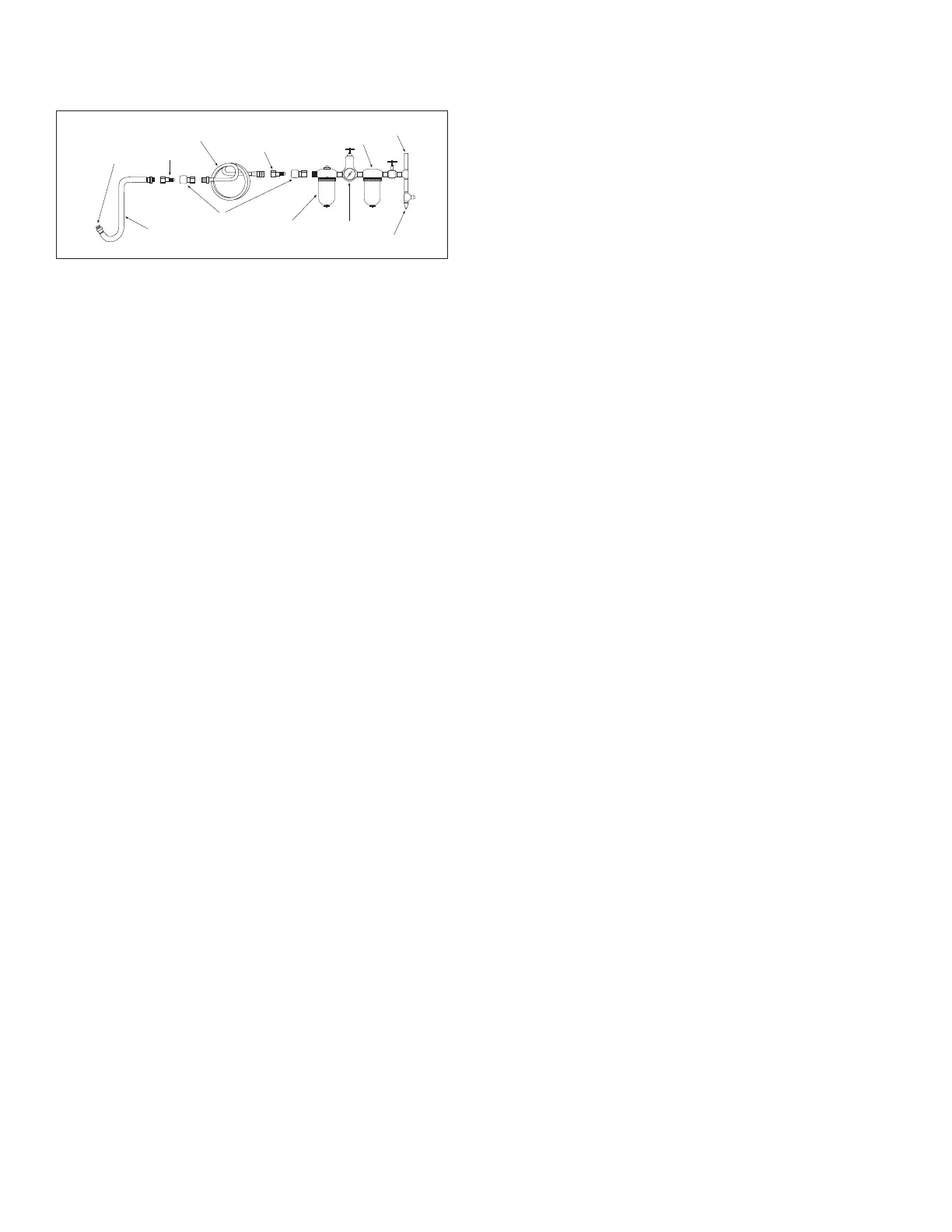

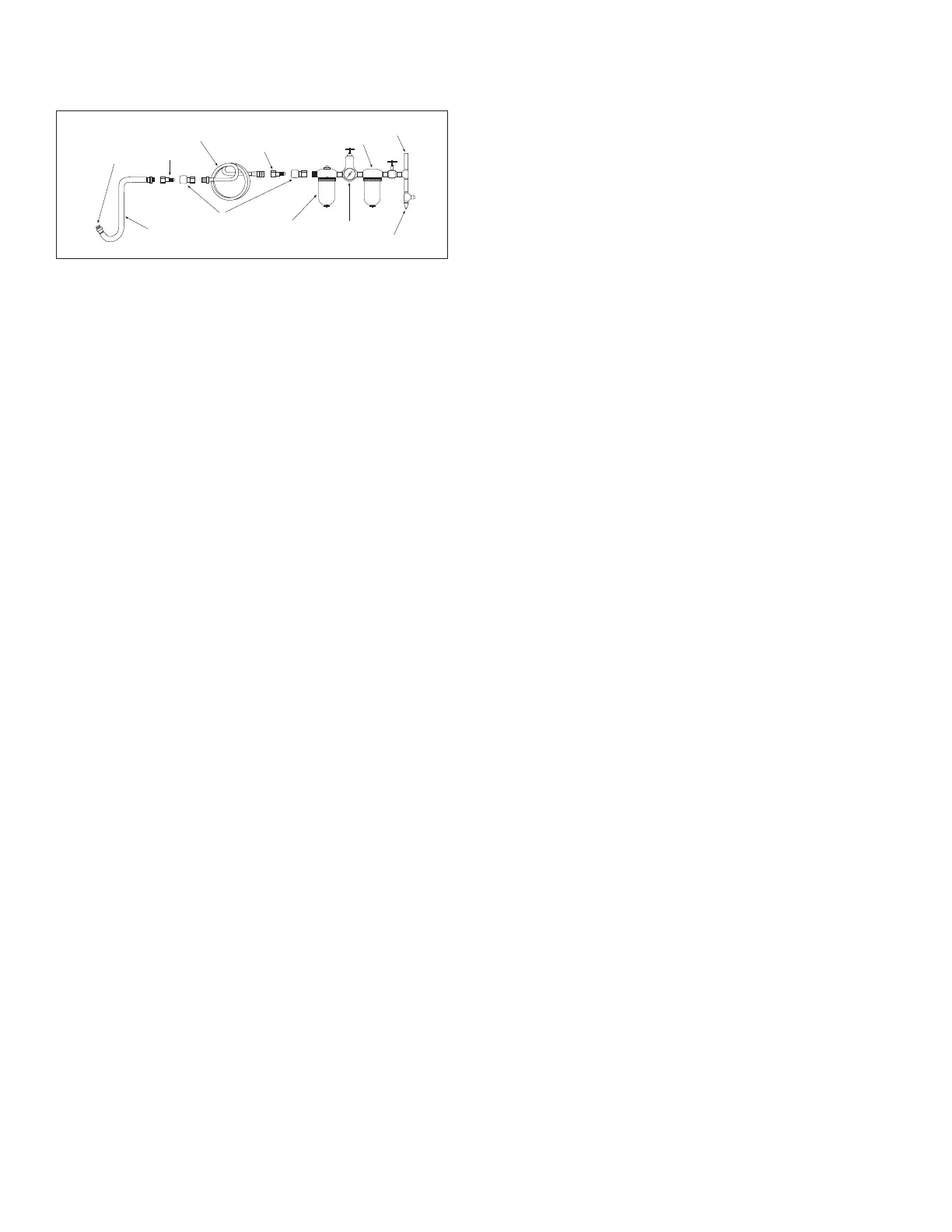

Air Supply...

Tools of this class operate on a wide range of air pressures. It is

recommended that air pressure of these tools measures 90 PSI at

the tool while running free. Higher pressure (over 90 psig; 6.2

bar) raises performance beyond the rated capacity of the tool,

which will shorten tool life because of faster wear and could

cause injury.

Always use clean, dry air. Dust, corrosive fumes and/or water in

the air line will cause damage to the tool. Drain the air tank

daily. Clean the air inlet filter screen on at least a weekly

schedule. The recommended hookup procedure can be viewed in

the above figure.

The air inlet used for connecting air supply has standard 1/4"

NPT. Line pressure should be increased to compensate for

unusually long air hoses (over 25 feet). Minimum hose diameter

should be 3/8" I.D. and fittings should have the same inside

dimensions and be tightly secured.

Operation...

When using the grinder, be careful not to exert excessive force.

Too much force may be hazardous, if it causes the cutting tool

spindle to bend or break.

The burning of the work piece or excessive speed reduction

indicates too much force being applied. Changing to a free

cutting tool may be better for the desired rate of speed and stock

removal.

Avoid hazardous condition by making sure there is sufficient

gripping force on the spindle of the cutting tool by placing the

spindle 7/16” or more inside the collet.

Lubrication...

Lubricate the air motor daily with quality air tool oil. If no air line

oiler is used, run a teaspoon of oil through the tool. The oil can

be squirted into the tool air inlet or into the hose at the nearest

connection to the air supply, then run the tool. The amount of oil

to be used is 1 ounce. Overfilling will cause a reduction in the

power of the tool.

Other factors outside the tool may cause loss of power or erratic

action. Reduced compressor output, excessive drain on the air

line, moisture or restrictions in air pipes or the use of hose

connections of improper size or poor condition may reduce air

supply. Grit or gum deposits in the tool may cut power and may

be corrected by cleaning the air strainer and flushing out the tool

with gum solvent oil or an equal mixture of SAE #10 oil and

kerosene. If outside conditions are in order, and the tool

continues erratic action on low power, disconnect tool from hose

and contact your nearest authorized service center.

Loading...

Loading...