4

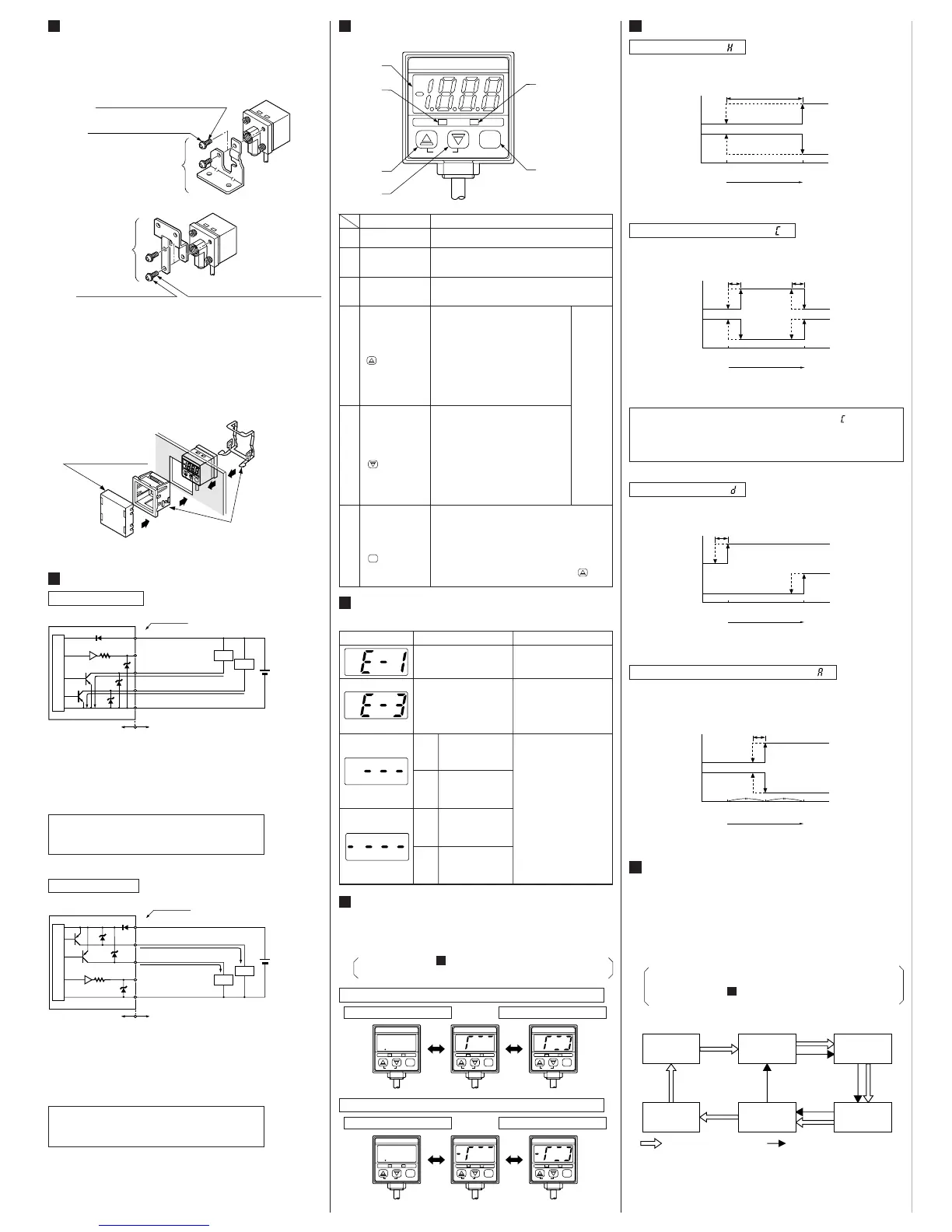

MOUNTING OF STANDARD TYPE SENSOR

䢇 A sensor mounting bracket MS-DPX and MS-DPX-4

(optional) may be used.

When mounting the sensor with the sensor mounting bracket,

etc., the tightening torque should be 1.2N·m or less.

䢇 Panel mounting bracket MS-DPX-2 (optional) and a front

protection cover DPX-04 (optional) are also available.

5

I/O CIRCUIT DIAGRAM

NPN output type

Tr2

Tr1

1kΩ

100mA max.

100mA max.

