TX / TXH / TXB 180S - 400L (Rev. 4/23/07)TX / TXH / TXB 180S - 400L (Rev. 4/23/07)

22-822-8

PARKINPARKING G BRAKEBRAKE

ACCUMULAACCUMULATOR PRE-TOR PRE-

CHARGED TO 500 PSICHARGED TO 500 PSI

(1/2 GALLON)(1/2 GALLON)

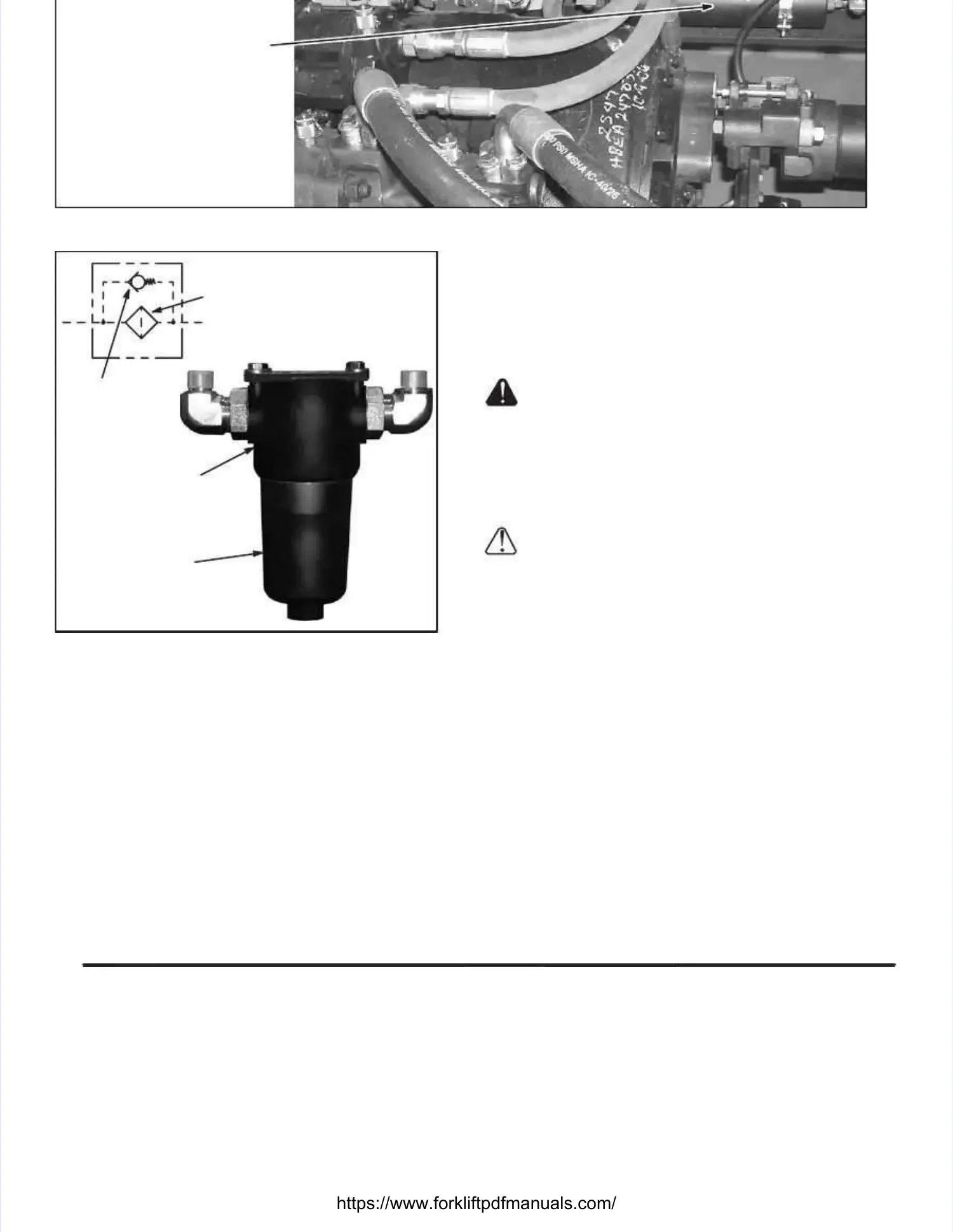

Illustration Illustration 22-12. 22-12. AccumulatorsAccumulators

RETURNRETURN

FILTERFILTER

ELEMENTELEMENT

50 PSI50 PSI

(3.5 bar)(3.5 bar)

