-8-

Installing the Vent

Piping

Location

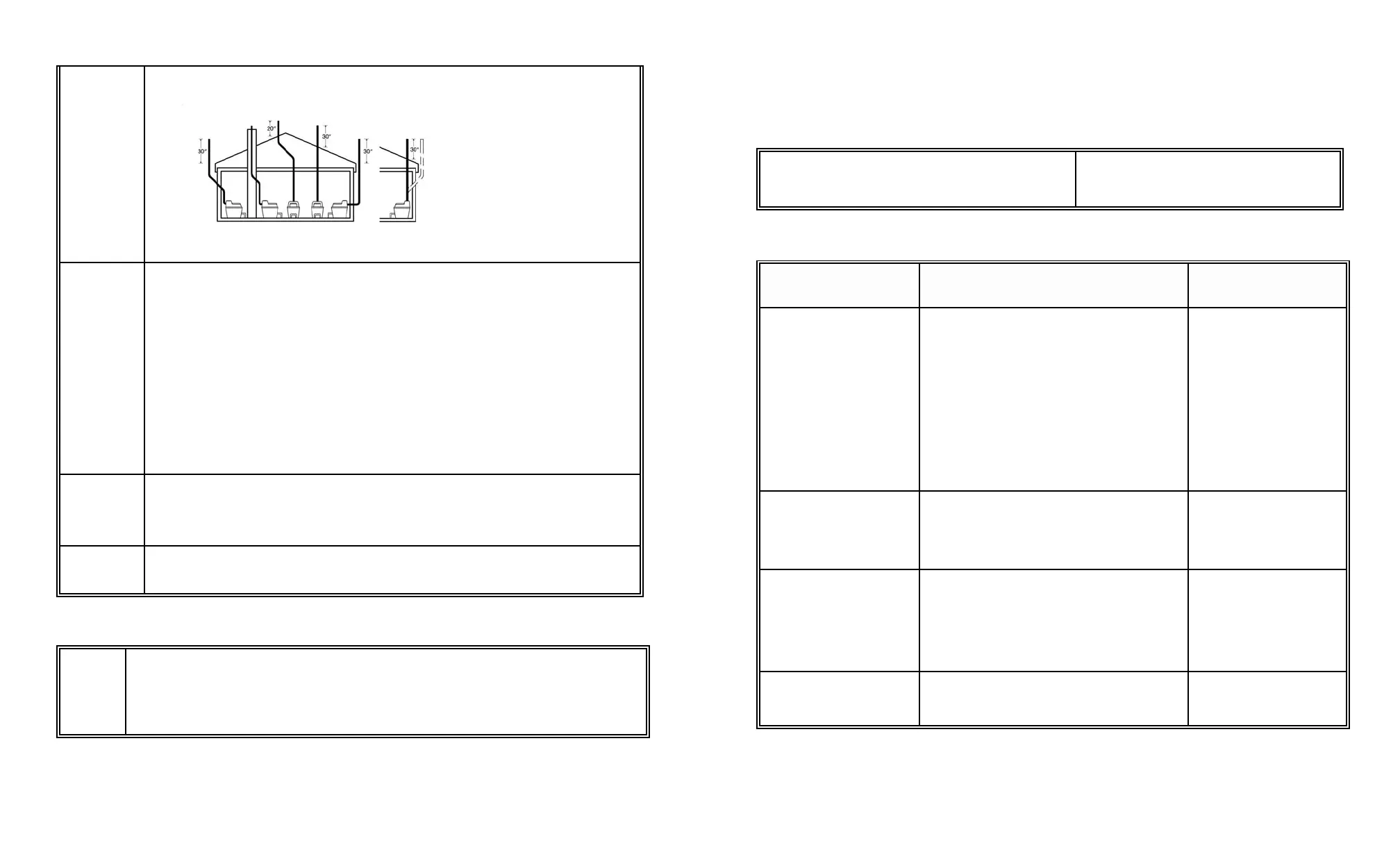

Piping can be installed up the inside wall; through the wall and up the outside wall; or up inside the

wall. The choice depends on ease of installation, visibility, and, (especially if the toilet is to be used

consistently through a cold winter), the need to keep all exposed vent piping insulated

Vent on right is a 4"

non-electric vent. All

others show possible

2" EXCEL vent

configurations.

