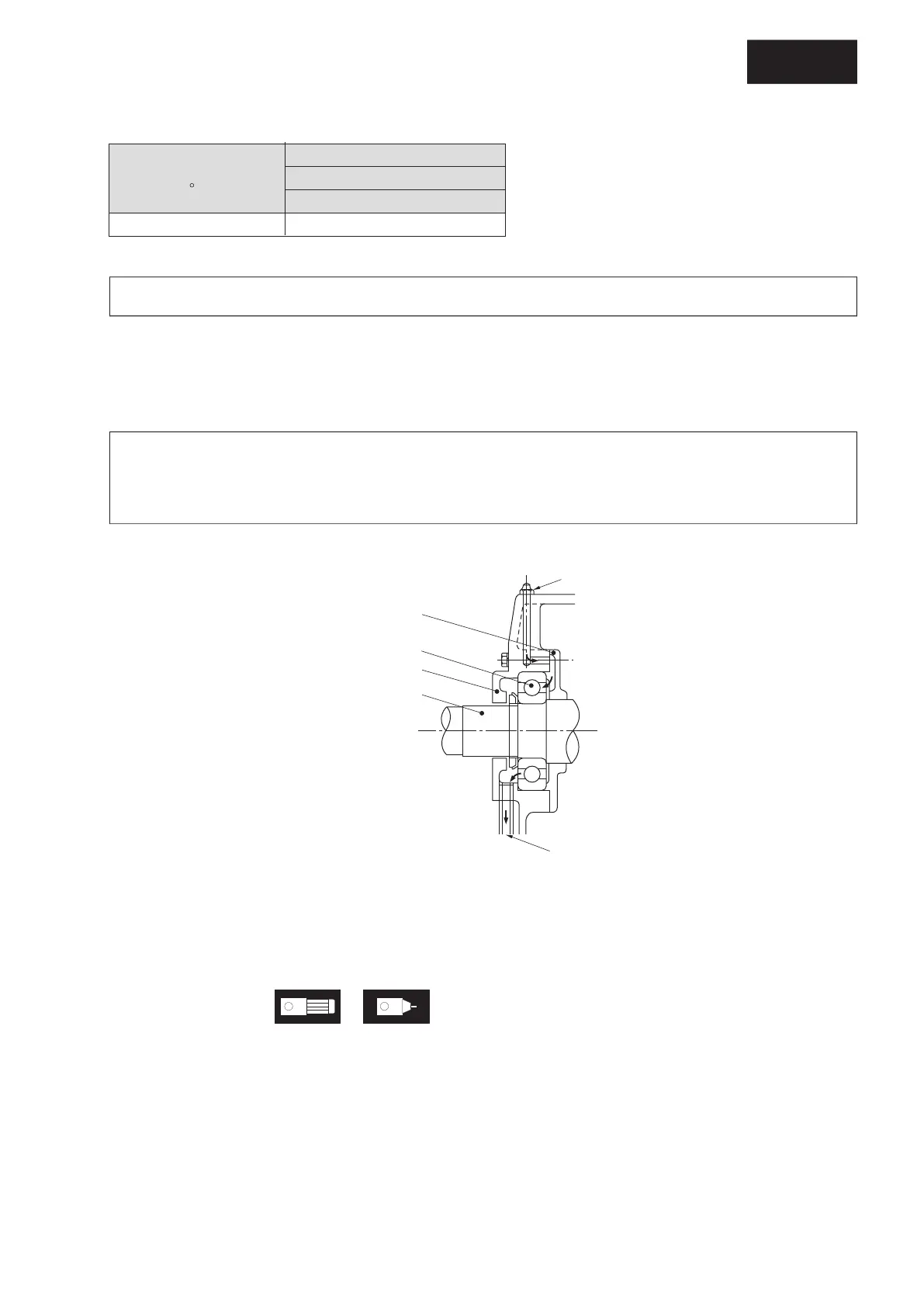

(3) Grease maintenance procedure (refer to Fig.35 and Fig.41 on page 33)

1. Drain used grease from drain plug and replenish new grease from grease nipple during operation.

(Replenishing during non-operation may cause insufficient replenishing amount of grease)

2. After supplying grease, operate it for 10 min and then tighten the plug of drain port.

Fig.35 Construction of open bearing

8-5) Parts Maintenance

To increase operational life, replace the items below every 3 to 5 years.

Exchange parts

•

Bearing, oil seal, nilos, collar, key, shim, packing, stopper, and visible gauge.

•

Check and replace shaft and gear if there are damaged.

Paramax reducer should be returned to the factory to exchange the parts. Please inform the model, ratio, serial

number, and quantity.

Ambient temperature

C

-10 to 40

Open bearing

Tharmal Class 155(F)

Shell oil

Shell Stamina Grease RL2

•

Use only greases listed in table 27.

•

Fill with indicated amount of grease only; otherwise, over heating and grease leakage may result.

•

•

Do not forget to replenish at start-up and periodically during operation; otherwise, abnormal abrasion, noise

and overheating may result.

COMMON

Bracket

Motor shaft

Open bearing

Bearing cover

Outlet

Grease nipples

Exceeding the recommended amount of grease does not extend the replenishment interval.

Loading...

Loading...