4 of 16

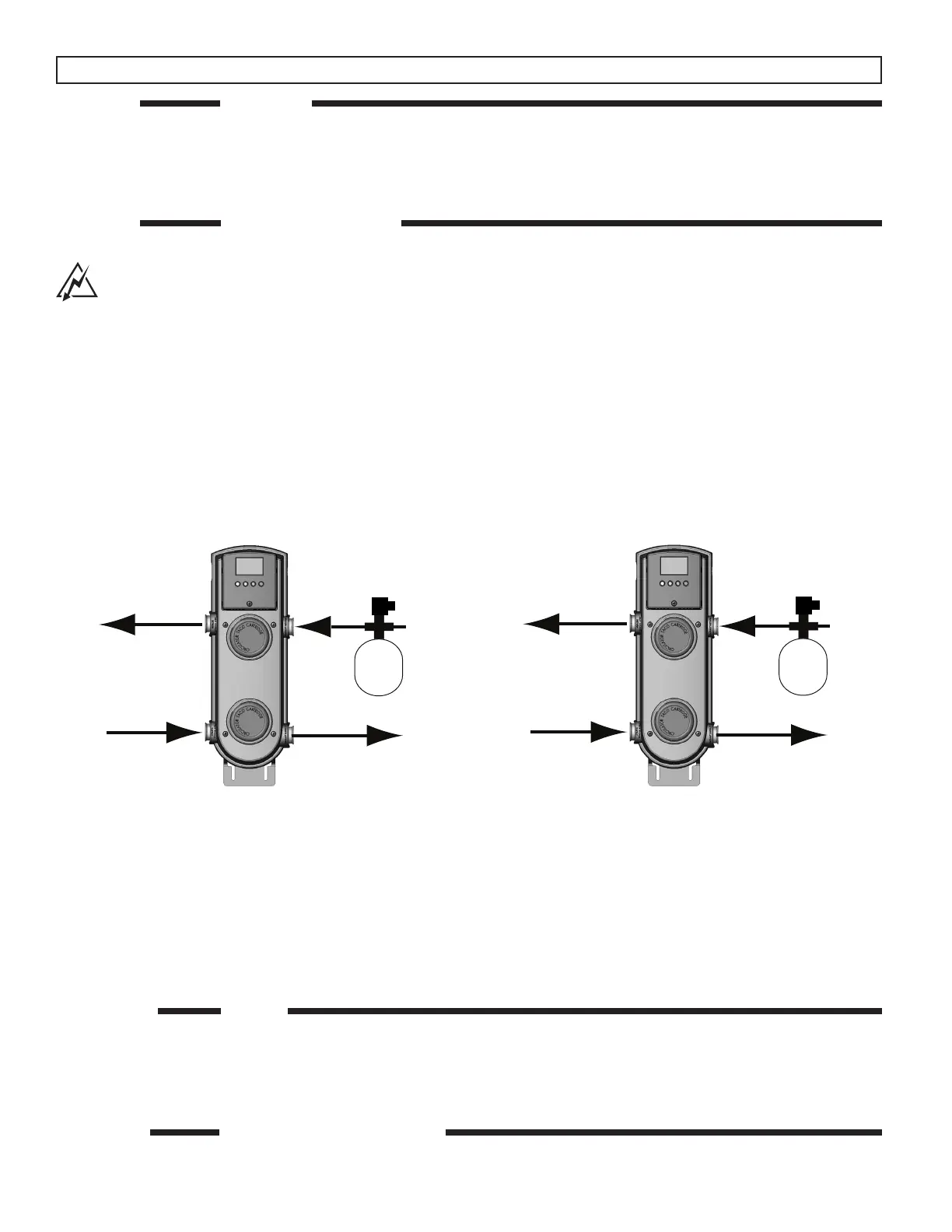

Snow

Return

Supply

Heat Source

Return

Heat Source

Supply

Exp

Tank

Pressure

Relief

Melt

Snow Melt

Variable

Flow

Constant

Flow

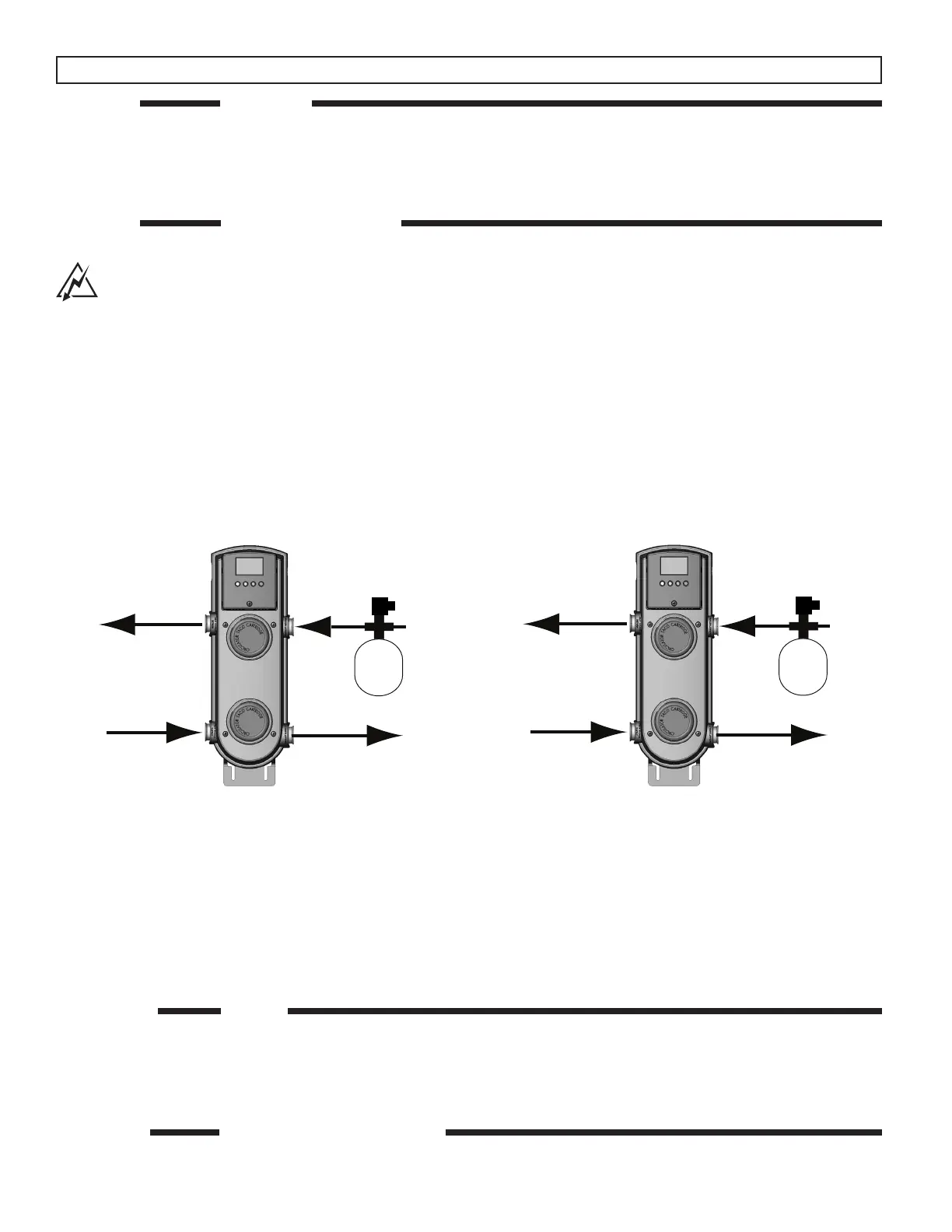

Radiant

Return

Radiant

Supply

Heat Source

Return

Heat Source

Supply

Exp

Tank

Pressure

Relief

Variable

Flow

Constant

Flow

When using the X - Pump Block on snow melting systems, it is recommended to switch the system pump motor with the variable

speed pump motor to protect the brazed plate heat exchanger from freezing up.

Follow the instructions for cartridge replacement (page 14) to disassemble the X – Pump.

Unbolt the fixed speed system pump motor (lower) and switch it with the heat source variable speed pump motor (upper).

This now insures constant flow on the heat source side of heat exchanger by the fixed speed pump to minimize the chance of freeze

up. The snow melt system pump is now variable speed and both the System Supply Sensor and System Return Sensor must be

installed and in Setpoint with delta T max mode.

STEP THREE FILLING

1. Fill both system and heat source with tap water – The system must be filled before operating the circulator. The bearings are water

lubricated and should not be allowed to operate dry. Filling the system will result in immediate lubrication of the bearings. It is always

good practice to flush a new system of foreign matter before starting the circulator.

2. Circulator operation – Operate the circulators for 5 minutes immediately after filling system to purge remaining air from the bearing

chamber. This is especially important when installing the circulator during the off-season.

STEP FOUR ELECTRICAL CONNECTIONS

1. Observe all applicable codes when connecting to power supply. The motors are impedance protected, and do not require overload

protection. The pumps cannot run backwards.

STEP ONE MOUNTING

1. Mounting position – The X – Pump Block must be mounted in the vertical position with the Variable Speed Mixing Control (VSMC)