Piping

Install-

ation

2" pipe and fittings are of standard 2" PVC central vacuum tubing. Additional pipe or fittings are easily

available should you need them. The 4" vent is PVC sewer pipe.

Because each installation is different we make the following general recommendations:-

i) Erect the 4" vent as near to vertical as possible

ii) For the 2" stack, minimise the number of sharp angles because each reduces vent efficiency. Do

not use more than 3 90 degree elbows, and try and use 45 degree elbows wherever possible.

iii) Do not lead the vent pipe downwards at any point because this may lead to the vent pipe being

blocked by condensate.

iv) Use a soft sealant for the connection of the 2" vent stack to the toilet because at some time the

toilet may have to be moved or you may have to access the fan. Also remember that if you are

installing the 12 Volt fan in the 4" vent, or may in the future, you will need to insert it or remove

the 10" section of pipe containing the fan.

v) All exposed 2" vent piping should be insulated with the foam insulation supplied with the

toilet to minimise condensation (especially if winter operation is contemplated). It may also be

useful in some situations to insulate the 4" vent.

Leading

the vent

through

the roof

As shown in the above illustration, the vent stacks should end 2 feet or more above the roof line so that

it is less subject to air turbulence and down draught. Where the piping is taken through the roof, the

roof flashings provided may be used to seal the installation. Where a new roof is being installed, the

roof flashings should be laid underneath the new roofing material.

The

Diffusor

The diffusors provided with the unit are simple devices to be installed at the top of the vent stack. The

diffusor design encourages updraught, and discourages wind and weather from going down the vent

stack. Unlike wind turbines, diffusors do not tend to freeze up in winter.

The Overflow Drain

Access

Port

The 1" overflow drains at the rear of the "EXCEL", exit to both left and right.. If the unit is not always going

to be used in the 110 volt mode, the hose provided should be connected to either the left or right exit of the

drain, and be led to away below the level of the drain to an approved facility. The unused exit of the drain

should be capped. (Hose, hose clamp, and cap are all included with the unit).

If the unit is used in the 110 volt mode, the drain if connected offers protection against heavy loading, or

prolonged electrical outage or failure.

