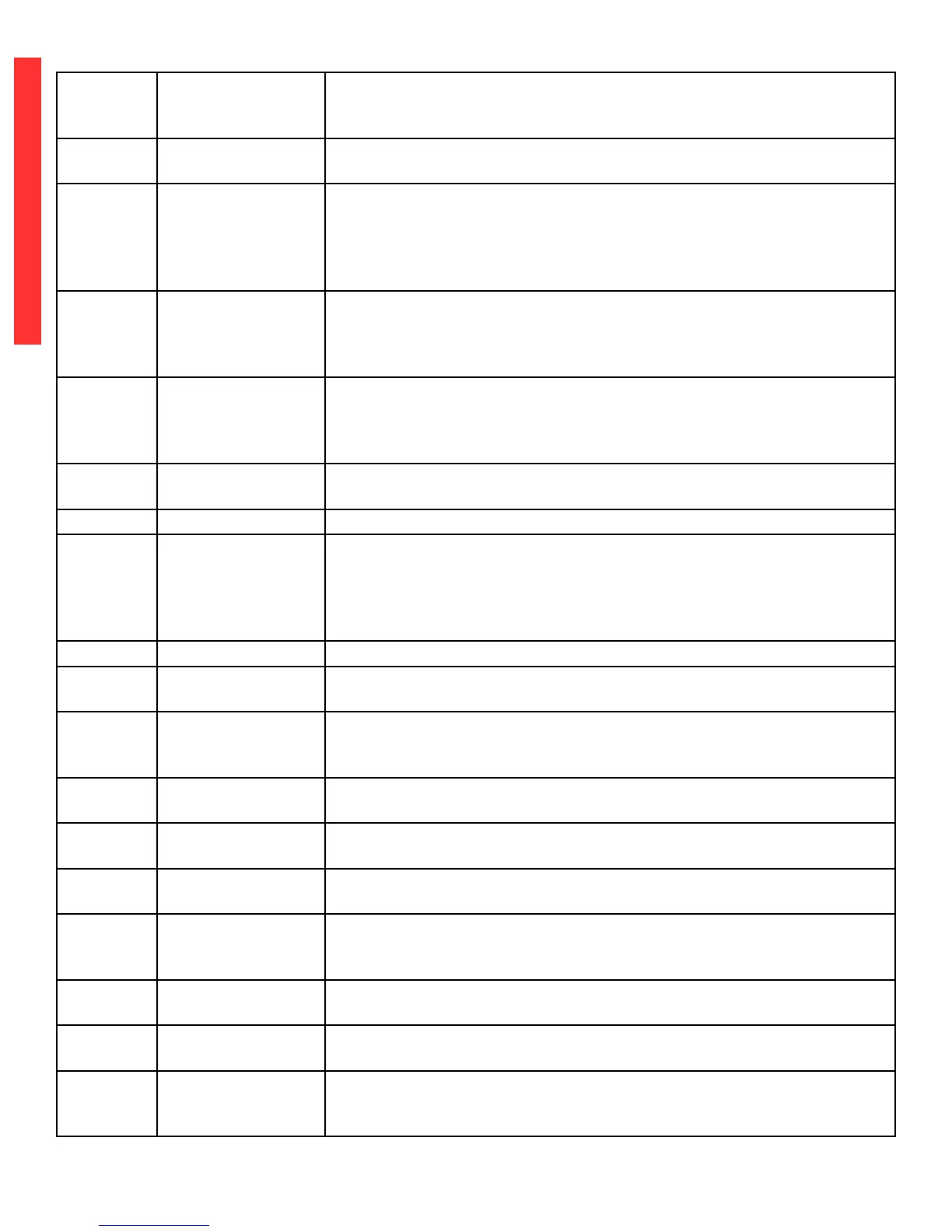

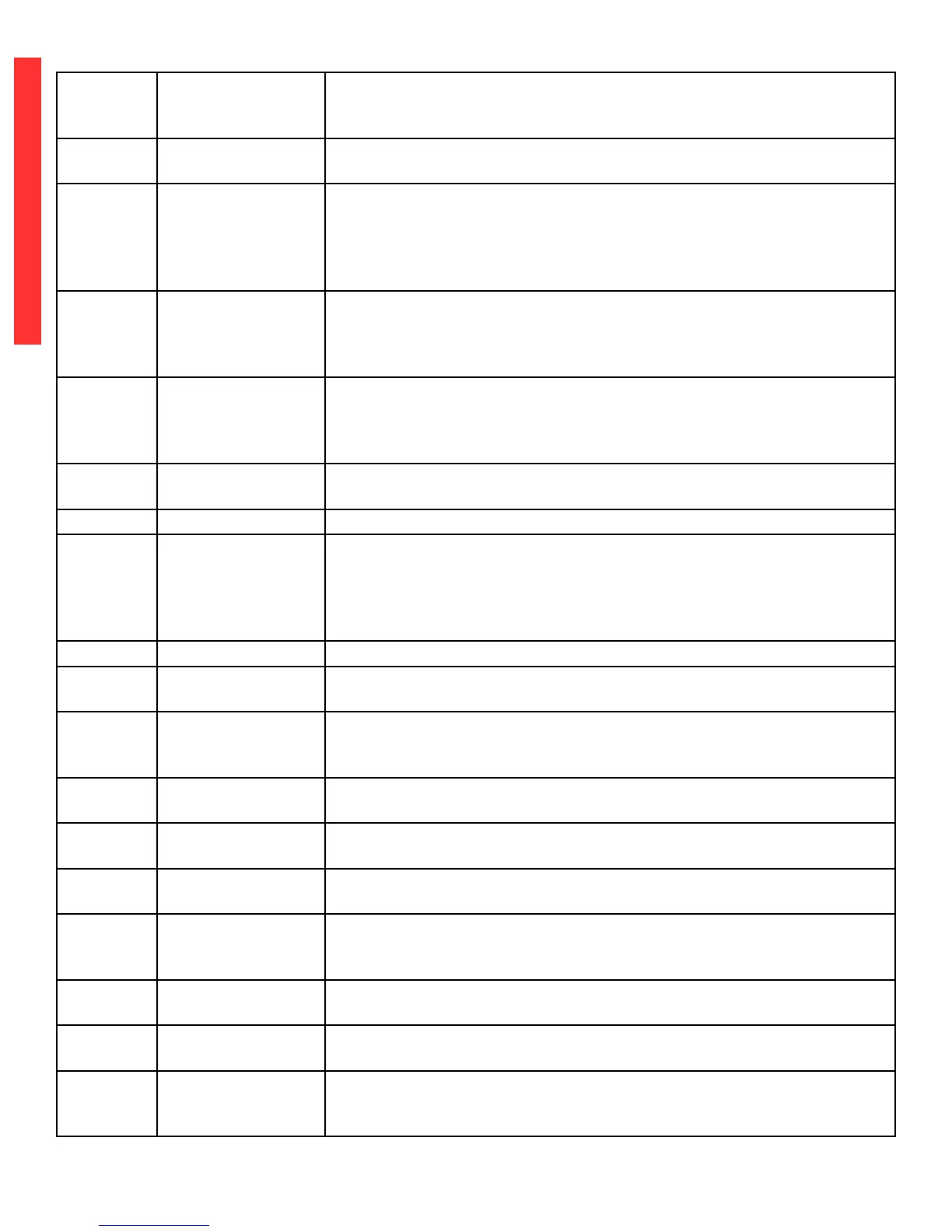

Technical Manual 32

● Working from a static tank and there is no pressure available to ll the

steam tank. Dual inlet machines will need a line boost pump or custom

plumbing to operate from a static tank with no line pressure.

● Machine is not level. Check to make sure the surface that holds the ma-

chine is level. Slightly adjust leg height to create a level machine

The Sight Glass

Shows that the

Water Level in the

Steam Tank is either

too High or too Low

● Water level probe (auto ll) needs to be de-scaled or cleaned. This

probe is located behind the left side panel

● On machines built prior to 01-01-2011, The manual ll switch located

on the front of the electrical box has been depressed. Use the hot water

spout to drain the steam tank until the ll solenoid opens and the tank

begins to rell.

● If you are working from a static tank then you must use a line pressure

boost pump to provide the pressure needed to ll the steam tank. Contact

your dealer, service provider, or the Synesso factory for more information

regarding static tank installations.

● Machine is not level. Check to make sure the surface that holds the ma-

chine is level. Slightly adjust leg height to create a level machine

● Debris is stuck in the water control ll valve. See Water Control Valves

Steam Tank is Slow

to Recover Pres-

sure

● On machines built prior to 01-01-2011, Test zone 5 functionality: ■

