~

GENERALINFORMATION

Thisappliance compUeswithNational Safely Stan-

dards and is tested and listed by Underwriters

Laboratories, Inc. to ANSI Z21.50-1986 as a vented

decorative gas appliance.

Installation must conform to local codes. In the

absence of local codes installation must conform

with the current National Fuel Gas Code, ANSI

Z223.1. Theappliance,when installed,must be

electricallygroundedinaccordance withlocalcodes,

withthe National ElectricalCode, ANSIINFPANo.

70-1984.

Note: Installationandrepairshouldbedonebya

qualifiedserviceperson.Theapplianceshouldbe

inspectedannually

byaprofessionalserviceper-

son.Morefrequentinspectionslc/eaningsmaybe

requireddw toexcessive/intfromcarpeting,bed-

dingmaterial,etc.Itis imperativethatthecontrol

compartment,burnersandcirculatingairpassage

waysoftheappliancebekeptclean.

Provide for adequate ventilation.

~

Provide adequate clearances around air openings

and adequate accessibility dearance for service

and proper operation. Never obstruct the front

opening ofthe fireplace.

Minimumclearances to combustibles are:

Sides 112', Floor 0', Back 112', Ceiling 41 112',

Sidewall O', Vent Surfaces 1'.

Minimum inlet gas pressure is 4.5 inches water

column for natural gas and 11 inches water column

propane for the purpose of input adjustment.

Maximuminlet gas supply pressure is 7.0 inches

water column fornatural gas and 13.0 inches water

column forpropane.

Input is 18,000 aTUMR

A 1/8' N.P.T. plugged tapping is provided on the

gas control along side of the outlet to the main

burner for a test gage connection.

This apptiance must oot be connected to a chimney

flue servicing a solid fuel burning appliance.

The appliance must be isolated from the gas supply

piping system by dosing its individual manual shut-

off valve during any pressure testing of the gas

supply piping system altest pressures equal to or

more than 112 psig.

2

INTRODUCTION

The GHC-SOOOis a heat circulating system that

utilizing a miUivok gas control valve and a piezo

ignition system. Glass doors, trim kits and a forced

air fan assembly are optional equipment.

The GRD-SOOO

is a radiant heat system that utiliz-

ing a millivoh gas control valve and a piezo ignition

system. Glass doors are optional equ~ment.

ASSEMBLYSTEPS

1.Position appliance prior to framing or into pre-

pared framing.

2.Route gas line to firebox compartment and install

m~livoh waD switch.

3. Install vent system.

4. Field wire main power supply to appliance junc-

tion box (only if optional fan assembly is to be

installed aI a later time).

5. Complete finished wall malerial and trim.

6. Install controls and burner assembly. Connect to

gas supply.

7. Wife remote millivolt wall switch to control valve.

8. Attach horizontal louvers andlor optional \rim

pieces.

