TX / TXH / TXB 180S - 400L (Rev. 4/23/07)TX / TXH / TXB 180S - 400L (Rev. 4/23/07)

28-228-2

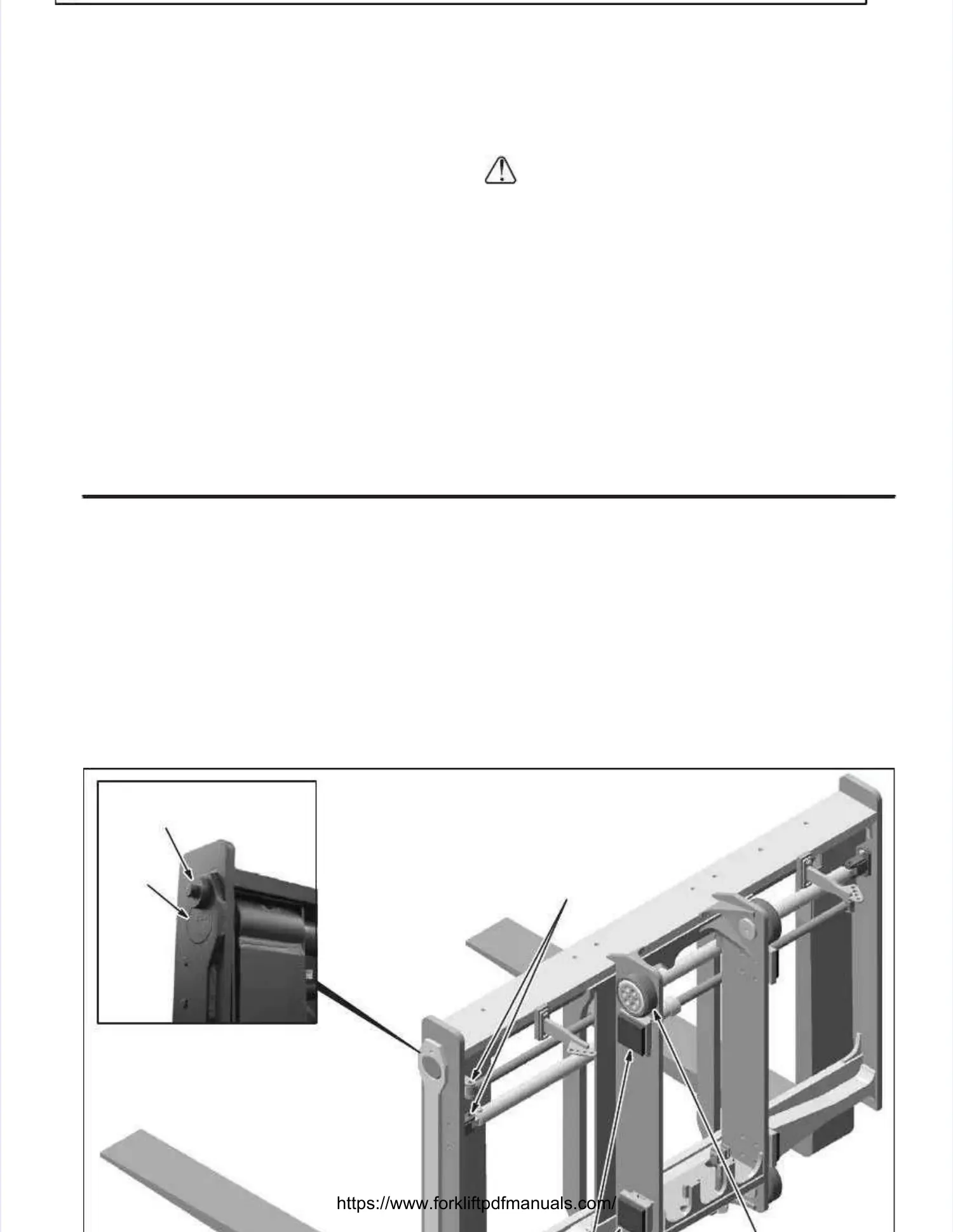

Illustration 28-2. Illustration 28-2. Optional Carriage With Side Optional Carriage With Side Shift and Fork Shift and Fork PositionersPositioners