located at the top of the X – Pump Block.

2. Mount the X – Pump Block, using the attached brackets, to a solid surface capable of supporting 23.5 pounds.

3. Using four suitable screws or bolts (

1

⁄

4

”), fasten the X – Pump Block to the selected location. Ensure that at least two of the mounting

screws are attached to a wall stud or similar surface.

STEP TWO PIPING CONNECTIONS

1. Using proper piping practices, connect the supply to the radiant heating system to the Radiant Supply (bottom right hand connec-

tion) as indicated on the plastic cover of the X – Pump Block. Ensure that a proper isolation valve is installed.

2. Using proper piping practices, connect the return from the radiant heating system to the Radiant Return (top right hand connection)

as indicated on the plastic cover of the X – Pump Block. Ensure that a proper isolation valve is installed.

3. Using proper piping practices, connect the supply from the heat source to the Heat Source Supply (bottom left hand connection) as

indicated on the plastic cover of the X – Pump Block. Ensure that a proper isolation valve is installed.

4. Using proper piping practices, connect the return to the heat source to the Heat Source Return (top left hand connection) as

indicated on the plastic cover of the X – Pump Block. Ensure that a proper isolation valve is installed.

5. When using a non-condensing heat source as heat source, connect the Heat Source Supply and Heat Source Return lines of the

X – Pump Block to the heat source loop using standard Primary Secondary piping practices.

Installation of the X – Pump Block

Warning! Must Install a pressure relief valve and expansion tank on secondary side in addition to units

installed on primary side of system. Note! Heat should never be applied to X – Pump Block connections

or damage to housing and/or electronics may result.

Refer to Page 2 for More Piping Diagrams

Loading...

Loading...