SUNPOWERCORPORATION

SafetyandInstallationInstructions‐Document001‐14158RevAI

©2021SunPowerCorporation.Allrightsreserved.Specificationsincludedintheseinstructionsaresubjecttochangewithoutnotice.Page|4

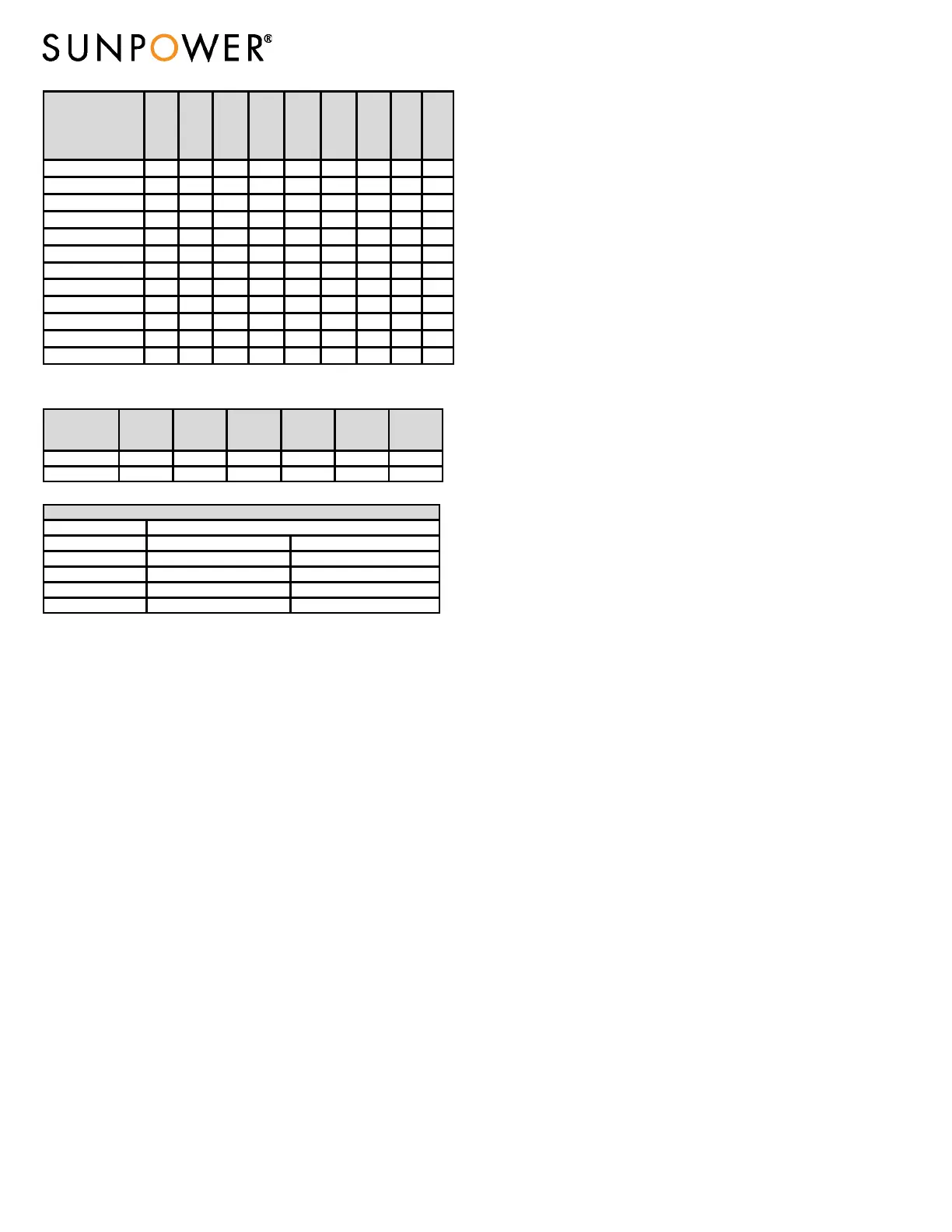

Module

Rated

Power

(W)

+5/‐0%

Voltage

atRated

Power

Vmpp

(V)

Current

atRated

Power,

Impp(A)

Open

Circuit

Voltage

Voc(V)

+/‐3%

Short

Circuit

Current,

Isc(A)

+/‐3%

Current

Temp.