Users’ circuitInternal circuit

(Blue) 0V

(White) Comparative Output 2

(Black) Comparative Output 1

(Gray) Analog

voltage output

(Brown)

ⳭV

Color code

Load

Load

ZD2

ZD3

ZD1

D

12 to 24V DC

%

Ⳮ

ⳮ

Sensor circuit

Ⳮ10

ⳮ15

(Note)

Sensor mounting bracket

MS-DPX (optional)

M4 (length 6mm) pan head screw

(attached with MS-DPX)

Spring washer

(attached with MS-DPX)

D

P

2

-

2

0

–

1

0

1

.

3

k

P

a

O

U

T

2

O

U

T

1

M

O

D

E

0

-

A

D

J

Panel mounting bracket

MS-DPX-2 (optional)

(Suitable for 1 to 3.2mm thick panel)

D

P

2

-

2

0

–

1

0

1

.

3

k

P

a

O

U

T

2

O

U

T

1

M

O

D

E

0

-

A

D

J

Front protection cover

DPX-04 (optional)

Symbols

…

D: Reverse supply polarity protection diode

Z

D1, ZD2, ZD3: Surge absorption zener diode

Tr

1, Tr2: NPN output transistor

Note: The analog voltage output is not incorporated with a short-circuit

protection circuit. Do not directly connect a power supply or a

capacitive load. When using the analog voltage output, take

care to connect external equipment of proper input impedance.

Also, when a cable extension is used, voltage drop due to cable

resistance should be taken into account.

PNP output type

Users’ circuitInternal circuit

Color code

100mA max.

100mA max.

ZD1

ZD2

ZD3

Tr1

Load

Load

(Brown)ⳭV

(White) Comparative Output 2

(Black) Comparative Output 1

(Gray) Analog

voltage output (Note)

(Blue) 0V

12 to 24V DC

%

Ⳮ

ⳮ

Tr2

D

Sensor circuit

1kΩ

Ⳮ10

ⳮ15

Symbols

…

D: Reverse supply polarity protection diode

Z

D1, ZD2, ZD3: Surge absorption zener diode

Tr

1, Tr2: PNP output transistor

Note: The analog voltage output is not incorporated with a short-circuit

protection circuit. Do not directly connect a power supply or a

capacitive load. When using the analog voltage output, take

care to connect external equipment of proper input impedance.

Also, when a cable extension is used, voltage drop due to cable

resistance should be taken into account.

