OPERATING PROCEDURES

6-7

Model SB25

Operating Procedures

6

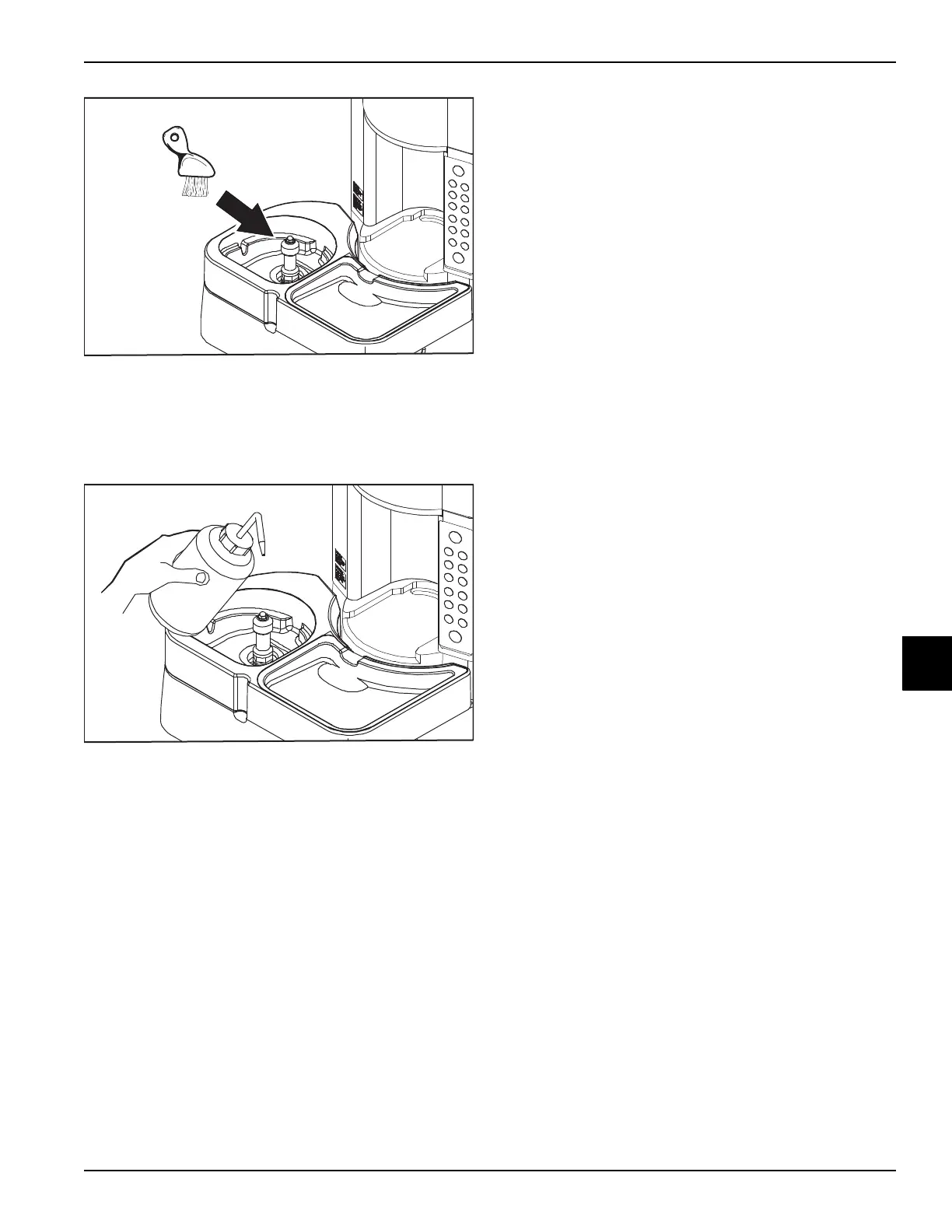

Figure 6-19

30. For machines equipped with the Rinse Station:

Using the squeeze bottle filled with cleaning/

sanitizing solution, thoroughly flush the Rinse Station

area. (

See Figure 6-20.)