Coeff.

%/°C

Voltage

Temp.

Coeff.

%/°C

Power

Temp.

Coeff.

%/°C

System

Safety

Class

SPR‐M480‐COM 480 44.2 10.87 52.6 11.58 0.060 ‐0.239 ‐0.30 II

SPR‐M475‐COM 475 43.9 10.82 52.6 11.57 0.060 ‐0.239 ‐0.30 II

SPR‐M470‐COM 470 43.7 10.76 52.5 11.56 0.060

‐0.239 ‐0.30 II

SPR‐M465‐COM 465 43.5 10.70 52.5 11.55 0.060 ‐0.239 ‐0.30 II

SPR‐M460‐COM 460 43.2 10.64 52.5 11.54 0.060 ‐0.239 ‐0.30 II

SPR‐M450‐COM 450 42.8 10.52 52.4 11.51 0.060 ‐0.239 ‐0.30 II

SPR‐M480‐COM‐MLSD 480 44.2 10.87 52.6 11.58 0.060 ‐0.239 ‐0.30 II

SPR‐M475‐COM‐MLSD 475 43.9 10.82 52.6 11.57 0.060 ‐0.239 ‐0.30 II

SPR‐M470‐COM‐MLSD 470 43.7 10.76 52.5 11.56 0.060 ‐0.239 ‐0.30 II

SPR‐M465‐COM‐MLSD 465 43.5 10.70 52.5 11.55 0.060 ‐0.239 ‐0.30 II

SPR‐M460‐COM‐MLSD 460 43.2 10.64 52.5 11.54 0.060 ‐0.239 ‐0.30 II

SPR‐M450‐COM‐MLSD 450 42.8 10.52 52.4 1.51 0.060 ‐0.239 ‐0.30 II

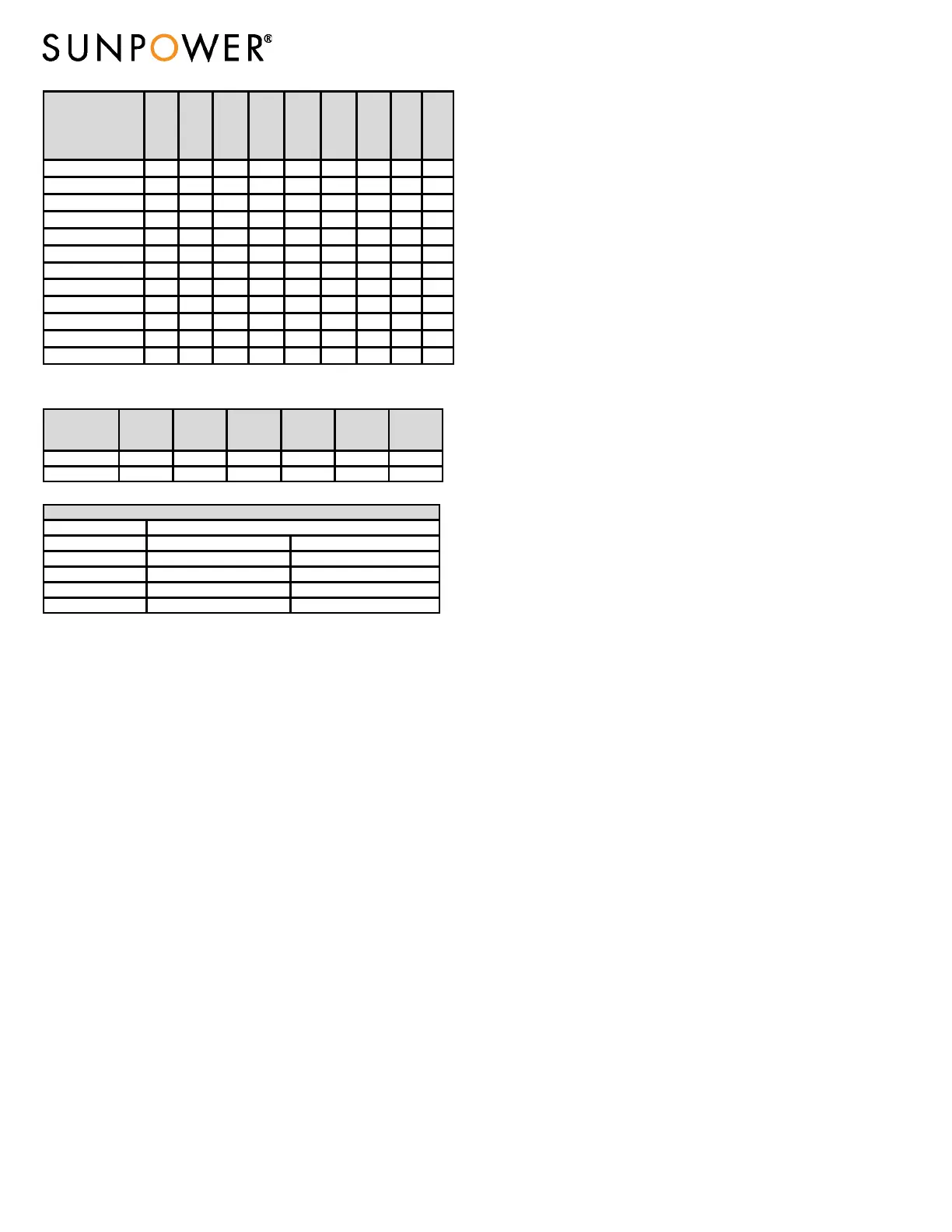

P5 UPP

Module

RatedPower

(W)

Voltageat

RatedPower

Vmpp(V)

Currentat

RatedPower,

Impp(A)

OpenCircuit

VoltageVoc

(V)

ShortCircuit

Current,Isc(A)

Maximum

SystemVoltage

ULVmax(V)

SPR‐P5‐525‐UPP 525 38.3 13.71 46.8 14.77 1500

SPR‐P5‐520‐UPP 520 38.0 13.69 46.6 14.76 1500

Bifaciality(φPmax) 70%+/‐10%

PmaxBiF05

551W 546W

IscBiF05

15.51A 15.50A

PmaxBiF10

578W 572W

IscBiF10

16.25A 16.24A

PmaxBiF20

630W 624W

BifacialCharacteristics

4.0 ElectricalConnectionsandSystemMonitoring

Modulesmaybeconnectedinseriesorparalleltoachievethedesiredelectrical

outputprovidedcertainconditionsaremet.

Evenifallowedbylocalregulation,PlugandSocketconnectorsmatedtogetherin

