TX / TXH / TXB 180S - 400L (Rev. 4/23/07)TX / TXH / TXB 180S - 400L (Rev. 4/23/07)

17-417-4

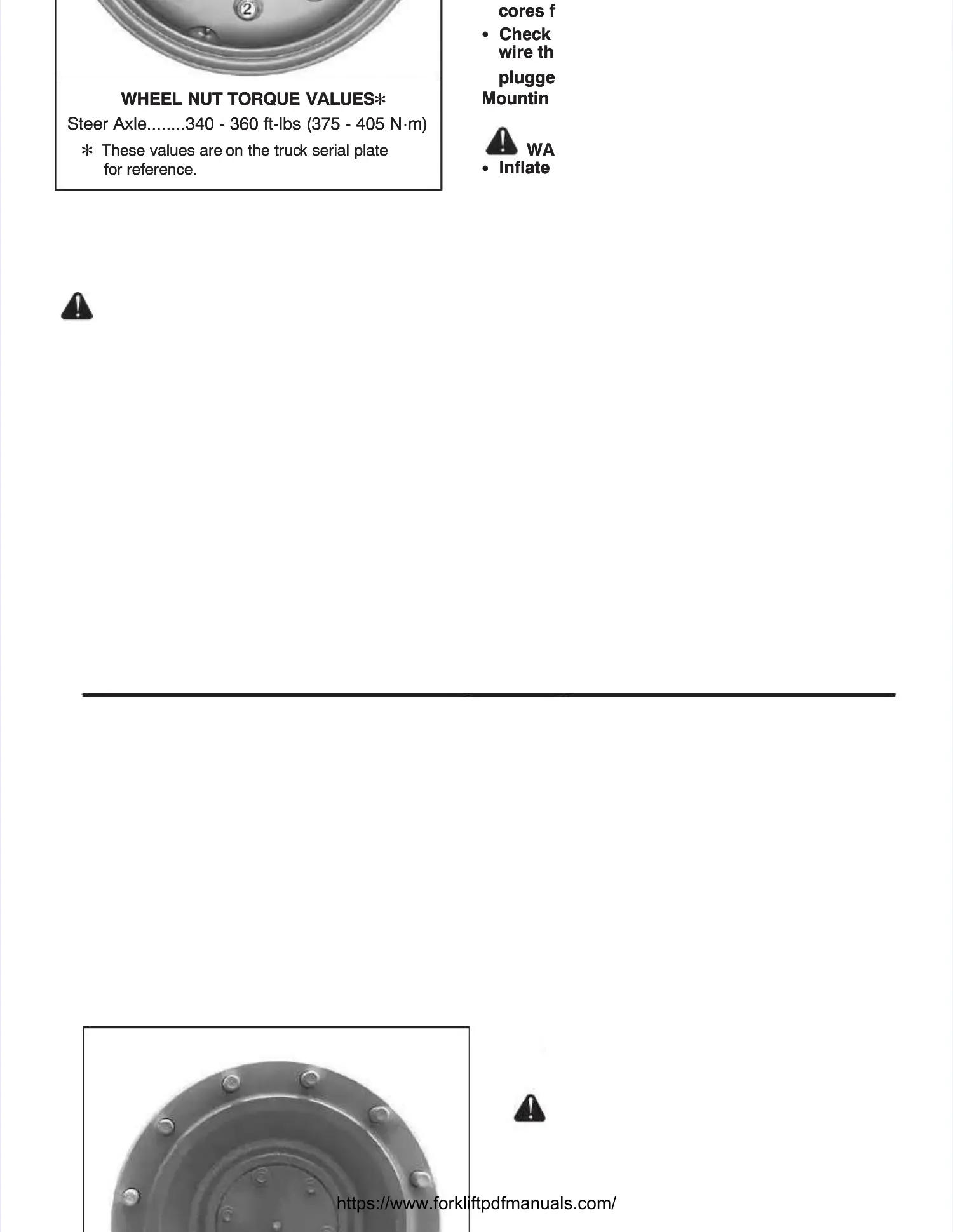

WHEEL WHEEL NUT NUT TORQUE TORQUE VALUESVALUES

Steer Axle........340 - 360 ft-lbs (375 - 405 NSteer Axle........340 - 360 ft-lbs (375 - 405 N⋅⋅m)m)

These values are These values are on the trucon the truck serial platek serial plate

for reference.for reference.

