8-2

TROUBLESHOOTING GUIDE

Model SB25

Troubleshooting Guide

8

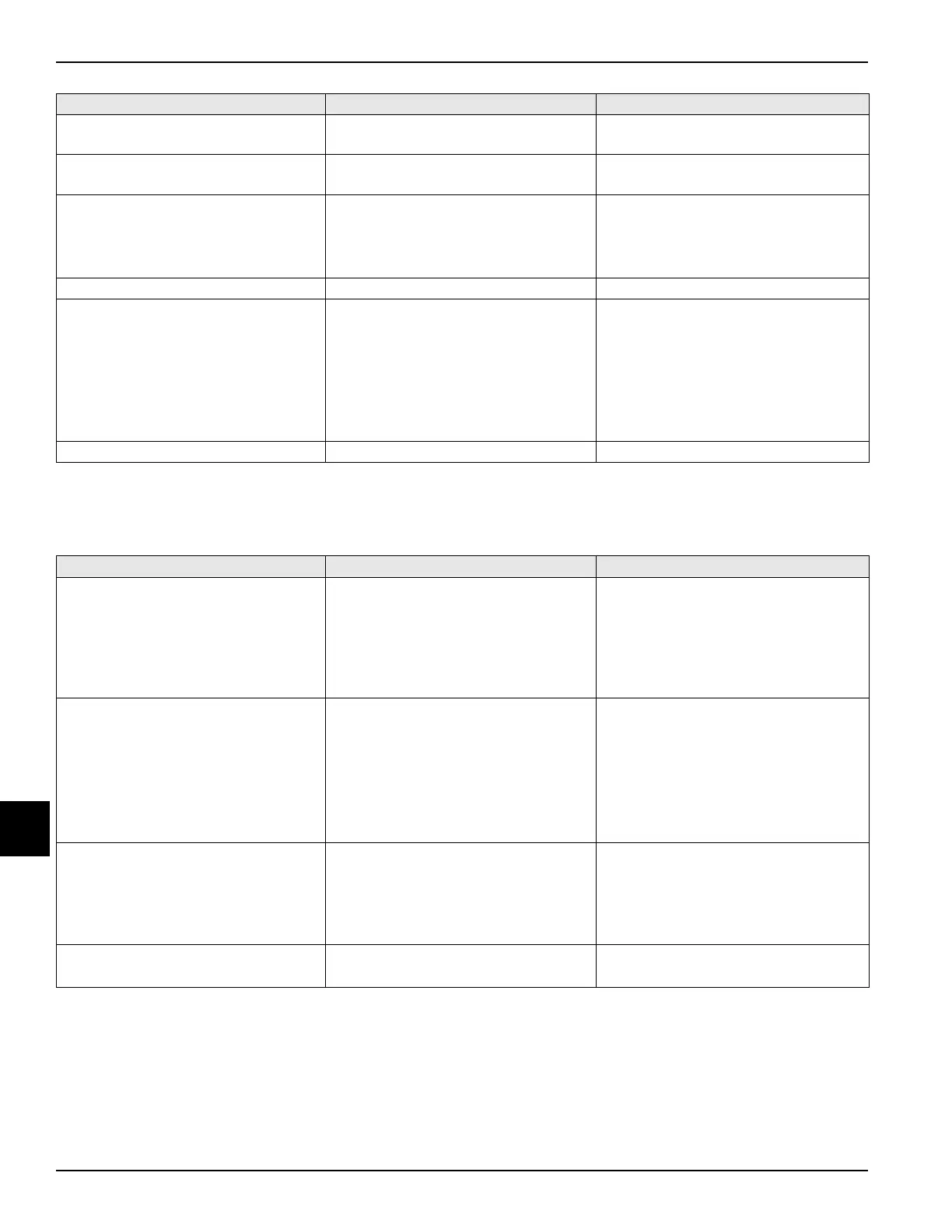

Rinse Station Troubleshooting

Table 8-2

13. Recipe key #4 - slow blink (low bus

voltage).

a. Low voltage supplied to machine. a. Contact a Taylor service technician.

14. Recipe key #1, 2, 3, or 4 - fast blink

(communication fault).

a. No communication between keypad

and dispense board.

a. Contact a Taylor service technician.

15. Machine runs but does not shave

ice.

a. Ice hopper is empty. a. Refill the hopper.

b. Shaver blade guard has not been

removed.

b. Call authorized service technician to

remove the guard.

c. Shaver blade is damaged. c. Contact a Taylor service technician.

16. Shaved ice has inconsistent texture. a. Shaver blade is worn. a. Contact a Taylor service technician.

17. Machine runs but does not blend

ice.

a. Wrong volume or product was added. a. Remeasure and pour product.

b. Wrong volume of ice. b. Check the ice volume. Adjust

calibration as needed.

c. Wrong volume of water. c. Check the water volume. Adjust

calibration as needed.

d. Wrong volume of cane (115V 60 Hz

machine only).

d. Check the cane volume. Adjust

calibration as needed.