Maintenance / Inspection.Maintenance / Inspection. There are severalThere are several

inspectional requirements which must be per-inspectional requirements which must be per-

formed dailyformed daily. . These inspections These inspections must includemust include

checking all welds and structural members forchecking all welds and structural members for

cracks. cracks. Check all Check all carriage mounting carriage mounting hardware forhardware for

damage or damage or loose bolts. loose bolts. The hydraulic The hydraulic fork posi-fork posi-

tioner cylinders and hydraulic hoses should betioner cylinders and hydraulic hoses should be

checked for leaks and functional operation.checked for leaks and functional operation.

Main RollersMain Rollers(Illustrations 28-1 through 28-3)(Illustrations 28-1 through 28-3)..

The main rollers employ greaseable, shielded,The main rollers employ greaseable, shielded,

tapered roller btapered roller bearings for iearings for increased durabilincreased durabilityty. . TheThe

main rollers must be greased periodically (refer tomain rollers must be greased periodically (refer to

thethe Preventive MaintenancePreventive Maintenancechart in thechart in the Appen-Appen-

dicesdicesfor the for the main rollers lubricmain rollers lubrication interval). ation interval). TheThe

grease fittings for the main rollers can be found ongrease fittings for the main rollers can be found on

the inside of the inside of the carriage plate. the carriage plate. The main rollersThe main rollers

should be inspected for flat spots or evidence ofshould be inspected for flat spots or evidence of

sliding any time the carriage is taken out of thesliding any time the carriage is taken out of the

inner mast.inner mast.

The roller assemblies must notThe roller assemblies must not

be over be over lubricated. lubricated. Excess grease iExcess grease inside thenside the

mast rails may cause the rollers to slide whenmast rails may cause the rollers to slide when

subjected to a subjected to a heavy load. heavy load. If this happens, If this happens, aa

flat spot will be worn on the rollers and theflat spot will be worn on the rollers and the

rollers will continue to slide until replaced withrollers will continue to slide until replaced with

new rollers.new rollers.

Slide Bearing BlocksSlide Bearing Blocks(Illustrations 28-1 through(Illustrations 28-1 through

28-3)28-3).. The slide The slide bearing block bearing block life depends life depends on theon the

duty cycle and duty cycle and operation of the operation of the truck. truck. Periodically,Periodically,

the slide bearing blocks will require shimming tothe slide bearing blocks will require shimming to

adjust for wearadjust for wear. . It is essentIt is essential for all slide ial for all slide bearingsbearings

to be to be properly shimmed. properly shimmed. For proper For proper shimmingshimming

procedures refer toprocedures refer to Section 27Section 27..

Forks.Forks. The forks must be inspected daily toThe forks must be inspected daily to

assure proper assure proper carriage operation. carriage operation. Forks must Forks must bebe

magnetic particle tested (magnafluxed) annually tomagnetic particle tested (magnafluxed) annually to

check for cracks (refer to thecheck for cracks (refer to the Fork Inspection,Fork Inspection,

Repair, and TestingRepair, and Testingin thein the AppendicesAppendices).).

Carriage.Carriage. The carriage’The carriage’s welds s welds and structuraland structural

members must be checked for cracks (refer to themembers must be checked for cracks (refer to the

Structural Inspection, Reporting, and RepairStructural Inspection, Reporting, and Repair

ProcedureProcedureat the front of this section).at the front of this section).

Lubrication.Lubrication. Refer to theRefer to the LubricationLubricationsection insection in

thethe AppendicesAppendicesfor information on the lubricationfor information on the lubrication

of the carriage.of the carriage.

CYLINDERCYLINDER

PINSPINS

FORKFORK

PIN CAPPIN CAP

FORKFORK

PINPIN

Loading...

Loading...