27-127-1TX / TXH / TXB 180S - 400L (Rev. 4/23/07)TX / TXH / TXB 180S - 400L (Rev. 4/23/07)

serious failure of the structural weldment.serious failure of the structural weldment.

When a crack is found, the truck must beWhen a crack is found, the truck must be

immediately taken out of service and repaired.immediately taken out of service and repaired.

Under no circumstances,Under no circumstances,

without prior written approval without prior written approval from Taylorfrom Taylor

Machine Works, Inc. Engineering Department,Machine Works, Inc. Engineering Department,

should the should the mast assembly mast assembly be modifibe modified. ed. As perAs per

OSHA 29 CFR1910.178 (a) (4).OSHA 29 CFR1910.178 (a) (4).

If the fatigue crack is allowedIf the fatigue crack is allowed

to grow, catastrophic failure could occur in to grow, catastrophic failure could occur in thethe

mast assembly or other welded componentsmast assembly or other welded components

causing serious injury to personnel and / orcausing serious injury to personnel and / or

property.property.

taken apart from the outer mast.taken apart from the outer mast.

The roller assemblies must notThe roller assemblies must not

be over be over lubricated. lubricated. Excess grease Excess grease inside theinside the

mast rails may cause the rollers to slide whenmast rails may cause the rollers to slide when

subjected to a subjected to a heavy load. heavy load. If this happenIf this happens, as, a

flat spot will be worn on the rollers and theflat spot will be worn on the rollers and the

rollers will continue to slide until replaced withrollers will continue to slide until replaced with

new rollers.new rollers.

Chain RollersChain Rollers (Illustration 27-4)(Illustration 27-4).. The chain rollersThe chain rollers

use sealed ball beariuse sealed ball bearings. ngs. Check the chain Check the chain rollersrollers

for looseness, cracks or flat spots.for looseness, cracks or flat spots.

Lift Chains.Lift Chains. The lift The lift chains must chains must be lubricatedbe lubricated

every 500 hours of operation (refer toevery 500 hours of operation (refer to Leaf ChainLeaf Chain