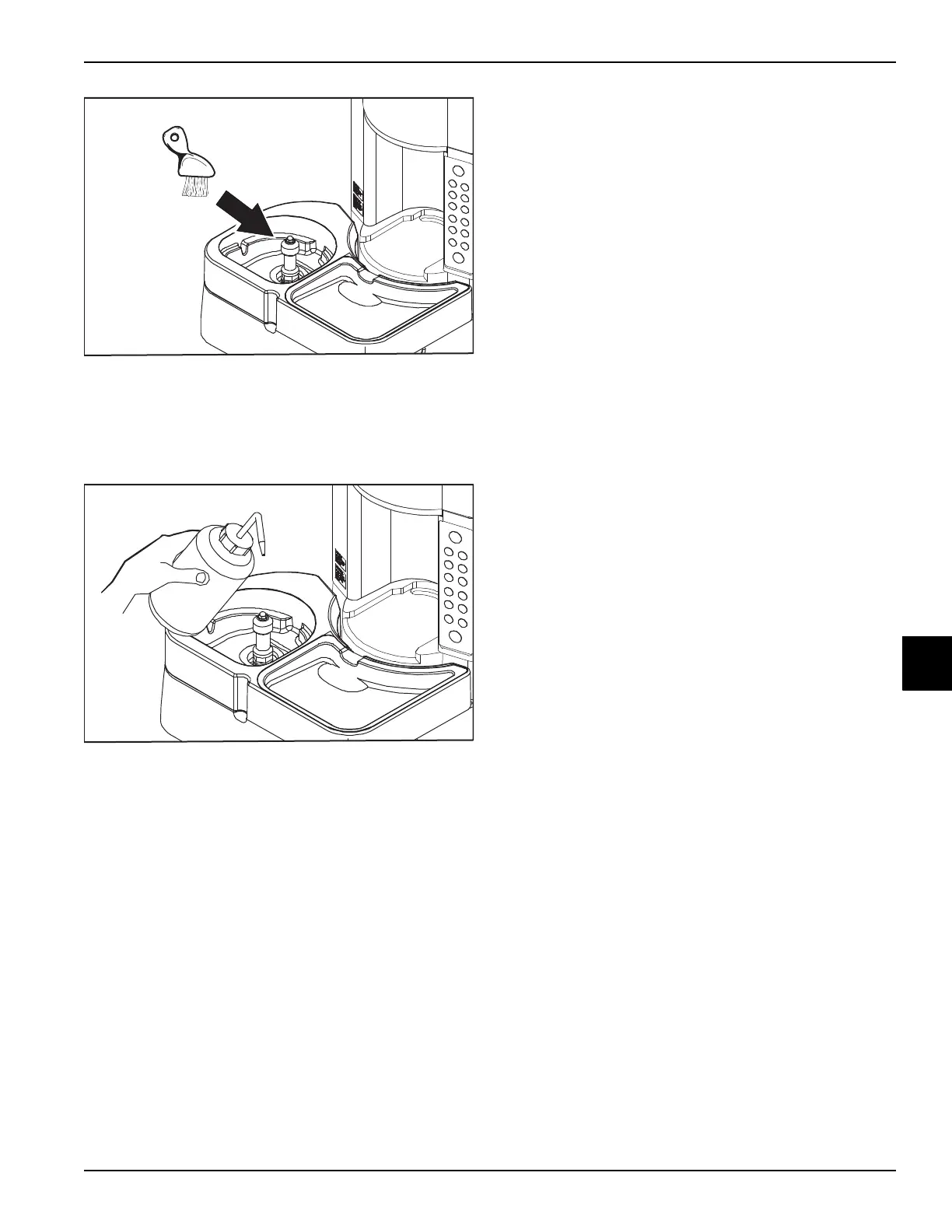

Figure 6-20

31. Fill the squeeze bottle with an approved cleaning/

sanitizing solution with an active chlorine concentrate

of 100 PPM to 200 PPM.

32. Repeat steps 22 to 29 using the cleaning/ sanitizing

solution.

33. Wipe the exterior of the machine with cleaning/

sanitizing solution.

34. For machines equipped with the Rinse Station:

Wipe the exterior of the Rinse Station.

Weekly Cleaning and Sanitizing of

Cane Sugar System

(115V 60 Hz

Machines)

1. Perform the Daily Cleaning and Sanitizing

Procedures before proceeding to the next step.

2. Prepare a 2.5 gal. (9.5 L) pail with warm water.

3. Prepare a 2.5 gal. (9.5 L) pail of a cleaning/sanitizing

solution with an active chlorine concentrate of

100 PPM to 200 PPM. Use warm water and follow

the Taylor-approved manufacturer's specifications.

This pail will be usedfor cleaning.

4. Prepare another 2.5 gal. (9.5 L) pail of a cleaning/

sanitizing solution with an active chlorine concentrate

of 100 PPM to 200 PPM. Use warm water and follow

the Taylor-approved manufacturer's specifications.

This pail will be used for sanitizing.

5. Remove the dip tube from the cane sugar container

or disconnect it from the BIB. Place the dip tube in

the pail filled with warm water.

6. Place the blender pitcher on the blender base.

Note: Remove and empty the pitcher as needed

during the cleaning procedure.

7. Press and hold the “NO SUGAR” key to start the

cane pump. Continue holding the key until the pail is

half empty. This will rinse the cane pump and the

dispense tube.

8. Remove the dip tube from the pail and place it into

the pail filled with cleaning/sanitizing solution. Repeat

the process described in step 7 to clean the cane

pump and the dispense tube.

9. Remove the dip tube from the pail and place it into

the pail filled with cleaning/sanitizing solution. Repeat

the process described in step 7 to sanitize the cane

pump and the dispense tube.

10. Remove the dip tube from the cleaning/sanitizing

solution. Allow the pump to continue to run to purge

the sanitizer from the cane system.

11. Reinstall the dip tube into the cane sugar container or

reconnect to the BIB and perform the priming

process.

Cane Priming (115V 60 Hz Machines)

The cane line must be primed when the machine is

started for the first time, when replacing an empty

cane bottle, and after performing the weekly cleaning

and sanitizing of the case sugar system.

1. Place a blender pitcher on the blender base.

2. Press and hold the NO SUGAR key for 3 seconds.

This will start the cane pump and prime the cane line.

3. Rinse, brush-clean, and sanitize the blender pitcher.

Loading...

Loading...