Turn down the set point for zone 4 a few degrees below zone 5 ■ Turn

up zone 5 by a few degrees and conrm that the temperature rises to the

new set point. ■ If the temperature has risen, then zone 5 is functioning

properly.

● Test zone 4 functionality. See Test zone 5 above for instructions.

● If either zone is not working properly, then see “Cold Zone” and “Tanks

will Not Heat to Full Temperature” in the Electronics section.

● Calcium and scale buildup can insulate and cause reduced efciency

in heating elements. If calcium and scale buildup is an issue, be sure to

descale your machine on a regular basis.

Steam

Wand

Drip at the Steam

Wand Tip

● Steam valve seal is worn. Replace by installing steam valve rebuilt kit.

● Steam valve handle needs to be adjusted. See Steam Valve Handle

Adjustment

● Steam valve is lled with milk residue. Disassemble steam valve and

clean.

Water bubbles out

around wand pivot

ball

● Wand ball o-ring is worn, replace with new teon o-ring from steam

valve rebuild kit.

Wand is Hard to

Move or Sticky

● Remove wand mounting nut, clean and lubricate wand ball with food

grade grease, replace wand ball o-ring

Steam Valve does

not Open Fully

● Steam valve handle needs to be adjusted. See Steam Valve Handle

Adjustment

Hot Water

Tap

No Water Flows

When the Switch is

On

● If there is pressure in the steam tank, and water to the machine is not

restricted, this indicates the switch has failed. Replace the switch.

TROUBLESHOOTING

Loading...

Loading...