22-922-9TX / TXH / TXB 180S - 400L (Rev. 4/23/07)TX / TXH / TXB 180S - 400L (Rev. 4/23/07)

9.9. EnsEnsure fure filtilter is cer is cool tool to the to the toucouch and prh and proviovide ade a

suitable container to catch any draining fluid.suitable container to catch any draining fluid.

10.10. Apply an even Apply an even film of film of fresh hydraulic fluid fresh hydraulic fluid onon

the gasket surface of the replacement filter.the gasket surface of the replacement filter.

11.11. Unscrew filter Unscrew filter and dispose of properlyand dispose of properly..

12.12. Thread the new Thread the new filter onto filter onto filter head.filter head.

13.13. Hand tighten fHand tighten filter 3/4 tilter 3/4 turn past point urn past point wherewhere

gasket first contacts filter head surface.gasket first contacts filter head surface.

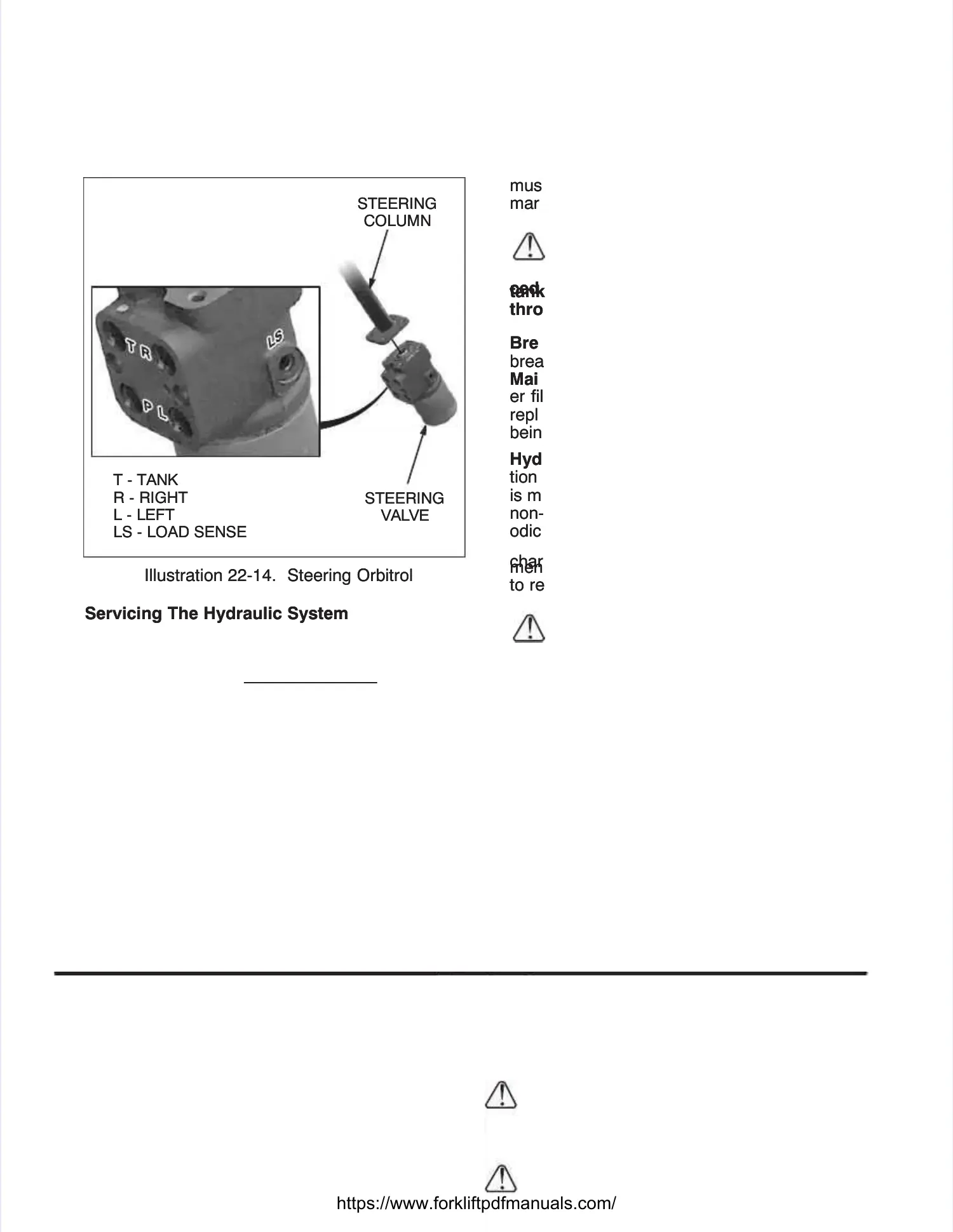

STEERINGSTEERING

VALVEVALVE

STEERINGSTEERING

COLUMNCOLUMN

T - TANKT - TANK

R - RIGHTR - RIGHT

L - LEFTL - LEFT

LS - LOAD SENSELS - LOAD SENSE

Illustration Illustration 22-14. 22-14. Steering Steering OrbitrolOrbitrol

Servicing The Hydraulic SystemServicing The Hydraulic System

Hydraulic Operation.Hydraulic Operation. All All hydraulic hydraulic functionsfunctions

should be checked daily for free operation [refer toshould be checked daily for free operation [refer to

Daily ChecksDaily Checks in the Operator’s Guide (OG160)].in the Operator’s Guide (OG160)].