18. Blender pitcher is damaged. a. Abuse or excessive wear. a. Replace the blender pitcher.

PROBLEM PROBABLE CAUSE REMEDY

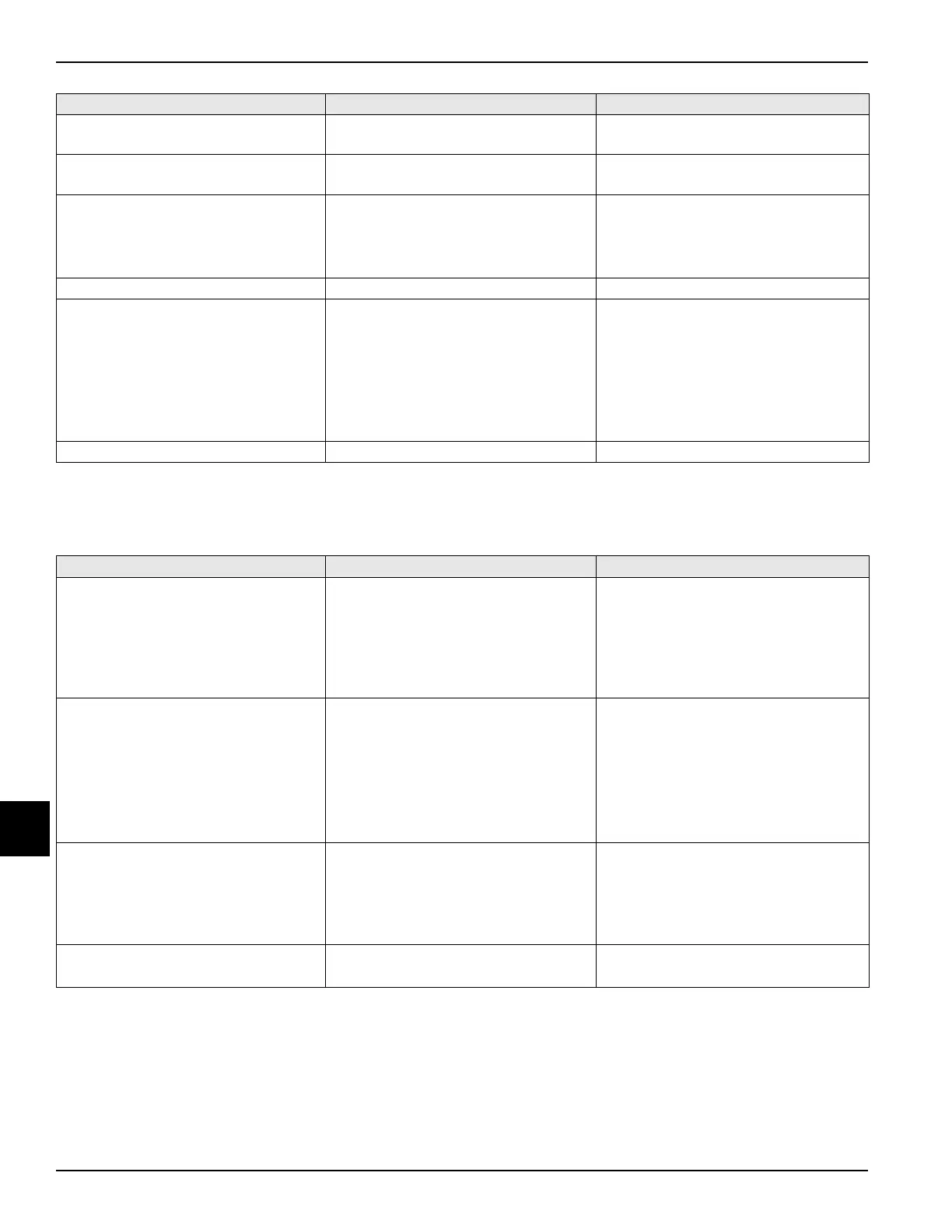

19. Machine will not rinse. a. The power switch is in the OFF

position.

a. Place the power switch in the ON

position.

b. The power plug is not inserted into

the power jack.

b. Check the connection at the rear of

the machine.

c. The DC converter is not plugged into

the wall jack.

c. Check the connection at the rear of

the machine.

20. Blender pitcher is not being rinsed

completely.

a. The water line at the back of the

machine is not connected.

a. Connect the water line.

b. The water line is kinked. b. Straighten the water line.

c. Cold water is being used for rinsing. c. Use warm water to aid in the rinsing

process.

d. Rinse cycle is not long enough. d. Call an authorized service technician.

e. Low water pressure in the store. e. Call an authorized service technician.

21. Water is leaking from the machine. a. Poor fitting/hose connection. a. Check all visible fittings and ensure

all hoses are fitted into the fittings

properly.

b. Cracked hose b. Call an authorized service technician.

c. Broken fitting. c. Call an authorized service technician.

22. Machine is not draining. a. Drain line is kinked. a. Straighten the drain line.

b. Drain line is clogged. b. Clear the drain line.

PROBLEM PROBABLE CAUSE REMEDY

Loading...

Loading...