-13-

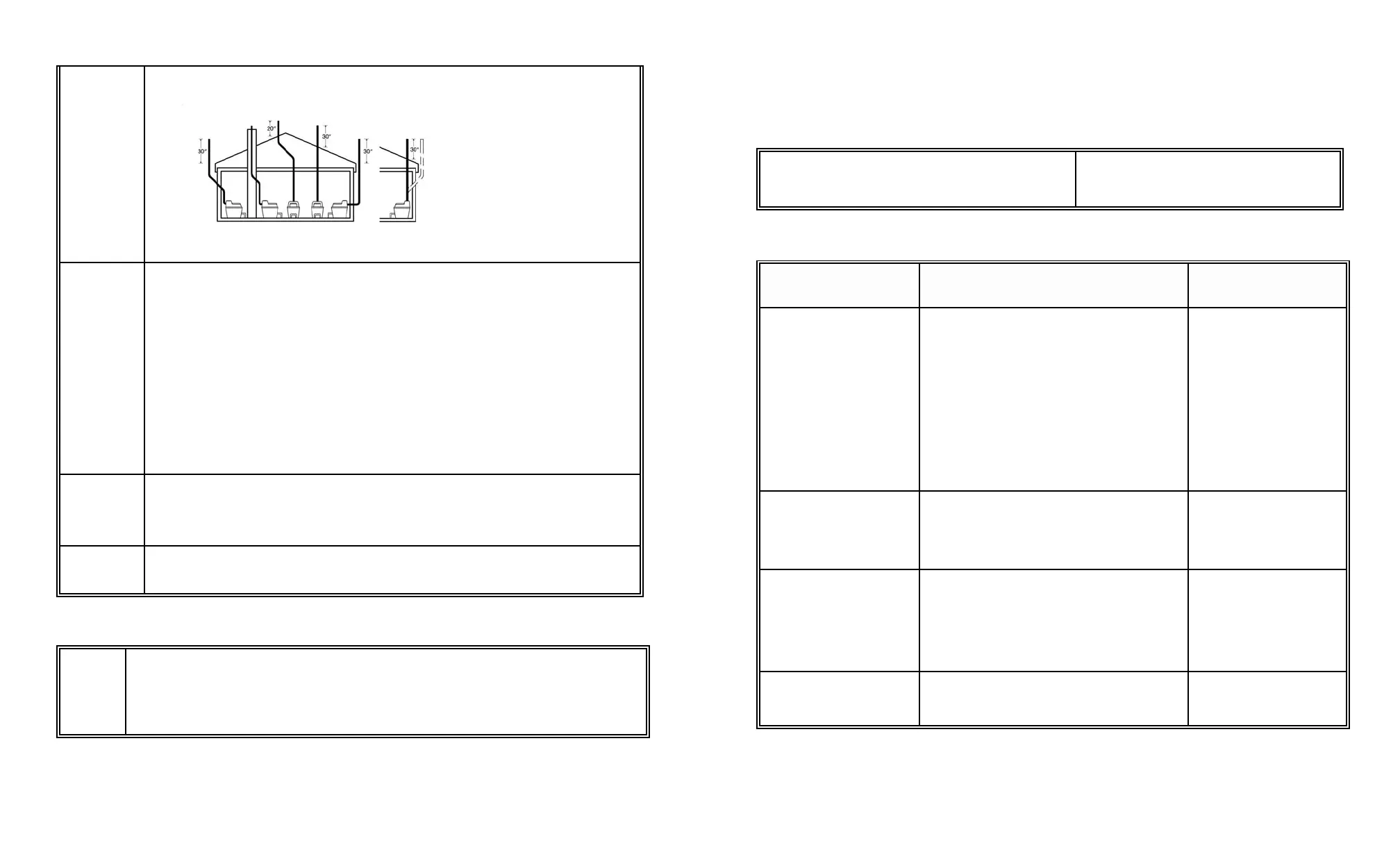

TROUBLE SHOOTING YOUR COMPOST

Characteristics of a Bad Compost

If your compost is over 8 weeks old and it exhibits one or more of the following characteristics, then

it is'bad'.

Extraction Required Too Often

No Obvious Decomposition

Compost is Lumpy

Compost Muddy or Claylike

Flies Present

Compost has Unpleasant Smell

Improving a Bad Compost

Possible Reasons for

Bad Compost

Required Action

Why?

Too much kitchen/

garden waste added

Insufficient microbes

Too frequent mixing

Insufficient peat moss

Too wet

Too Dry

Insufficient mixing

1 Follow "ANNUAL START UP

PROCEDURE"

then:

2 Carry out "ONGOING TOILET

MAINTENANCE"

(If flies present, the compost is probably

dry. Sprinkle diatomaceous earth both on

compost and outside Bio-drum when

mixing compost. Repeat to catch complete

cycle until flies are gone)

Reverting to “Annual

Start Up” procedure

will provide enough

drum space to improve

the compost.

A good compost is

usually not attractive

to flies.

Strong Antibiotics,

or cleaning

chemicals have got

into the compost.

1 Extract all compost

2 Wash out Bio-drum

3 Begin "INITIAL SYSTEM START

UP."

Compost was dead and

has to be restarted

Capacity Exceeded

1 Reduce usage down to maximum

capacity if possible

2 Follow "ANNUAL START UP",

and then "ONGOING TOILET

MAINTENANCE" procedures.

A SUN-MAR can only

operate beyond rated

capacity for a short

time, and then only

once a good compost

has been established

Mechanical problems

with heating or vent

systems.

See instructions for "MECHANICAL

TROUBLE SHOOTING."

Loading...

Loading...