50

Multi Smith Pro

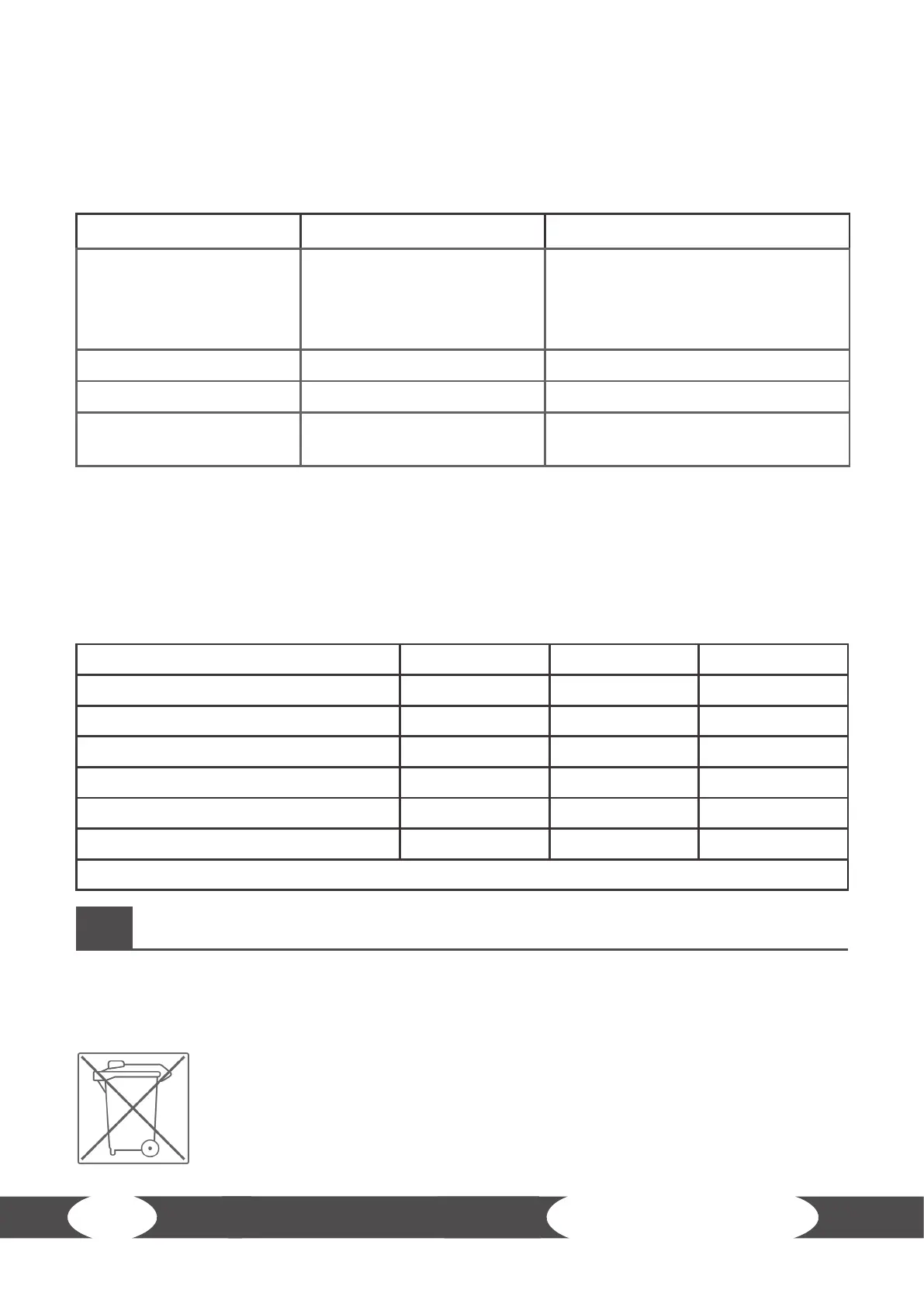

4.2 Faults and Fault Diagnosis

The equipment undergoes regular quality controls during production. Nevertheless, faults or

malfunctions may occur. Frequently, individual parts are responsible for these disturbances, an

exchange is usually sucient. Please refer to the following overview for the most common errors and

how to correct them. If the equipment still does not function properly, contact your contract partner.