aPVsystemmustbeofthesametype(model,rating)fromthesame

manufactureri.e.aplugconnector

fromonemanufacturerandasocket

connectorfromanothermanufacturer,orviceversa,shallnotbeusedtomakea

connection.

SunPowerrecommendsaconservativeminimumbendingradius(R)5xcable

diametermustbemaintainedandmustnotbebentonthedirectexitofthe

connectororjunctionbox.

Avoidexposureofelectricalconnectionstodirect

sunlightanddonotplacetheconnectorinalocationwherewatercouldeasily

accumulate.Installersmustrefertoconnectormanufacturer’sinstructionfor

furtherinstallationandconnectionrequirements.

Connectorsarefactoryassembledwithintentionalgapsbetweenthe cabl enut

andthebodyofthe

connector.Donotretightenmoduleconnectornutsasthis

mayleadtostresscrackingoftheconnectorassemblyandwillvoidthewarranty.

4.1EquipmentGrounding

Toreducethepossibilityofelectricalshock,groundtheframeofthemoduleor

arrayperNECbeforewiringthecircuit.Inordertoinstallinaccordancewiththeir

ULListing,SunPowermodulesmustbegroundedusinggroundinghardwarethat

meetsrequirementsforgroundingsystemsinUL467,UL1703,or

UL1741;on

anodizedaluminumframes.SunPowerrecommendsusingoneofthefollowing

methodsofgroundingthemoduleframe.Inaddition,toavoidcorrosiondueto

theuseofdissimilarmetalsSunPowerrecommendsstainlesssteelbetween

copperandaluminum.FortheGeneration5(G5)frame,onlymethods1and2

apply.A‐Series‐BLKmodulesmustbeinstalledwiththeGroundLugAssemblyof

theInvisimountmountingsystemusingtheIlscoGBL‐4DBTgroundinglug

tightenedtoatorqueof85in‐lbstobondthemoduleframetotherail.Therails

usedforbondingmustbepartofthe

system’sgroundpath.

