55

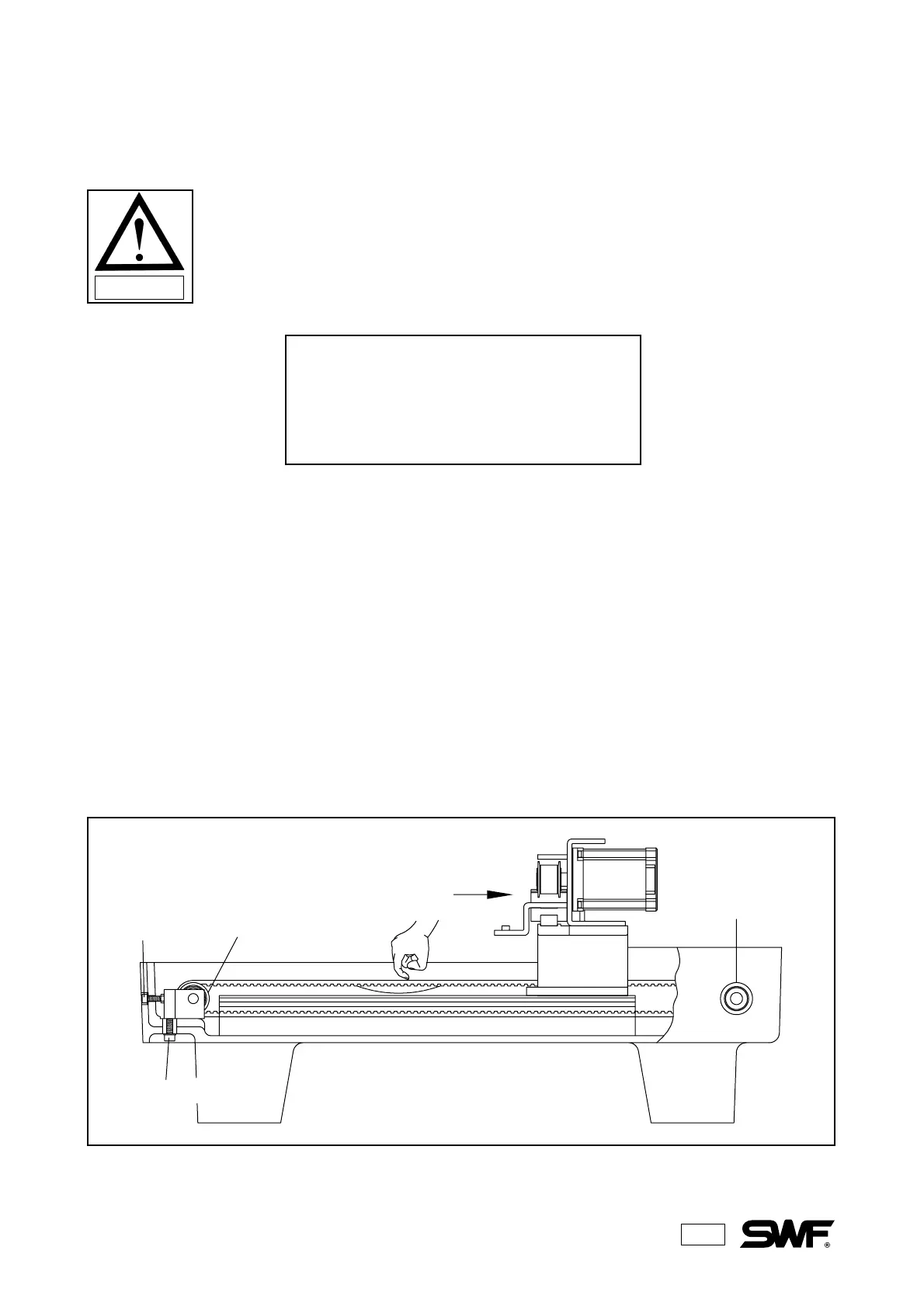

ADJUSTMENT OF DRIVE BELT TENSION

TIMING BELT OF Y-AXIS

Check the belt with a sound wave tension meter. Pluck the end of the X drive at the center of the belt with a

finger or tool and then adjust the Y-axis belt to 30~32 kgf. The input data should be :

Weight : 003.8gf/m

Width : 015.0mm/#R

Span : 0540mm

Release the tension base fixing bolts and turn the tension adjusting bolt to achieve the proper tension.

Turning the bolt clockwise increases the belt tension. Turning it counter-clockwise decreases the tension.

CAUTION

The main power should be off when adjusting drive belt tensions.

When drive belt tension adjustments are needed, contact your service technician

as the loss of tension will adversely affect the quality of embroidery as well as the

operation of the machine.

Tension Adjustment Specifications

Model Name : U-305 Series – Standard

Phonometry Belt Tester

Manufacturer : UNITTA

Tension Base Bolt

Drive Pulley

Driven Pulley

Tension

Adjusting Bolt

X-Drive

Loading...

Loading...