Technical Manual 39

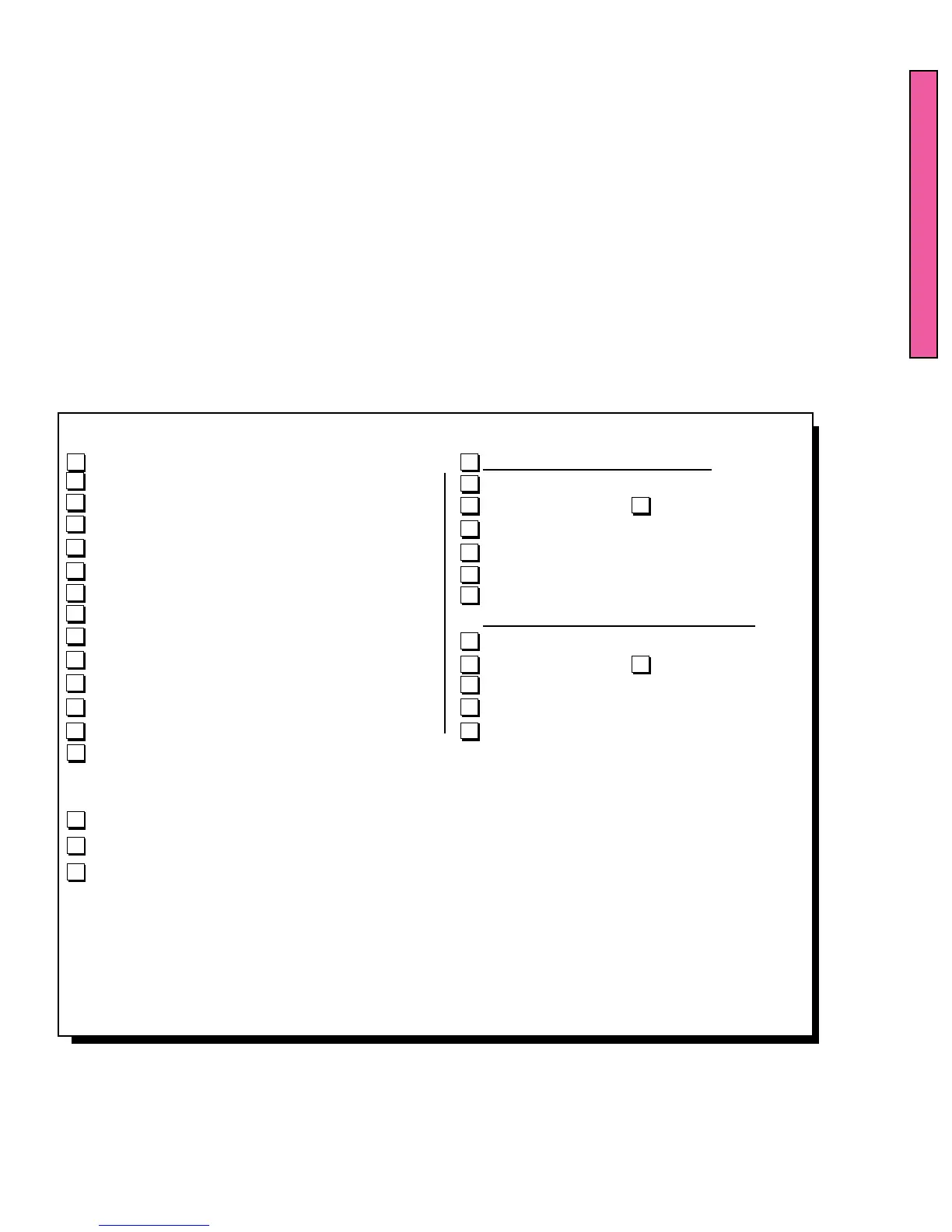

Preventative Maintenance Visit Checklist

Customer: ____________________ Phone:_____________ Date:_________

Serial Number: ____________________

Basic Service--Operational Inspection

Inspect or rebuild steam valves

Inspect or rebuild water control valves

Clean, adjust, lube steam valve acutators

Inspect all tube connections

Retorque element ange

Inspect drain system for leaks, clogs

Lube & adjust roller switches

Grease brass on brew switch threads

Inspect and clean autoll probe

Assess water hardness ___gpg

Inspect for scale buildup

Test brew pressure gauge

Clean steam wand tips

Check drain manifold hose connections

Replace the following parts:

Portalter Gaskets 8.0 8.6 9.0

Vacuum breaker VB o-ring

Sight glass o-rings

Hot water switch

Diffuser screens

Pump relay

Inspect and replace if necessary:

Pump and motor

Expansion valve EV rebuild

Hot water tap aerator

Braided steel hoses

Steam tube ball valves

*A checkmark in a box indicates that

this item was inspected, but not re-

placed. If a number is present in the

box, that indicates the quantity of this

part that was replaced.

Electrical inspection

Ensure electrical box is clean and dry

Inspect & clean temp probe connections

Check amp draw on all zones:

Z1___ Z2___ Z3___ Z4___ Z5___

Other parts used:__________________________________________________________

Technician comments / Suggested maintenance: _______________________________

_________________________________________________________________________

_________________________________________________________________________

**This is the form that Synesso™ uses when performing Preventative Maintenance visits.

Periodic Maintenance

PERIODIC MAINTENANCE

Loading...

Loading...