TX / TXH / TXB 180S - 400L (Rev. 4/23/07)TX / TXH / TXB 180S - 400L (Rev. 4/23/07)

9C-129C-12

Also when a Also when a fault, related to fault, related to the parameter settings, located the parameter settings, located in FLASH memory in FLASH memory is detected, the is detected, the controllercontroller

reverts to shutdown mode.reverts to shutdown mode.

The GPOS / CPOS display indicates the letters ‘Sd’ on the left two digits of the direction/positionThe GPOS / CPOS display indicates the letters ‘Sd’ on the left two digits of the direction/position

indication.indication.

Shifter LeverShifter Lever

The main interface with the driver is the sThe main interface with the driver is the shift leverhift lever. . It allows selecting the driving direction and theIt allows selecting the driving direction and the

different ranges. different ranges. The shift lever output The shift lever output signals serve as inputs fsignals serve as inputs for the APC.or the APC.

For automatic mode, the shift lever position will limit the gear in which the controller is allowed to shift to.For automatic mode, the shift lever position will limit the gear in which the controller is allowed to shift to.

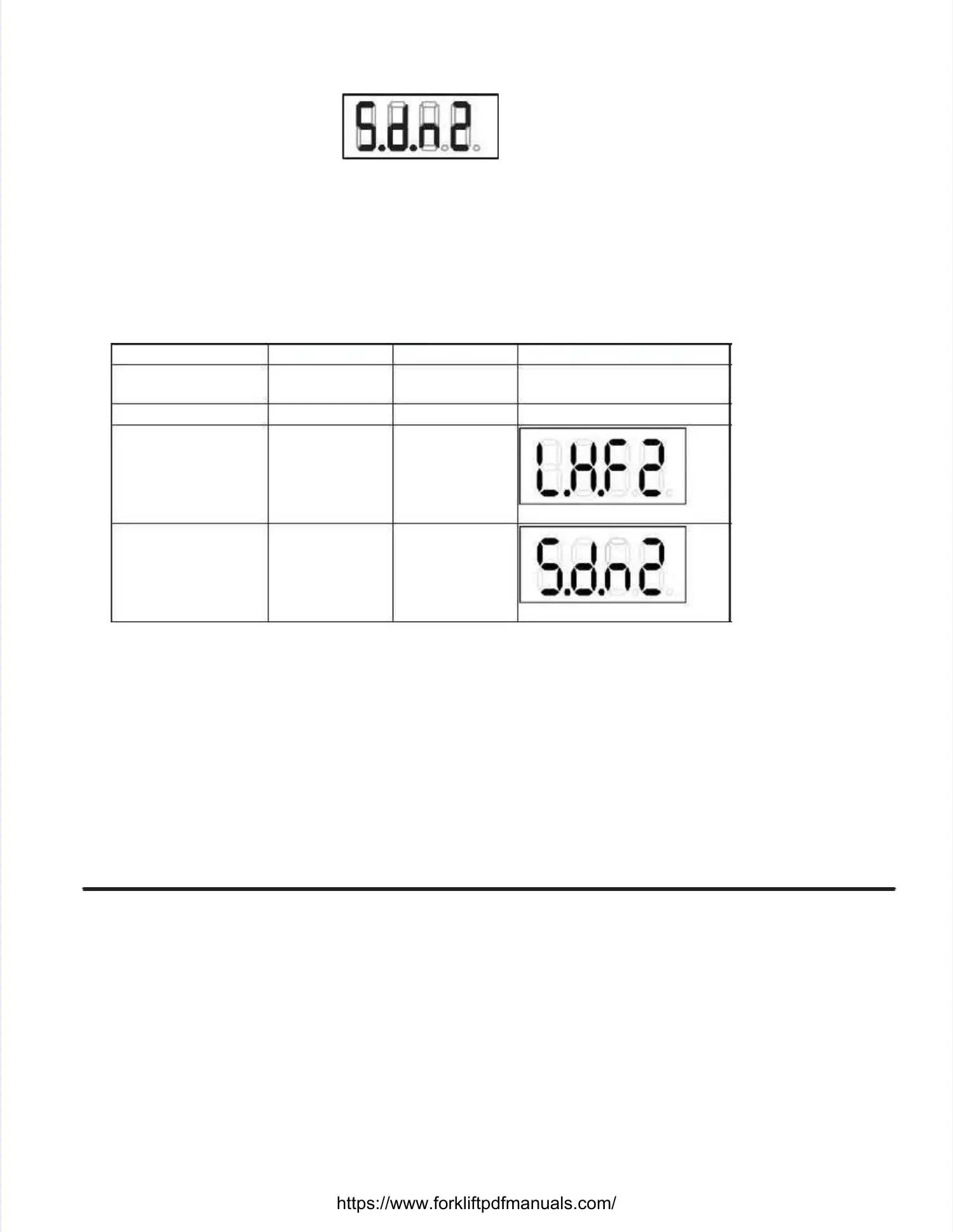

Mode IdentificationMode Identification

The above modes are identified as follows:The above modes are identified as follows:

MMooddee DD––lleedd EE––lleedd DDiissppllaayy

NNoorrmmaal l ddrriivviinngg OOffff aas s ppeer r eerrrroorr

SSeellf f tteesstt OOnn OOffff ddeessccrriibbeed d iin n 44..1188

LLiimmp p hhoommee OOffff BBlliinnkkiinngg

SShhuut t DDoowwnn OOffff BBlliinnkkiinngg

Diagnostics and GuidelinesDiagnostics and Guidelines

Diagnostics and MaintenanceDiagnostics and Maintenance

GeneralGeneral

Principally there are no specific devices required for first level troubleshooting as the APC incorporatesPrincipally there are no specific devices required for first level troubleshooting as the APC incorporates

several self–test features assseveral self–test features assisting in this process. isting in this process. Nevertheless, use of digital Nevertheless, use of digital multi–meters and simplemulti–meters and simple

tools such as an indicator tools such as an indicator lamp will be required to pinpoint lamp will be required to pinpoint exact causes of problemexact causes of problems. s. More indepthMore indepth

troubleshooting and system tuning involves use of a WIN95 Compatible PC with appropriate software andtroubleshooting and system tuning involves use of a WIN95 Compatible PC with appropriate software and

FLASH parameter programming equipment. FLASH parameter programming equipment. The APC allows recall The APC allows recall and modification of non–volatand modification of non–volatileile

parameters through RS232. parameters through RS232. This wayThis way, customers can, given the necessary equipment, choose to adapt, customers can, given the necessary equipment, choose to adapt

certain parameters to suit their needs. certain parameters to suit their needs. From a maintenance point of viewFrom a maintenance point of view, this is relevant in so , this is relevant in so far that thefar that the

APC allows reading APC allows reading back the (modified) back the (modified) parameters along with parameters along with serial number, part number andserial number, part number and

modification date. modification date. Several PC hosted tools have Several PC hosted tools have been developed to ease the servicbeen developed to ease the service and troubleshootinge and troubleshooting

process.process.

S lf Di ti F tiS lf Di ti F ti

https://www.forkliftpdfmanuals.com/

Loading...

Loading...