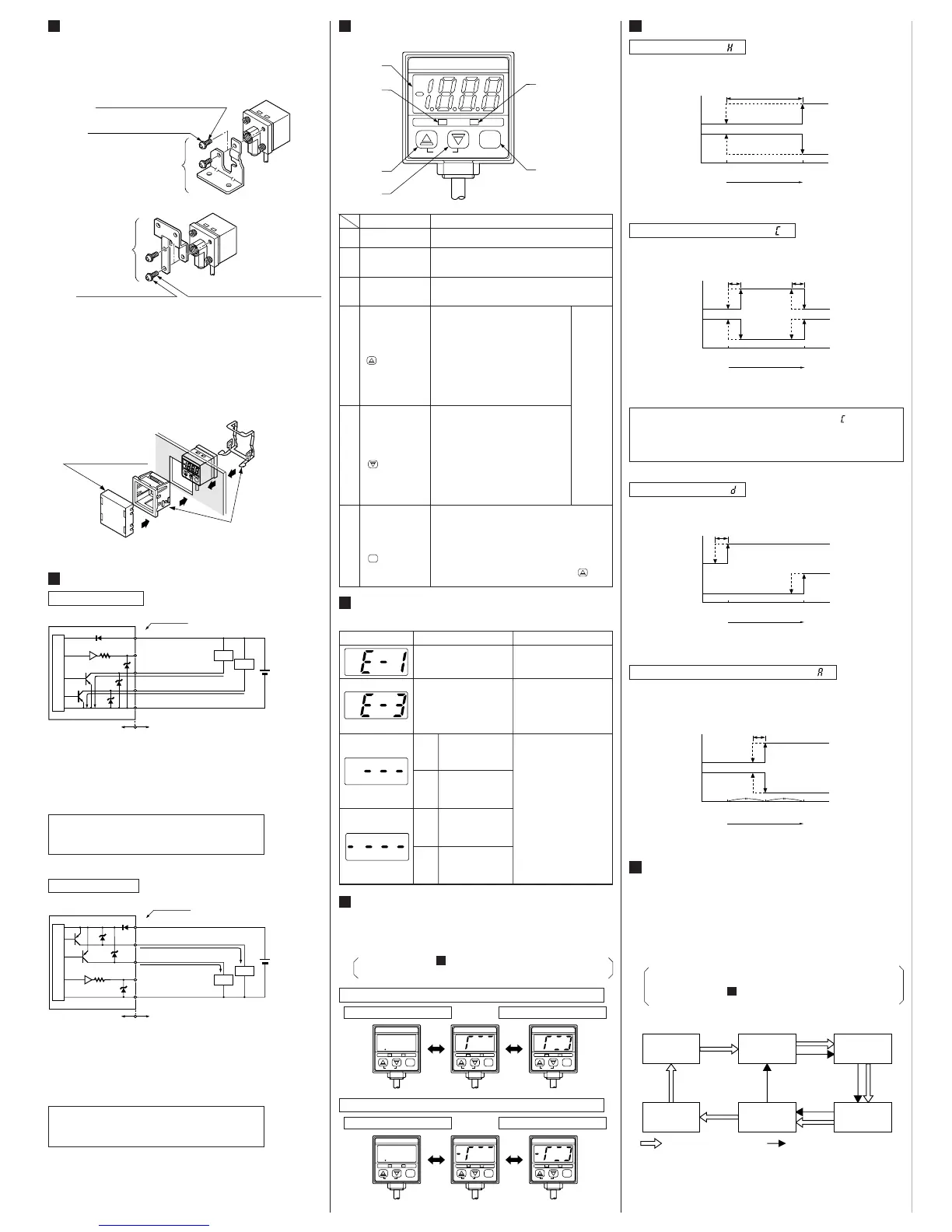

6

FUNCTIONAL DESCRIPTION OF

OPERATION PANEL

DP2-20

–101.3kPa

OUT2OUT1

MODE

0-ADJ

1

2

3

6

4

5

06H0129

Description Function

1

2

3

4

5

6

3

1

/

2

digit LED

display (Red)

Comparative Output 1

operation indicator

(Orange)

Comparative Output 2

operation indicator

(Green)

Increment key

()

Decrement key

()

Mode selection key

()

Displays measured pressure, settings, error mes-

sages and key-protect status.

Lights up when Comparative Output 1 is ON.

Lights up when Comparative Output 2 is ON.

• In the initial setting mode, pressing the

key changes the settable digit.

• In the Set Value 1, 2 modes, pressing

the key changes the set value to the

high pressure side in case of positive

pressure type sensor and to the high

vacuum side in case of vacuum pressure

type sensor.

•

In the sensing mode, if the key is pressed

continuously for 4 sec. or more, the display

shows peak hold value.

• In the initial setting mode, pressing the

key changes the set conditions.

• In the Set Value 1, 2 modes, pressing

the key changes the set value to the

low pressure side in case of positive

pressure type sensor and to the low

vacuum side in case of vacuum pressure

type sensor.

•

In the sensing mode, if the key is pressed

continuously for 4 sec. or more, the display

shows bottom hold value.

• Pressing the key changes the selected mode to

sensing mode, Set Value 1 (P1) set mode and Set

Value 2 (P2) set mode.

• In the sensing mode, if the key is pressed continu-

ously for about 3 sec., key-protect can be

set/released.

• In the sensing mode, if the mode selection key is

pressed while pressing the increment key ( ) , the

initial setting mode is obtained.

In the sensing mode, if both the keys are pressed

simultaneously, zero-point adjustment is done.

7

ERROR MESSAGES

䢇 When an error occurs, take the following corrective action.

Error message Cause Corrective action

Overcurrent due to short-

circuit.

Pressure is being applied

during zero-point adjust-

ment.

Positive

pressure

type

Vacuum

pressure

type

Positive

pressure

type

Vacuum

pressure

type

Applied pressure exceeds

the upper limit of dis-

playable pressure range.

Applied pressure exceeds

the lower limit of display-

able pressure range.

Applied pressure exceeds

the lower limit of display-

able pressure range.

Applied pressure exceeds

the upper limit of dis-

playable pressure range

.

Switch off the power supply

and check the load.

Applied pressure should be

brought within the rated

pressure range.

Applied pressure at the

pressure port should be

brought to atmospheric

pressure and zero-point

adjustment should be done

again.

8

ANALOG BAR DISPLAY

䢇

Pressure changes are displayed in an analog fashion by using LED bars.

Hence, any sudden changes in pressure can be detected at a glance.

䢇

The analog bar display shows the measured pressure, irrespective

of the pressure unit, in steps of 10% F.S. approx.