1)Attachalay‐inlug(IlscoGBL‐4DBT,BurndyCL50‐DB‐TorTycoSolklip1954381‐

2)tooneofthegroundingholesonthemoduleframe,andattachthe

groundconductortothelug.Usestainlesssteelhardware(bolt,washers,

andnut).Useanexternal‐

toothstarwasherbetweenthelugandthe

moduleframeinordertopiercetheanodizingandestablishelectrical

contactwiththealuminumframe.Theassemblymustendwithanutthat’s

torquedto20–25in‐lb(fora#10‐32bolt).Alockwasherorotherlocking

mechanismisrequired

tomaintaintensionbetweentheboltandthe

assembly.Theconductormustbeattachedtothegroundlugusingthelug’s

setscrew.RefertoNEC690.

2)SunPowermodulesmayalsobegroundedthroughtheuseofSunPowerIFF

clipswhichareULListed(1703and1741).IFFclip

torquevalueis35–45in‐

lbsfora1/4‐20orM6bolt,butmaybehigherinspecificapplications.

WhenusingIFFclips,themodulemountingsystemmustbegroundedas

perNEC250.

Note:Method3isevaluatedtoUL1703byETL.Assuch,theuseofthese

devices

isnotconsideredpartoftheULListingofthesemodules.

3)IftheUniracSOLARMOUNTsystem isusedformountingthemodules,

groundingisachievedusingeitheraBURNDYWileyWEEB‐UMCorWEEB‐

UGC‐1groundingclipincombinationwithUnirac’sMidorEndclampsand

1/4‐

20boltandflangednut,torquedto120in‐lbs.IftheSOLARMOUNT‐I

systemisusedgroundingisachievedwiththeUniracUGC‐2groundingclips

incombinationwithUnirac’sMidorEndclampsandSliderswitha1/4‐20

boltandflangednuttorquedto120in‐lbs

Note:

Method4wasevaluatedtoUL2703byTUV.Assuch,theuseofthese

devicesisnotconsideredpartoftheULListingofthesemodules.

4)SunPowermodulesmayalsobegroundedusingaWEEB‐9.5NLgroundclipin

betweenthemoduleandsupportingstructure.Thiscombinationis

secured

witha1/4″stainlesssteelrivetora1/4‐20by3/4″zinc‐platedboltwith

zinc‐platedK‐nuttorquedtomin.6ft‐lbstosecurethemoduletominimum

12ga.G90coatedsteelorZ‐purlin,eitherpaintedorunpainted.TheWEEB‐

9.5NLisforsingle

useonly.

5)Othergroundingmethodsmaybeusedinconjunctionwithamodulemounting

systemtestedtoUL2703.Fortheseinstallations,theSunPowermoduleand

framestylemustbetestedandpartoftheinstructionsforthelisted

mountingproduct.TheSunPowermodulemustbeinstalledinaccordance

with

theseinstructionsaswellasthemountingsystem’slistedinstructions.

6)SunPowerG5‐framemodulesmaybegroundedthroughtheuseofan

InvisiMountmidclampthatbondsthemoduleframetotheInvisiMount

rail.InvisiMountrailsectionsmustbebondedandconnectedtoa

groundingconductorusingmethodsandmaterials

specifiedinthe

InvisiMountmanual.

Whenusingmethods2,3,4,5or6themodulemountingstructuremustbe

groundedasperNEC250.Toensuresystemsafetyandstructuralintegrity,strict

adherencetoapplication‐specificSunPowerdocumentationisrequired.

4.2SystemGrounding

ReviewTable2belowforthepropergrounding techniquesfortheinstallationof

yourparticularSunPowermodules.

4.3SeriesConnection

Themodulesmaybewiredinseriestoproducethedesiredvoltageoutput.Do

notexceedthemaximumsystemvoltageshowninmoduledatasheetsand

productlabel.

4.4ParallelConnection

Themodulesmaybecombinedinparalleltoproducethedesiredcurrentoutput.

Eachseriesstringormodulemayberequiredtobefusedpriortocombiningwith

otherstringsiftheresultingmaximumfusesizeallowed(numberofmodules

whichcanbeconnectedinparallelandprotectedbyonefuse)

exceedsthefuse

ratingasshowninthemoduledatasheetandproductlabel.Pleaserefertothe

NECArticle690foradditionalfusingrequirements.

Loading...

Loading...