9. Install the optional glass doors.

INSTALLATION

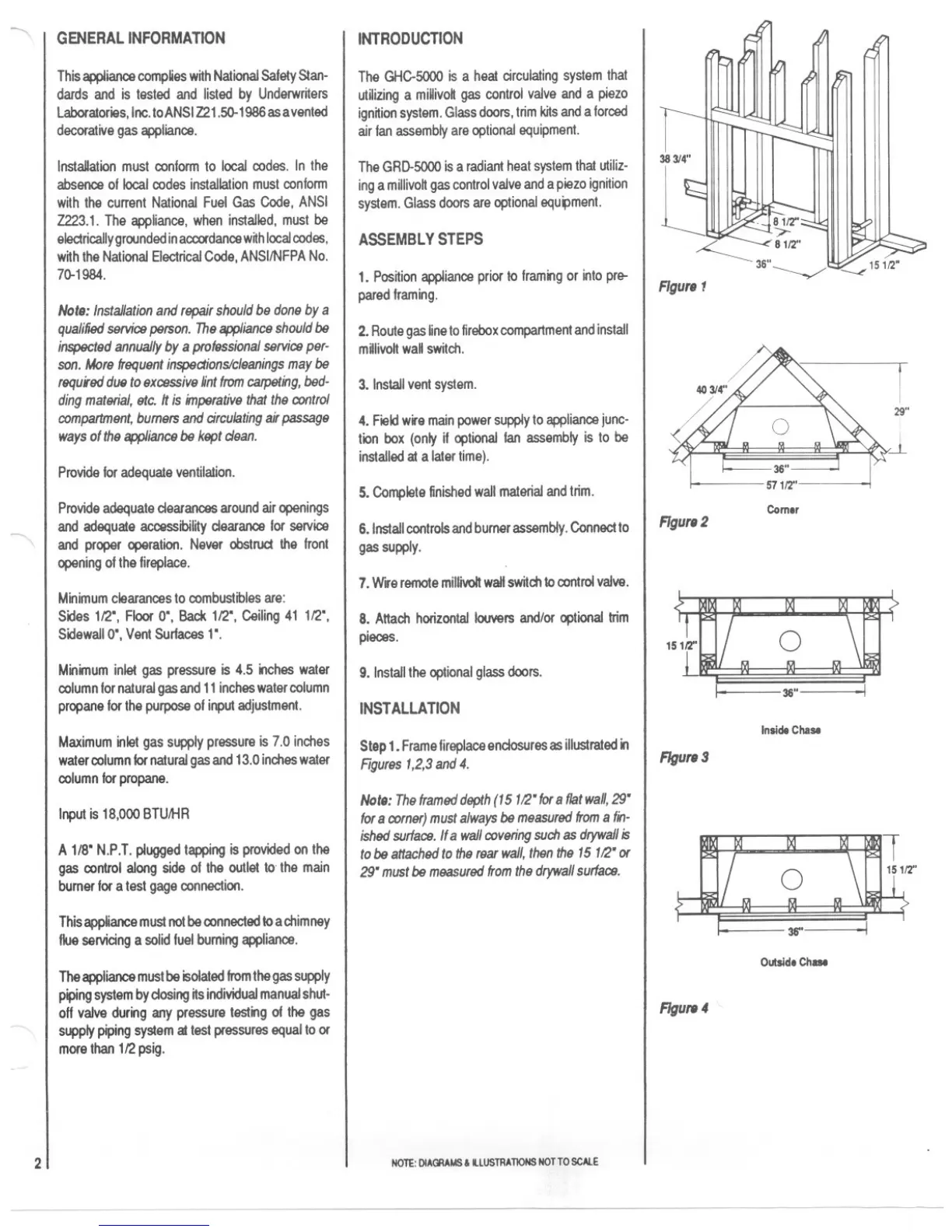

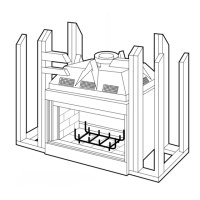

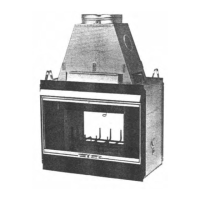

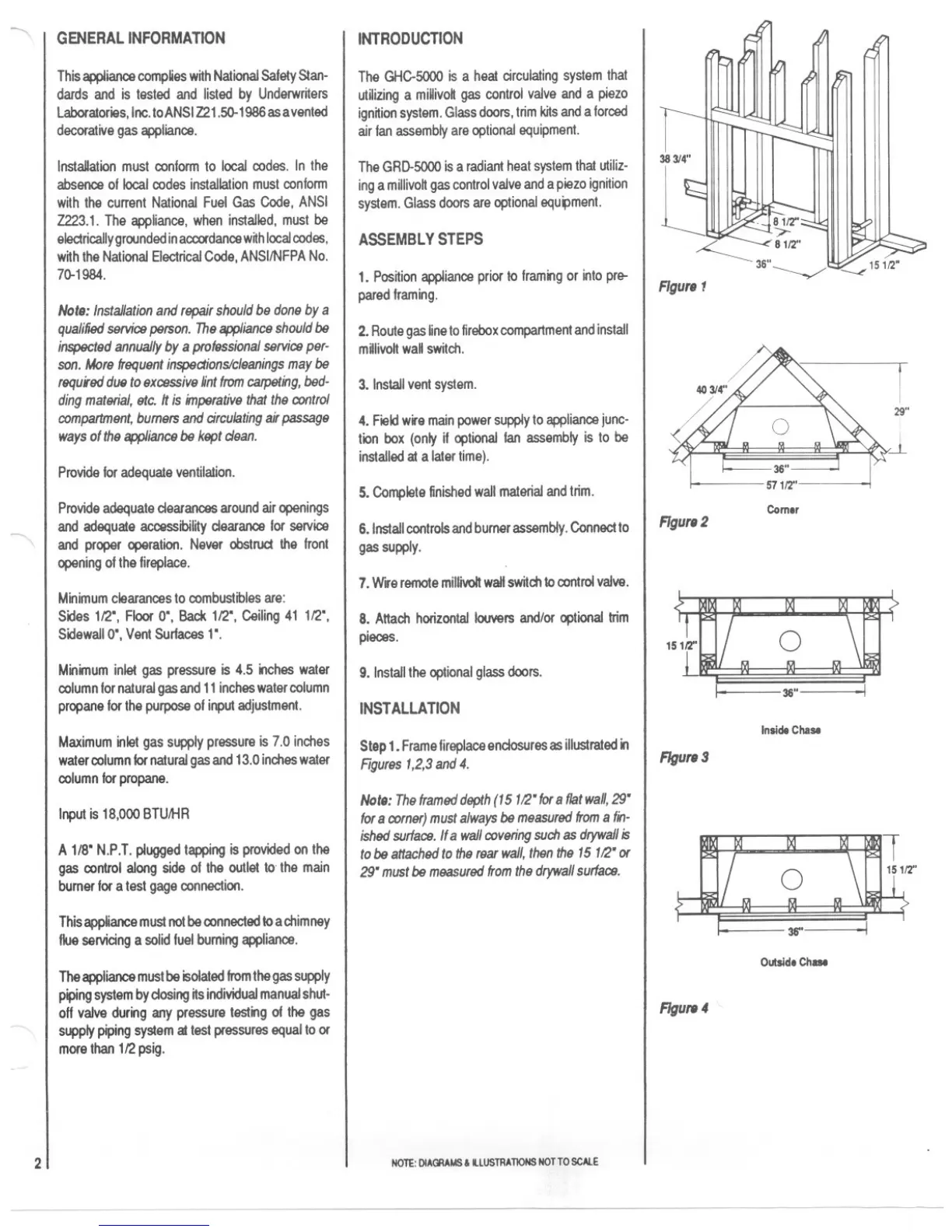

Step1. Frame fireplace endosures as illustrated in

Rgures1,2,3and4.

Note:Theframeddepth(15112"for8flatwall,29"

for8corner)mustalwaysbemeasuredfromafin-

ishedsurface.Ifa wallcoveringsuch

as drywallis

tobeattachedtotherearwall,thenthe15112"or

29"mustbemeasuredfromthedrywallsurface.

NOTE:DIAGRAMS& illUSTRATIONS NOTTO SCAlE

~

r

29"

i

~

Comer

FIgure2

36"

Inside Chase

FIgure 3

mt

36" I

Outside Chase

FIgure4

Loading...

Loading...