Fault Cause Solution

Grinding noises

Cables or pulleys do not run

smoothly or are damaged

+ Visual inspection of the cable

routing or the pulley guide

+ If damaged, replace the defective

part

Weight hanging in the air Cable tensioned too tight Readjust cable tension

Cable without tension Cable too loose Readjust cable tension

Squeaking & cracking

noises

Screw connections loosened

or too tight

Check screw connections

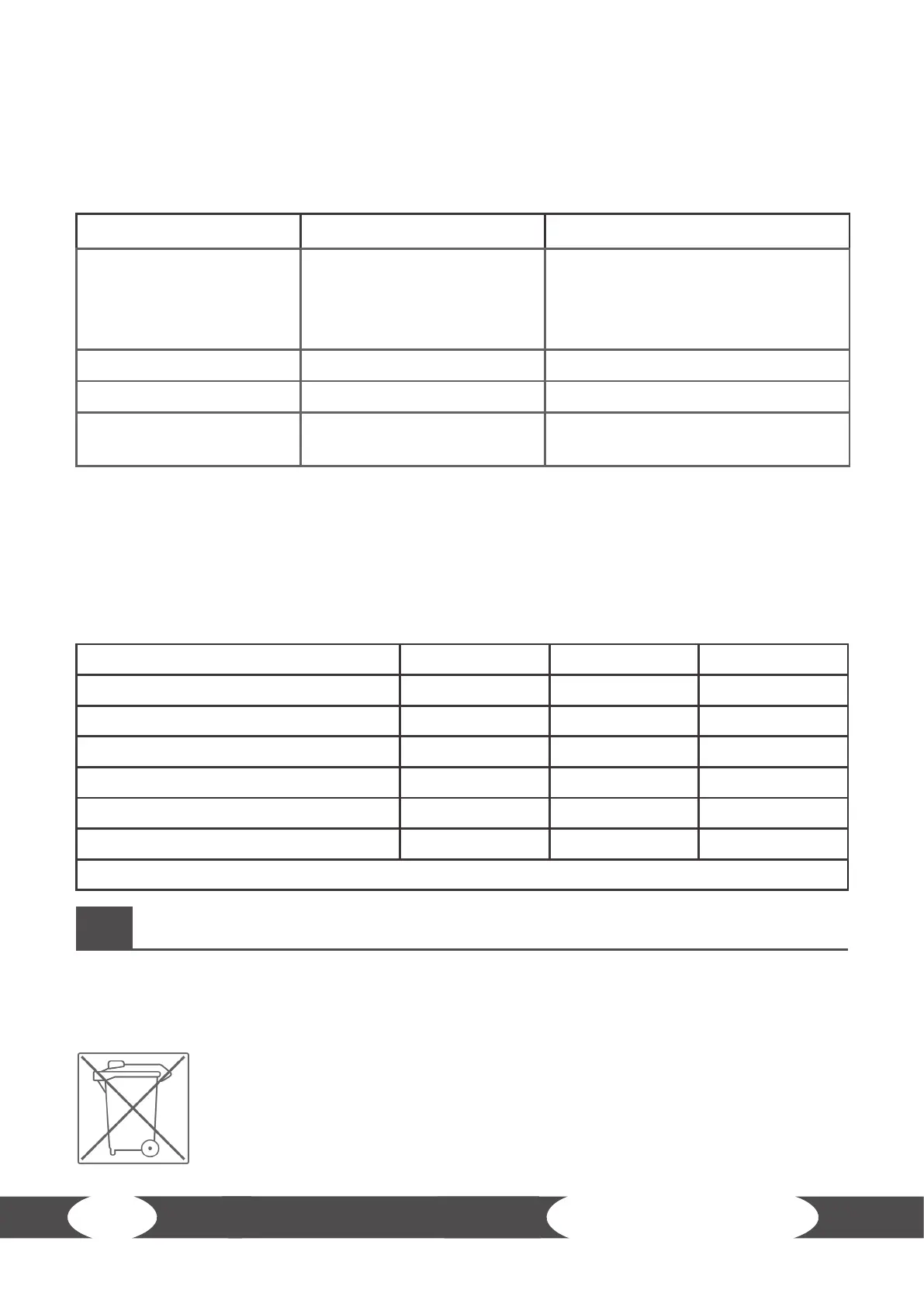

4.3 Maintenance and Inspection Calendar

To avoid damage from body sweat, the equipment must be cleaned with a damp towel (no solvents!)

after each training session.

The following routine tasks must be performed at the specied intervals:

Part Weekly Monthly Quarterly

Cables C I

Screw connections I

Pulleys and cable routing I

Slide rails/Guide rods I

Weights I

Cushions C I

Legend: C = clean; I = inspect

5 DISPOSAL

At the end of its operational life, this equipment cannot be disposed of in normal household waste.

Instead, it must be disposed of via an recycling centre. Further information can be obtained from

your local authority‘s recycling service.

The materials can be recycled as per their symbols. Through the reuse, recycling

of materials or other forms of recovery of old equipment, you make an important

contribution to the protection of the environment.

Loading...

Loading...