PROCEDURE 1PROCEDURE 1

PROCEDURE 2PROCEDURE 2

PROCEDURE 3PROCEDURE 3

PROCEDURE 4PROCEDURE 4

PROCEDURE 5PROCEDURE 5

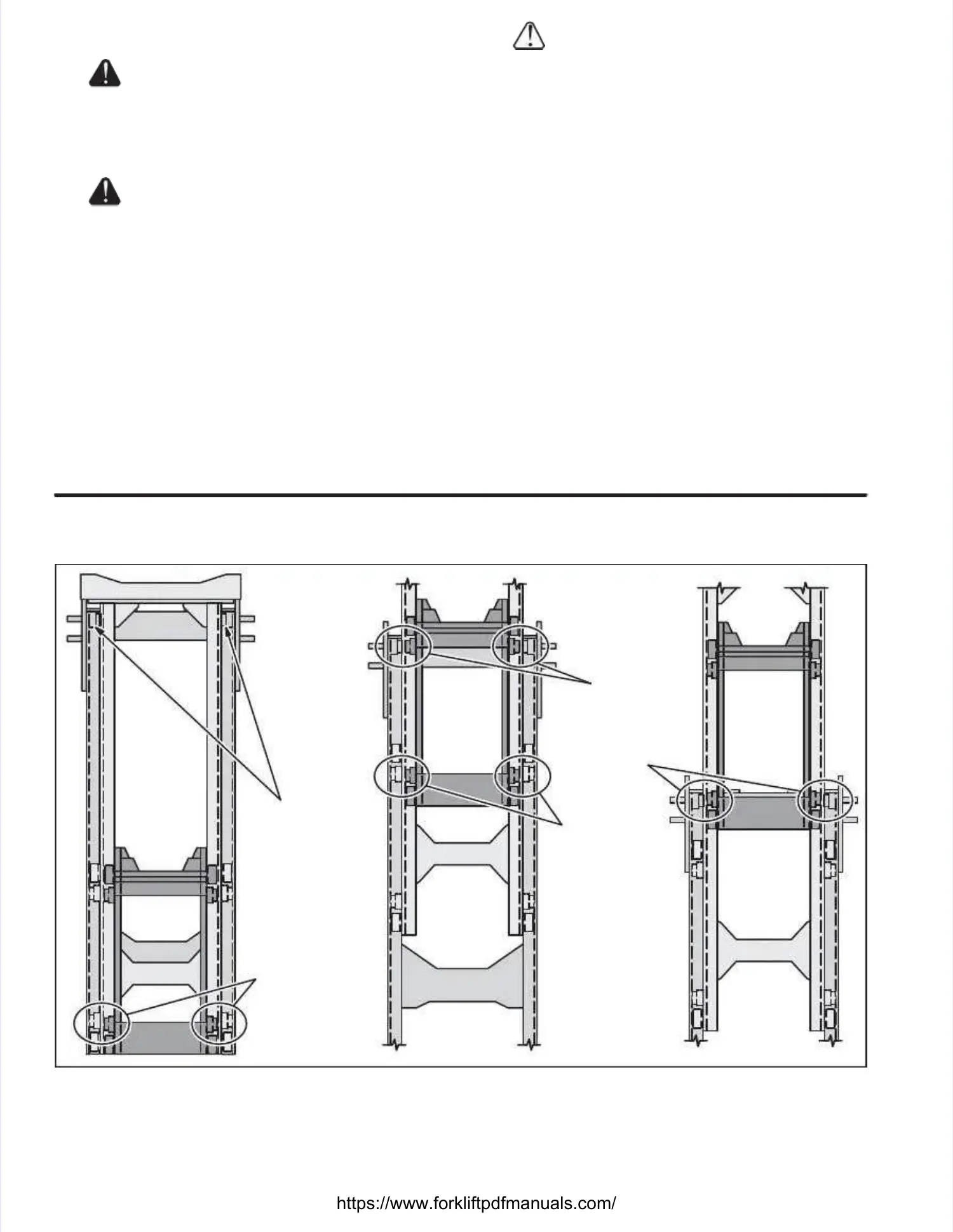

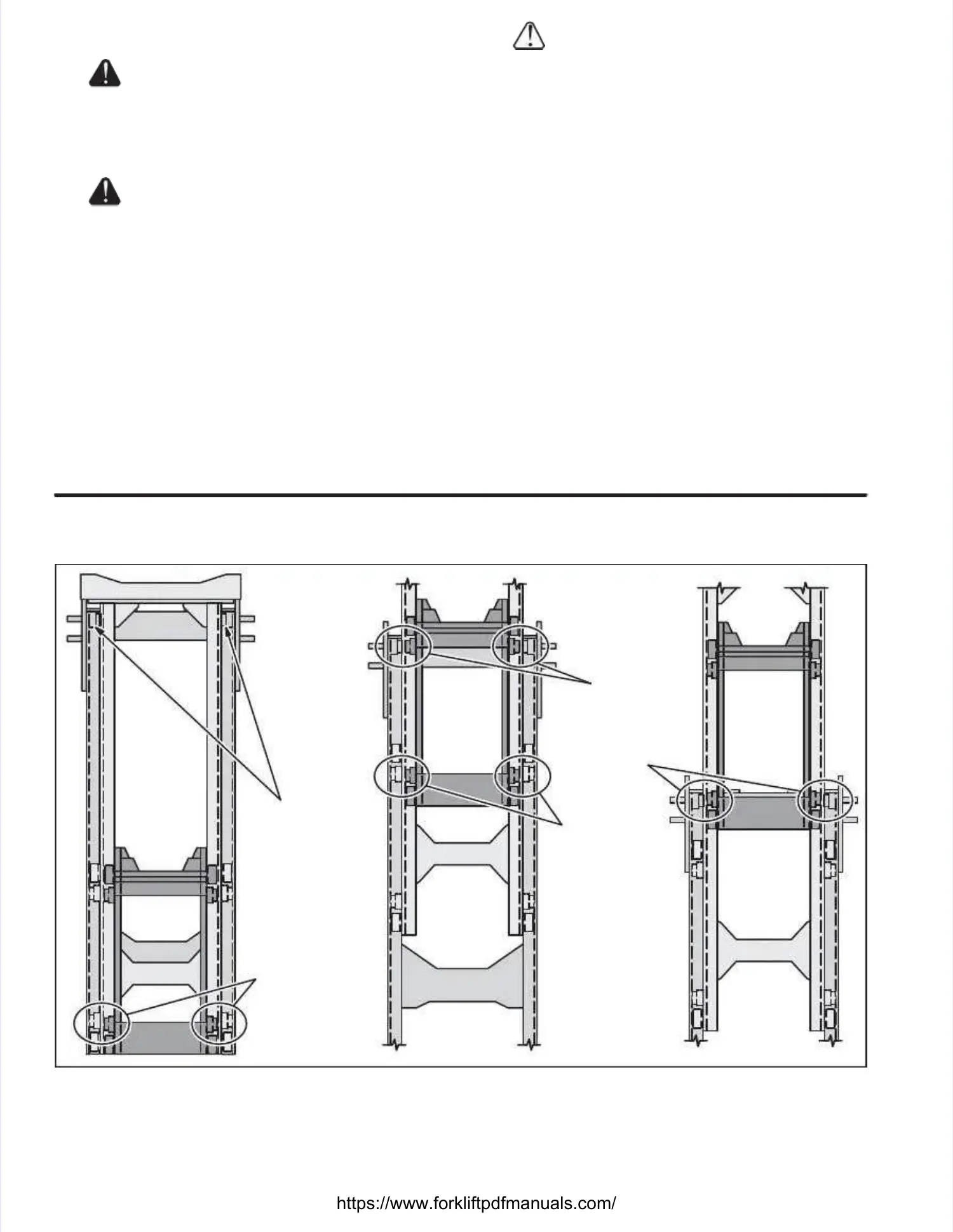

Illustration 27-1. Illustration 27-1. Mast Slide Mast Slide Bearing Shimming Bearing Shimming ProcedureProcedure

Care, Maintenance, and ReplacementCare, Maintenance, and Replacementsection insection in

the back the back of this of this manual). manual). Refer to Refer to thethe Fuel andFuel and

Lubricant SpecificationsLubricant Specificationsfor the type of lubricantfor the type of lubricant

to be used to lubricate the lift chains.to be used to lubricate the lift chains.

Tilt Cylinder and Mast Hanger Pins.Tilt Cylinder and Mast Hanger Pins. The The tilt tilt cyl-cyl-

inder and mast hanger pins must be greased peri-inder and mast hanger pins must be greased peri-

odically (refer to theodically (refer to the Preventive MaintenancePreventive Maintenance

install shims in the outer mast slide bearings.install shims in the outer mast slide bearings.

The carriage and inner mast should then beThe carriage and inner mast should then be

secured in position by an appropriate meanssecured in position by an appropriate means

or they can be lowered to a height where theyor they can be lowered to a height where they

can more easily be blocked in position andcan more easily be blocked in position and

shimmed. shimmed. Shim the outer Shim the outer mast until mast until the clear-the clear-

ance is 1/16 toance is 1/16 to 1/32 inch (1.6 t1/32 inch (1.6 to .8 mm).o .8 mm). (See(See

Loading...

Loading...