A : Mains Lead

A primary power supply cable is available for this welding equipment. Connect the power supply

cable with required voltage. Check whether the voltage value varies in the given range with a

multi-meter.

B : Connection of Output Cables

Two Dinze sockets are available for this welding equipment. Connect the plug to the socket on

the panel board. It is possibly damaging to both the plug and socket, if the plug and the socket

are incorrectly connected.

The electrode holder cable should be connected to the negative terminal, while the work piece

should be connected to the positive terminal.

•Positive connection electrode holder to “–”,while work piece to “+”

•Negative connection work piece to “–”, while electrode holder to “+”.

It is necessary to increase the diameter of cable in order to maintain and improve the performance

of voltage output.

C : On / O Switch

While the power supply switch is on, the built-in fan works and current meter displays the current

value.

D : Welding Current Output Setting

According to practical demand, set the parameters of current output by the operation of welding

current knob and arc-leading pulse knob.

E : O.C. Light

When the pilot lamp is lit, the machine is in a temporary shut down mode to prevent damage

from over heating. The machine will automatically restart when the internal temperature has

dropped to a safe operational level.

F : TIG / MMA Switch

Select between TIG and MMA welding process.

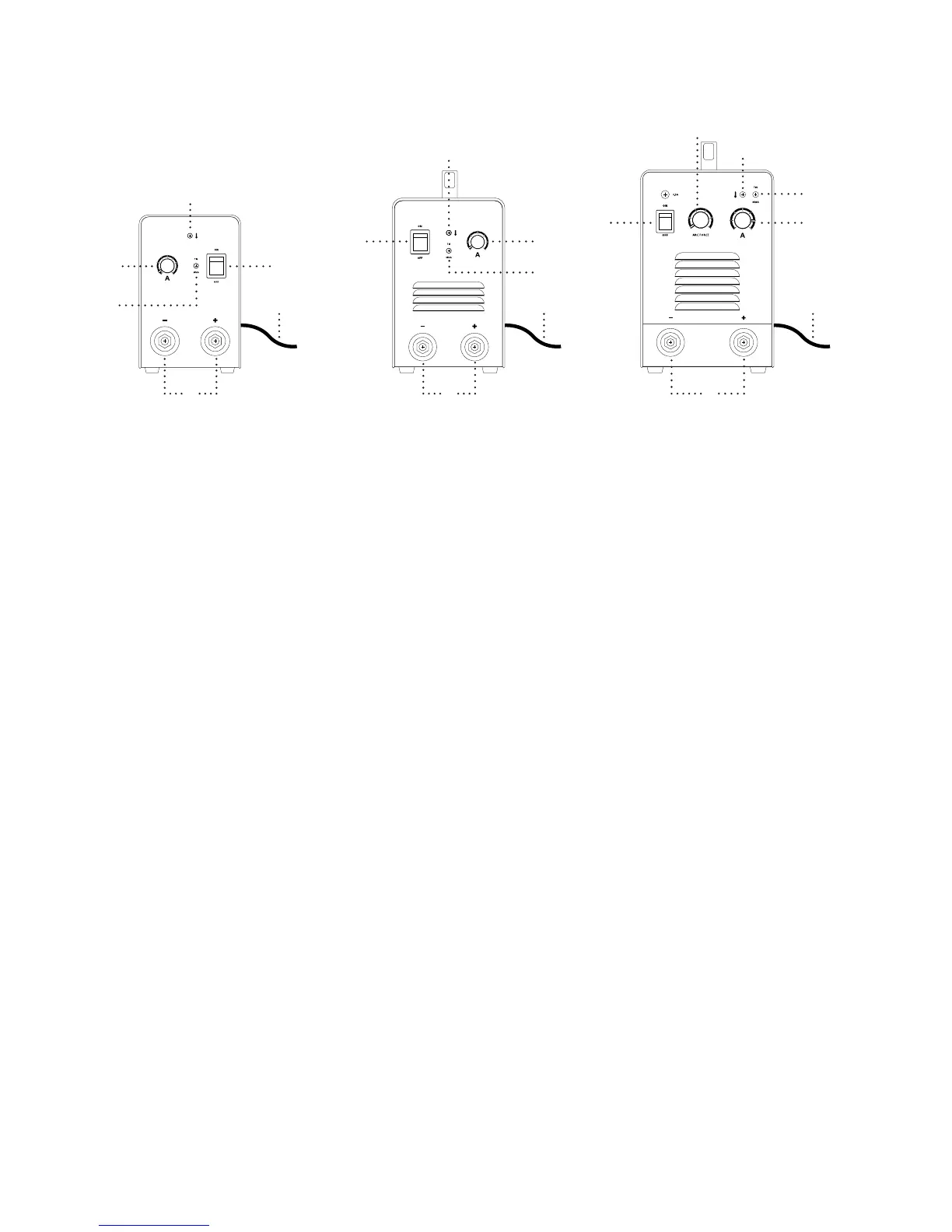

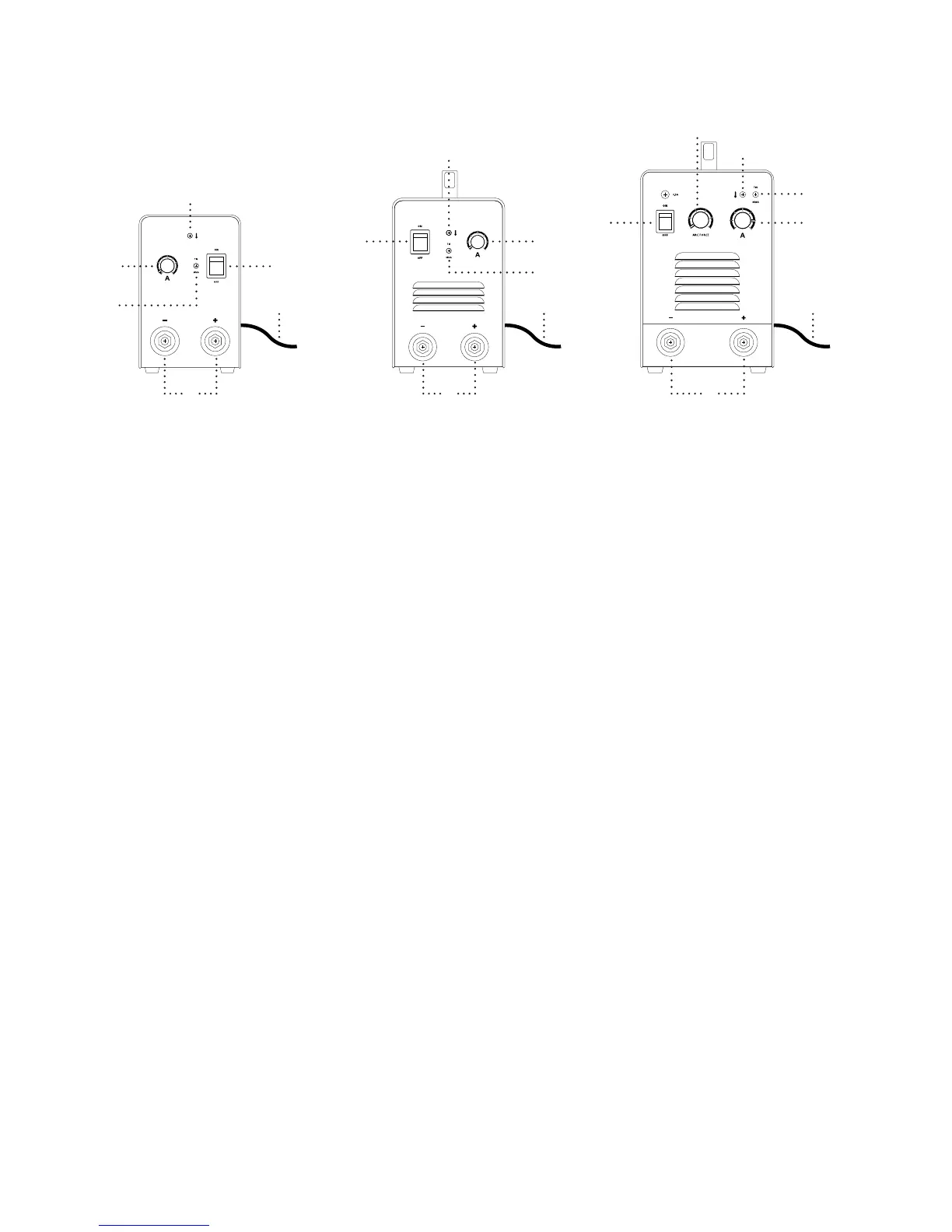

Installation and Operation

A A A

B

C

C

C

B B

D

F

D

E

E

E

G

F

D

F

Loading...

Loading...