TX / TXH / TXB 180S - 400L (Rev. 4/23/07)TX / TXH / TXB 180S - 400L (Rev. 4/23/07)

17-217-2

22

77

99

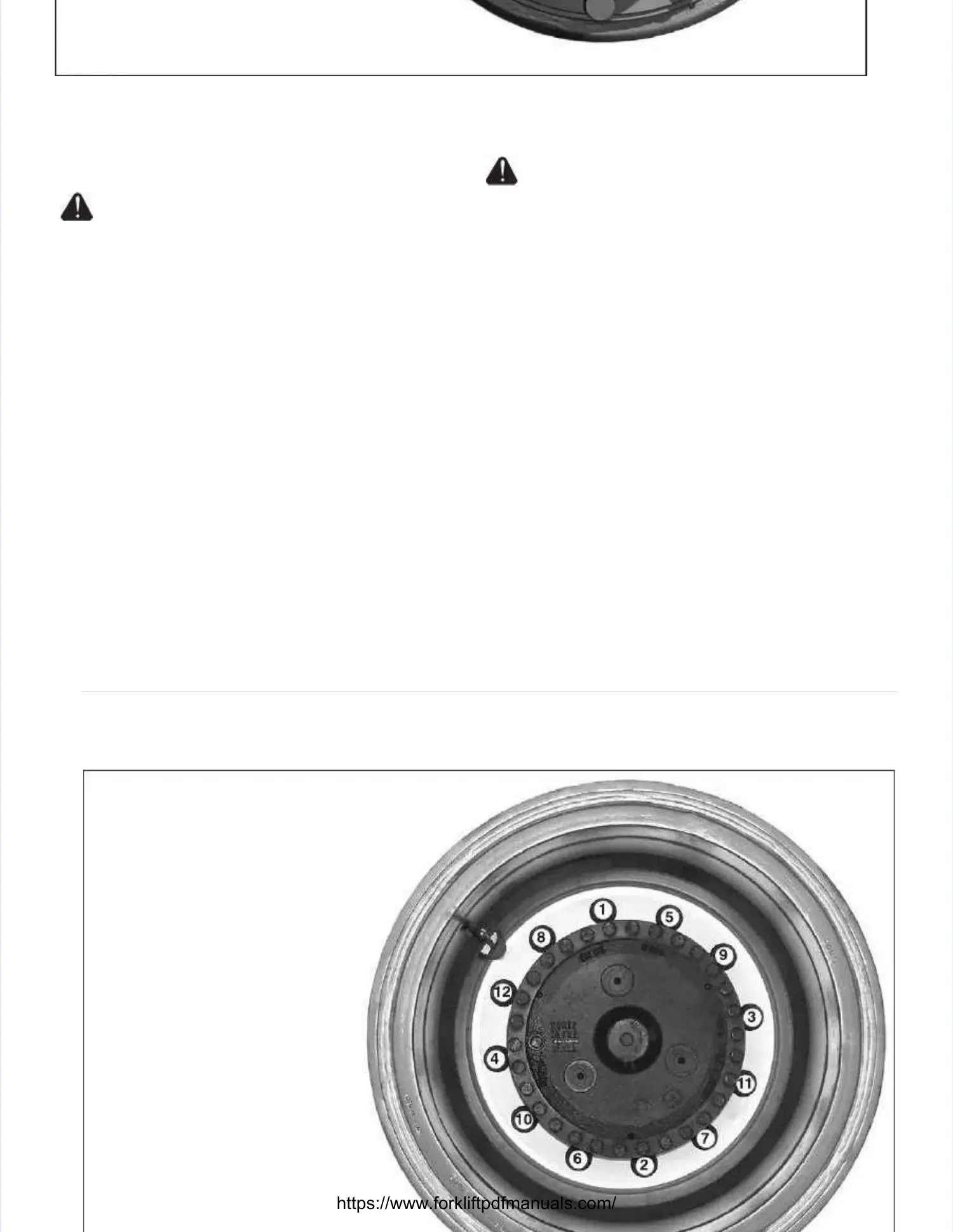

Illustration 17-1. Illustration 17-1. Drive Axle Wheel Drive Axle Wheel Nuts TNuts Torquing Sequence (TX180S - 360L)orquing Sequence (TX180S - 360L)

Torquing ProcedureTorquing Procedure (Illustrations 17-1 through(Illustrations 17-1 through

17-4)17-4).. Perform the Perform the following procedures following procedures to torqueto torque

the wheel nuts:the wheel nuts:

Every time the wheels areEvery time the wheels are

removed, a removed, a run-in perrun-in period is iod is required. required. TheThe

wheel nuts must be re-torqued every 10 hourswheel nuts must be re-torqued every 10 hours

of operation until rims are fully seated.of operation until rims are fully seated.

1.1. StaStart at port at positsition #1 aion #1 and tignd tightehten the whn the wheel nueel nutt

to the to the specified torque specified torque value listed. value listed. ProceedProceed

in the illustrated numerical order to torque thein the illustrated numerical order to torque the

other wheel nuts.other wheel nuts.

2.2. RepRepeat preat proceocedurdure 1. unte 1. until no whil no wheel nueel nut movt moveses

when the proper when the proper torque value is torque value is applied. applied. Pro-Pro-

cedure 1. may have to be repeated severalcedure 1. may have to be repeated several

times to tighten the wheel nuts to the propertimes to tighten the wheel nuts to the proper

torque value.torque value.

InspectionInspection

Mixing parts Mixing parts of one mof one manufacturer’s rims anufacturer’s rims withwith

those of another is those of another is potentially dangerous.potentially dangerous.

Always check manufacturer for approval.Always check manufacturer for approval.

Do Do not bnot be careless e careless or or take chances. take chances. If youIf you

are not sure about the are not sure about the proper mating of rimproper mating of rim

and wheel parts, consult a wheel and rimand wheel parts, consult a wheel and rim

expert. expert. This may bThis may be the tire e the tire man who iman who iss

servicing your fleet or the rim and wheelservicing your fleet or the rim and wheel

distributor in your area.distributor in your area.

1.1. MultiMulti-piece -piece rims rims and and all all rim rim compocomponents nents mustmust

be inspected before re-assembly each timebe inspected before re-assembly each time

the tire is removed from the rim for repair andthe tire is removed from the rim for repair and

each time the each time the tire is replaced. tire is replaced. Rims and all Rims and all rimrim

components should be inspected annually (orcomponents should be inspected annually (or

every 3,000 hours) otherwise.every 3,000 hours) otherwise.

Loading...

Loading...