BYPASSBYPASS

FILTERFILTER

BOWLBOWL

FILTERFILTER

HEADHEAD

Illustration Illustration 22-13. 22-13. Pilot Pilot FilterFilter

Pilot Filter ReplacementPilot Filter Replacement (Illustration 22-13)(Illustration 22-13).. TheThe

pilot filter pilot filter filters the filters the pilot pressure fpilot pressure fluid. luid. The filterThe filter

head contains a head contains a 50 psi (3.5 50 psi (3.5 bar) bypass. bar) bypass. When aWhen a

pressure differential exists of greater than 50 psipressure differential exists of greater than 50 psi

through the filter element, the bypass will openthrough the filter element, the bypass will open

and unfiltered pilot fluid will enter the pilot pas-and unfiltered pilot fluid will enter the pilot pas-

sages of tsages of the main valve. he main valve. The pilot filter The pilot filter should beshould be

replaced periodically (refer to thereplaced periodically (refer to the PreventivePreventive

MaintenanceMaintenance chart in thechart in the AppendicesAppendicesfor pilotfor pilot

filter replacement filter replacement interval). interval). Perform the Perform the followingfollowing

procedures to replace the pilot filter:procedures to replace the pilot filter:

Death or serious injury couldDeath or serious injury could

result from result from a runaway truck. a runaway truck. Park the truck Park the truck onon

a hard, level surface, apply the parking brake,a hard, level surface, apply the parking brake,

block the wheels in both directions to preventblock the wheels in both directions to prevent

movement of the truck and Lock Out movement of the truck and Lock Out & Tag Out& Tag Out

the truck.the truck.

Dispose of fluid and filter inDispose of fluid and filter in

accordance with federal and local regulations.accordance with federal and local regulations.

1.1. Park tPark the trhe truck on a hauck on a hard, lerd, level svel surfurfaceace, blo, blockck

the wheels in both directions, apply the park-the wheels in both directions, apply the park-

ing brake and Lock Out & Tag Out the truck.ing brake and Lock Out & Tag Out the truck.

2.2. EnsEnsure fure filtilter is cer is cool tool to the to the toucouch and ph and provrovide aide a

suitable container to catch any draining fluid.suitable container to catch any draining fluid.

3.3. Drain Drain the fthe filter ilter bowl bowl if eif equipped quipped with with drain drain bolt.bolt.

4.4. LoosLoosen en and and remremove ove filfilter ter bowbowl.l.

5.5. RemovRemove file filter ter by puby pulling lling downwdownward ward with a ith a slighslightt

twisting motion. twisting motion. Discard properly Discard properly of filterof filter..

6.6. CheCheck bock bowl O-wl O-rinring for dg for damaamage ange and repld replace iace iff

necessary.necessary.

7.7. LubricLubricate tate the O-rhe O-ring oing of thf the new e new filtefilter witr with clh cleanean

hydraulic fluid. hydraulic fluid. Place new Place new filter on post filter on post in filterin filter

head.head.

8.8. InstaInstall fill filter lter bowl bowl and tand tighten ighten to a to a torque torque valuevalue

of 15-20 ft-lbs (20-27 Nof 15-20 ft-lbs (20-27 N⋅⋅m).m).

99 EnsEnsure fure filtilter is cer is cool tool to the to the toucouch and prh and proviovide ade a

vent hydraulic vent hydraulic fluid aeration. fluid aeration. Refer to Refer to thethe ServiceService

CapacitiesCapacities in thein the AppendicesAppendices for the workingfor the working

and total refill capacities of the hydraulic tank.and total refill capacities of the hydraulic tank.

Temperature Switch.Temperature Switch. When the temperature ofWhen the temperature of

the fluid in the hydraulic tank exceeds 180the fluid in the hydraulic tank exceeds 180

FF

(82(82

C), a normally closed (NC) switch will open.C), a normally closed (NC) switch will open.

This will signal the TICS (TThis will signal the TICS (Taylor Integrated aylor Integrated ControlControl

System) of a high hydraulic fluid temperature con-System) of a high hydraulic fluid temperature con-

dition. dition. A High HA High Hydraulic Tydraulic Temperature activeemperature active

warning will appear on the TICS display module.warning will appear on the TICS display module.

Loading...

Loading...