Illustration 17-3. Illustration 17-3. Steer Axle Wheel Steer Axle Wheel Nuts TNuts Torquingorquing

Sequence (TX180S-360L)Sequence (TX180S-360L)

DemountingDemounting

Do not let Do not let anyone mount anyone mount or demount or demount tirestires

without proper training as stated in OSHAwithout proper training as stated in OSHA

Rules and Regulations 1910.177 “ServicingRules and Regulations 1910.177 “Servicing

multi-piece and single piece rim wheels.”multi-piece and single piece rim wheels.”

Do not stand in Do not stand in front of the tire front of the tire duringduring

deflation.deflation.

Demounting Demounting tools apply tools apply pressure to rpressure to rimim

flanges to flanges to unseat tire unseat tire beads. beads. Keep yourKeep your

fingers clearfingers clear. . Slant the Slant the demounting demounting beadbead

cores from a dual assembly.cores from a dual assembly.

Check the valve Check the valve stem by runstem by running a pining a piece ofece of

wire through the stem to make sure it is notwire through the stem to make sure it is not

plugged.plugged.

Mounting And InflationMounting And Inflation

Inflate Inflate tire tire in in a a safety cage. safety cage. Use Use safetysafety

chains or equivalent restraining devices dur-chains or equivalent restraining devices dur-

ing inflatiing inflation. on. Misassembled Misassembled parts may parts may flyfly

apart with explosive force during inflation.apart with explosive force during inflation.

Do not Do not seat rings bseat rings by hammering y hammering while thewhile the

tire is being tire is being inflated. inflated. If a part is tapIf a part is tapped, it orped, it or

the tool can fly out with explosive force.the tool can fly out with explosive force.

Never sit on or stand Never sit on or stand in front of a tire and in front of a tire and rimrim

assembly that assembly that is being is being inflated. inflated. Use a cliUse a clip-p-

on chuck, an in-line pressure gauge, andon chuck, an in-line pressure gauge, and

make sure the inflation hose is long enoughmake sure the inflation hose is long enough

to permit the person inflating the tire toto permit the person inflating the tire to

stand to the side of the stand to the side of the tire, not in front or intire, not in front or in

back of the tire assembly.back of the tire assembly.

Mixing parts Mixing parts of one mof one manufacturer’s rims anufacturer’s rims withwith

those of another is those of another is potentially dangerous.potentially dangerous.

Always check manufacturer for approval.Always check manufacturer for approval.

Do Do not bnot be careless e careless or or take chances. take chances. If youIf you

are not sure about are not sure about the proper mating of rimthe proper mating of rim

and wheel parts, consult a wheel and rimand wheel parts, consult a wheel and rim

expert. expert. This may This may be the tire be the tire man who man who isis

servicing your fleet or the rim and wheel dis-servicing your fleet or the rim and wheel dis-

tributor in your area.tributor in your area.

Do not inflate Do not inflate the tire before all the tire before all side and lockside and lock

rings are rings are in place. in place. Double check Double check to maketo make

sure all components are properly seated.sure all components are properly seated.