• Please refer to SETTING

2

Initial setting for the

procedure to change to analog bar display.

11

Analog bar display for positive pressure type sensor

Atm. pressure condition

Atm. pressure condition

High pressure condition

High vacuum condition

DP2-21

100kPa

OUT2OUT1

MODE

0-ADJ

DP2-21

100kPa

OUT2OUT1

MODE

0-ADJ

DP2-21

100kPa

OUT2OUT1

MODE

0-ADJ

06H0132

DP2-20

–101.3kPa

OUT2OUT1

MODE

0-ADJ

DP2-20

–101.3kPa

OUT2OUT1

MODE

0-ADJ

DP2-20

–101.3kPa

OUT2OUT1

MODE

0-ADJ

9

OUTPUT MODES & THEIR CHARACTERISTICS

Hysteresis mode ( )

䢇 The common hysteresis of the comparative outputs can be

set, as desired, with the set values.

Window comparator mode ( )

䢇

The comparative outputs can be turned ON or OFF by a pressure

which is within the pressure range set by Set Value 1 and Set Value 2.

Comparative

Output 1

Comparative

Output 2

ON

OFF

ON

OFF

0

Set Value 1 (P1) Set Value 2 (P2)

High pressure

(Positive pressure type)

High vacuum

(Vacuum pressure type)

Hysteresis

()

Hysteresis: 1 digit or more

2 digits or more when

using psi unit

Comparative

Output 1

Comparative

Output 2

ON

OFF

ON

OFF

0

Set Value 1 (P1)

Set Value 2 (P2)

High pressure

(Positive pressure type)

High vacuum

(Vacuum pressure type)

Hysteresis Hysteresis

Hysteresis: 1 digit

2 digits when

using psi unit

()

Comparative

Output 1

Comparative

Output 2

ON

OFF

ON

OFF

0

Set Value 1 (P1) Set Value 2 (P2)

High pressure

(Positive pressure type)

High vacuum

(Vacuum pressure type)

Hysteresis: 1 digit

2 digits when

using psi unit

Hysteresis

()

Dual output mode ( )

䢇 The outputs can be put to different use such as detection of

different kinds of objects, control function, alarm function etc.

Comparative

Output 1

Comparative

Output 2

ON

OFF

ON

OFF

0

Set Value 1 (P1) Set Value 2 (P2)

Set Value 3 (P3)

High pressure

(Positive pressure type)

High vacuum

(Vacuum pressure type)

Hysteresis

Hysteresis: 1 digit

2 digits when

using psi unit

()

Automatic sensitivity setting mode ( )

䢇 Using actual objects, if the pressure values for OK objects

and NG objects are input, then the sensor is automatically set

to the optimum pressure value (mid-value).

10

PRESSURE UNITS

䢇 The pressure unit can be selected as per customer’s

requirement.

䢇 In case of positive pressure type, the pressure unit can be

changed from International System of Units (SI) ‘kPa’ or

‘MPa’ to ‘kgf/cm

2

’, ‘bar’ or ‘psi’. In case of vacuum pressure

type, the pressure unit can be changed from International

System of Units (SI) ‘kPa’ to ‘kgf/cm

2

’, ‘bar’, ‘psi’, ‘mmHg’ or

‘inHg’.

•

When the pressure unit is changed, the set values and the

measured value are automatically converted.

• Please refer to SETTING

2

Initial setting for the

procedure to change the pressure unit.

11

inHg

kPa (Note)

kgf/cm

2

mmHg psi bar

: Positive pressure type: Vacuum pressure type

International System

of Units (SI)

• When operating in window comparator mode ( ) Set Value

1 (P1) and Set Value 2 (P2) should be set with a difference

of 3 digits or more. However, when the pressure unit is set

to ‘psi’, the difference should be 6 digits or more.

Note: MPa in case of DP2-22䡺, DP2-42䡺 and DP2-62䡺.

Analog bar display for vacuum pressure type sensor

Sensor mounting

bracket

MS-DPX-4 (optional)

M4 (length 6mm) pan head screw

(attached with MS-DPX-4)

Spring washer

(attached with MS-DPX-4)

Note: In case mounting brackets or screws other than the sensor

mounting bracket shown in the fiqure above are used, the length

of the screws inserted into the pressure port attachment should

be 5mm or less. If the length of the screws is longer than 5mm,

the sensor may be damaged.

<MS-DPX-4>

<

MS-DPX>

Loading...

Loading...