Hydraulic TankHydraulic Tank (Illustration 22-16)(Illustration 22-16).. The The tank tank isis

equipped with a return fequipped with a return filterilter. . All air entering All air entering thethe

tank is filtered through a disposable breather.tank is filtered through a disposable breather.

This tank also contains a diffuser which helps pre-This tank also contains a diffuser which helps pre-

Checking The Fluid LevelChecking The Fluid Level (Illustration 22-15)(Illustration 22-15)..

The hydraulic fluid level can be checked on theThe hydraulic fluid level can be checked on the

fluid level dipstfluid level dipstick. ick. Ensure the cEnsure the carriage is fullyarriage is fully

lowered and the mast is fully tilted back beforelowered and the mast is fully tilted back before

checking the checking the hydraulic fluid hydraulic fluid level. level. Refer to Refer to thethe

Fuel and Lubricant SpecificationsFuel and Lubricant Specificationsin thein the

AppendicesAppendicesfor the type of fluid to be used.for the type of fluid to be used.

Add hydraulic fluid unAdd hydraulic fluid until the fluid level til the fluid level is even withis even with

the FULL mthe FULL mark on the ark on the dipstick. dipstick. The fluid levThe fluid levelel

must be maintained between the FULL and ADDmust be maintained between the FULL and ADD

marks on the dipstick.marks on the dipstick.

Not adhering to the above pro-Not adhering to the above pro-

cedure can lead to overfilling of the hydrauliccedure can lead to overfilling of the hydraulic

tank. tank. As a result, As a result, hydraulic fluid hydraulic fluid will be forwill be forcedced

through the through the breatherbreather..

Breather FilterBreather Filter(Illustration 22-16)(Illustration 22-16).. Replace Replace thethe

breather filter periodically (refer to thebreather filter periodically (refer to the PreventivePreventive

MaintenanceMaintenancechart in thechart in the AppendicesAppendicesfor breath-for breath-

er filter er filter replacement intreplacement interval). erval). More frequentMore frequent

replacement may be necessary if the machine isreplacement may be necessary if the machine is

being operated under extremely dusty conditions.being operated under extremely dusty conditions.

Hydraulic Return Filter ReplacementHydraulic Return Filter Replacement (Illustra-(Illustra-

tions 22-15 and 22-16)tions 22-15 and 22-16).. The The hydraulic hydraulic return return filterfilter

is made up of 10 micron glass fiber media and isis made up of 10 micron glass fiber media and is

non-reusable. non-reusable. This filter This filter should be should be replaced peri-replaced peri-

odically (refer to theodically (refer to the Preventive MaintenancePreventive Maintenance

chart in thechart in the AppendicesAppendicesfor return filter replace-for return filter replace-

ment intervment interval). al). Perform the Perform the following procfollowing proceduresedures

to replace the hydraulic return filter:to replace the hydraulic return filter:

Used return hydraulic filtersUsed return hydraulic filters

should be disposed of according to federalshould be disposed of according to federal

and local regulations.and local regulations.

1.1. LoLoososen en ththe 6 be 6 bololtsts..

2.2. TTwist wist the the cover cover countcounterclocerclockwise kwise and land lift ift toto

remove cover.remove cover.

3.3. RemRemove rove retueturn frn filtilter aer assessemblmblyy..

4.4. ReRemomove rve retetururn fin filtlterer..

5.5. InspecInspect tt the he grommegrommet ft for sor serviceerviceable able conditconditionion

and replace if necessary.and replace if necessary.

6.6. InInststalall nl new ew fifiltlterer..

7.7. PlacPlace cove cover over over boler bolts unts until ctil coveover sear seatsts

against head against head and twist and twist cover clockwcover clockwise. ise. Tight-Tight-

en bolts to a torque value of 10-12 ft-lbsen bolts to a torque value of 10-12 ft-lbs

(14-16 N(14-16 N⋅⋅m)m)

the truck.the truck.

Dispose of drained hydraulicDispose of drained hydraulic

fluid in accordance with federal and localfluid in accordance with federal and local

regulations.regulations.

The lift and tilt cylindersThe lift and tilt cylinders

should be fully retracted to keep dilution of theshould be fully retracted to keep dilution of the

new hydraulic fluid to new hydraulic fluid to a minimum.a minimum.

Loading...

Loading...