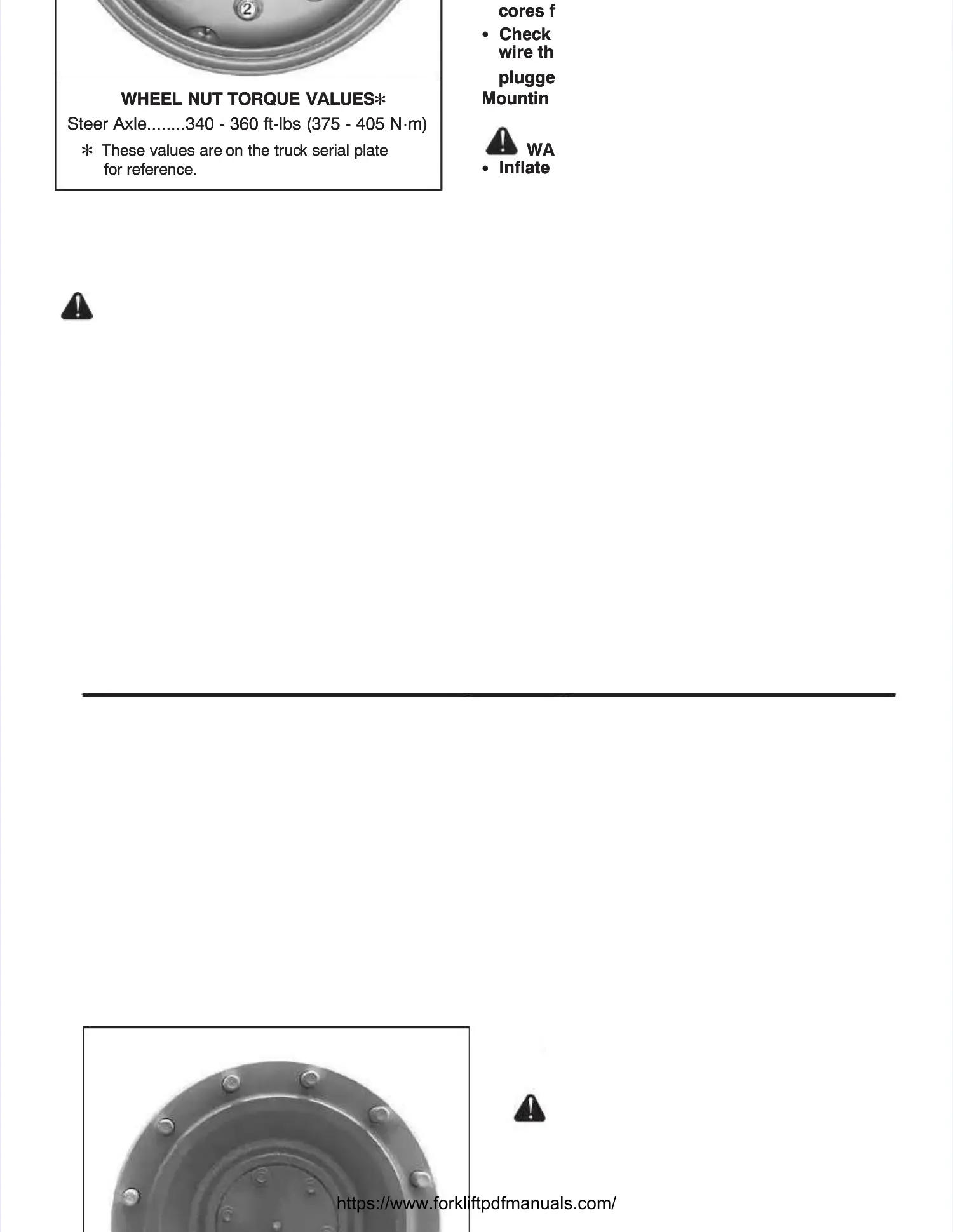

1.1. Refer Refer to Ito Illustllustration ration 17-5 17-5 for for hardwhardware aare and ind itsts

orientation for wheel mounting.orientation for wheel mounting.

2.2. CheCheck cock compomponennents fots for propr proper asser assembembly agaly againin

after inflating to approximately 5 psi (.3 bar).after inflating to approximately 5 psi (.3 bar).

1212

11

33

55

88

99

mended rim for the tire.mended rim for the tire.

Never run a vehiNever run a vehicle on one tircle on one tire of a duale of a dual

assembly. assembly. The carryinThe carrying capacity g capacity of theof the

single tire and rim is dangerously exceededsingle tire and rim is dangerously exceeded

and operating a vehicle in this manner canand operating a vehicle in this manner can

result in damage to the rim and tire.result in damage to the rim and tire.

Do not reiDo not reinflate a tire that nflate a tire that has been run has been run flatflat

without first inspecting the tire, rim andwithout first inspecting the tire, rim and

wheel assembly. wheel assembly. Double check Double check the lock the lock ringring

for damage; make sure that it is secure infor damage; make sure that it is secure in

the gutter before inflation.the gutter before inflation.

Excessive turning Excessive turning of the steeriof the steering axle tirng axle tires,es,

when the truck is stopped, should bewhen the truck is stopped, should be

avoided. avoided. It can It can cause excessive cause excessive wear (flatwear (flat

spots) to develop.spots) to develop.

Servicing Tire And Rim On VehicleServicing Tire And Rim On Vehicle

Block the Block the other tires oother tires of the vehicle f the vehicle beforebefore

you place the jack in position.you place the jack in position.

Regardless of hRegardless of how hard or ow hard or firm the grofirm the groundund

appears, put hardwood blocks under theappears, put hardwood blocks under the

jack. jack. Always crib Always crib up vehicle wiup vehicle with blocks juth blocks justst

in case the jack should slip.in case the jack should slip.

Loading...

Loading...