Starting

CAUTION

Before starting, make sure the cutting

attachment does not touch anything.

1. Set ignition switch (7) to ON position (A). (Fig. 4,

5)

7

A

8

Fig. 4

A

8

7

9

Fig. 5

* Push priming bulb (10) several times so that

fuel fl ows through the bulb or return pipe. (If so

equipped) (Fig. 6)

10

Fig. 6

2. With the safety lever (8) pressed, pull throttle

trigger and push lock button (9) (If so equipped),

then slowly release throttle the trigger fi rst, then

the safety lever. This will lock the throttle in

starting position. (Fig. 4, 5)

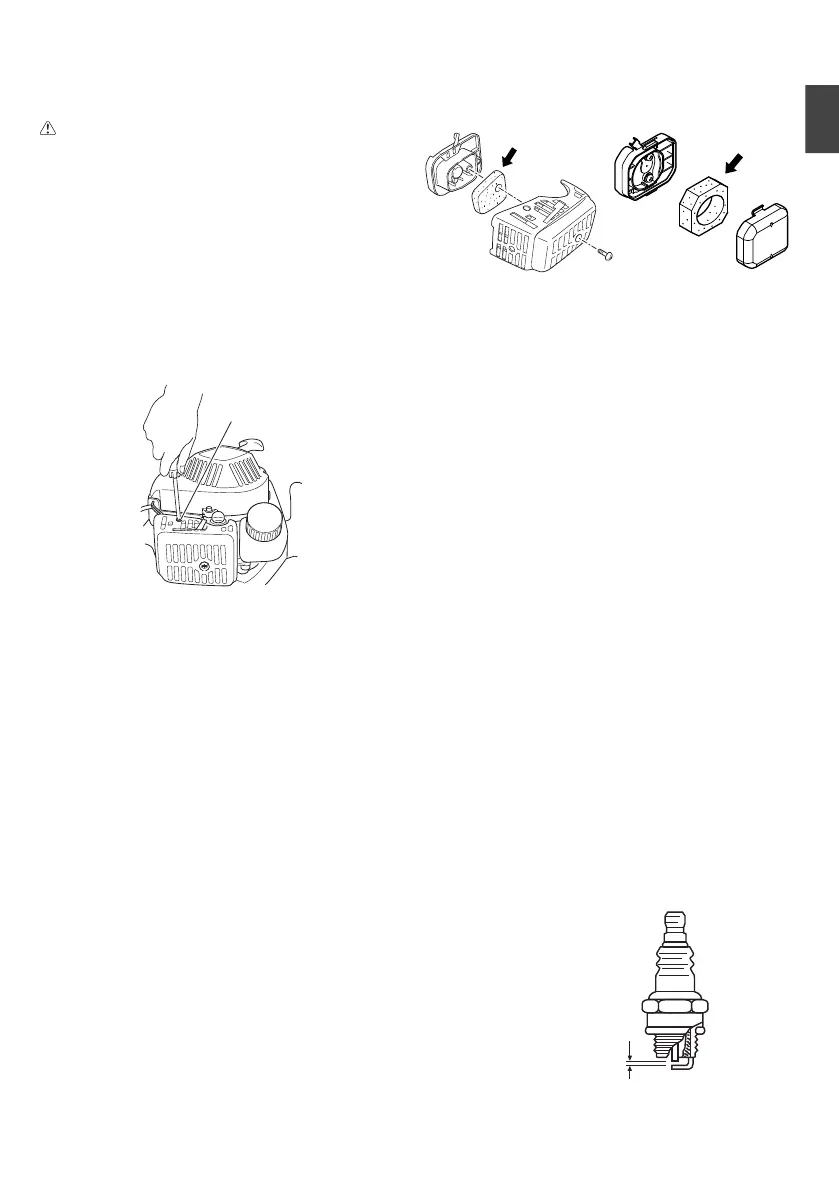

3. Set choke lever (11) to CLOSED position (B).

(Fig. 7)

11

BC

Fig. 7

4. Pull recoil starter briskly, taking care to keep the

handle in your grasp and not allowing it to snap

back. (Fig. 8, 9)

Fig. 9Fig. 8

5. When you hear the engine attempts to start,

return choke lever to RUN position (open) (C).

Then pull recoil starter briskly again.

NOTE

If engine does not start, repeat procedures from 2

to 4.

6. After starting engine, allow the engine about 2-3

minutes to warm up before subjecting it to any

load.

Cutting

When cutting, operate engine at full throttle as this

maintains proper cutter speed. When trimming top

of hedge, hold trimmer so blades are between 15

and 30 degrees from a horizontal position and swing

trimmer in an arc toward edge of hedge to sweep

cuttings off . When trimming sides of hedge, hold

blade vertically and swing unit in an arc.

NOTE

○ Multi-position twist handle (Fig. 10, 11)

(except single blade)

The rear control handle turns 70 degrees to

provide comfortable use while accommodating a

variety of cutting angles. The handle allows for

fi ve diff erent locking positions. Before attempting

to adjust rear handle, make sure the machine is

at idle or engine is shut off .

○ The machine will automatically shut off if the

throttle lever is pressed while the handle is NOT

secured in one of the fi ve preset positions. Never

attempt to operate the machine unless the rear

handle is properly locked in place.

To rotate the handle; push the lock lever (12)

allowing the handle to turn. When the mark (13)

on the rear handle aligns with the mark (14) on

the frame/gear case, push the lock lever back to

the locked position.

D: LOCK

E: UNLOCK

9

G

B

F

R

E

S

000BookTHT210BUS.indb9000BookTHT210BUS.indb9 2009/07/1318:22:272009/07/1318:22:27

Loading...

Loading...