IM-4055

Installation, Operation & Maintenance Manual

12

2. Connect the motor to the appropriate speed control option. The motor can accommodate 1 of 2 methods for speed control.

Connect the Speed Control Potentiometer to the motor control

as follows:

(Analog Input)

Use only Copper Wire for all wiring.

Connect the Control Signal Harness to the motor control as

follows:

Use only Copper Wire for all wiring.

It is the responsibility of the installer/controls engineer to ensure that any eld

supplied controls are compatible and functional with this motor technology. TCF

is not responsible for eld supplied or customer designed fan or motor controls.

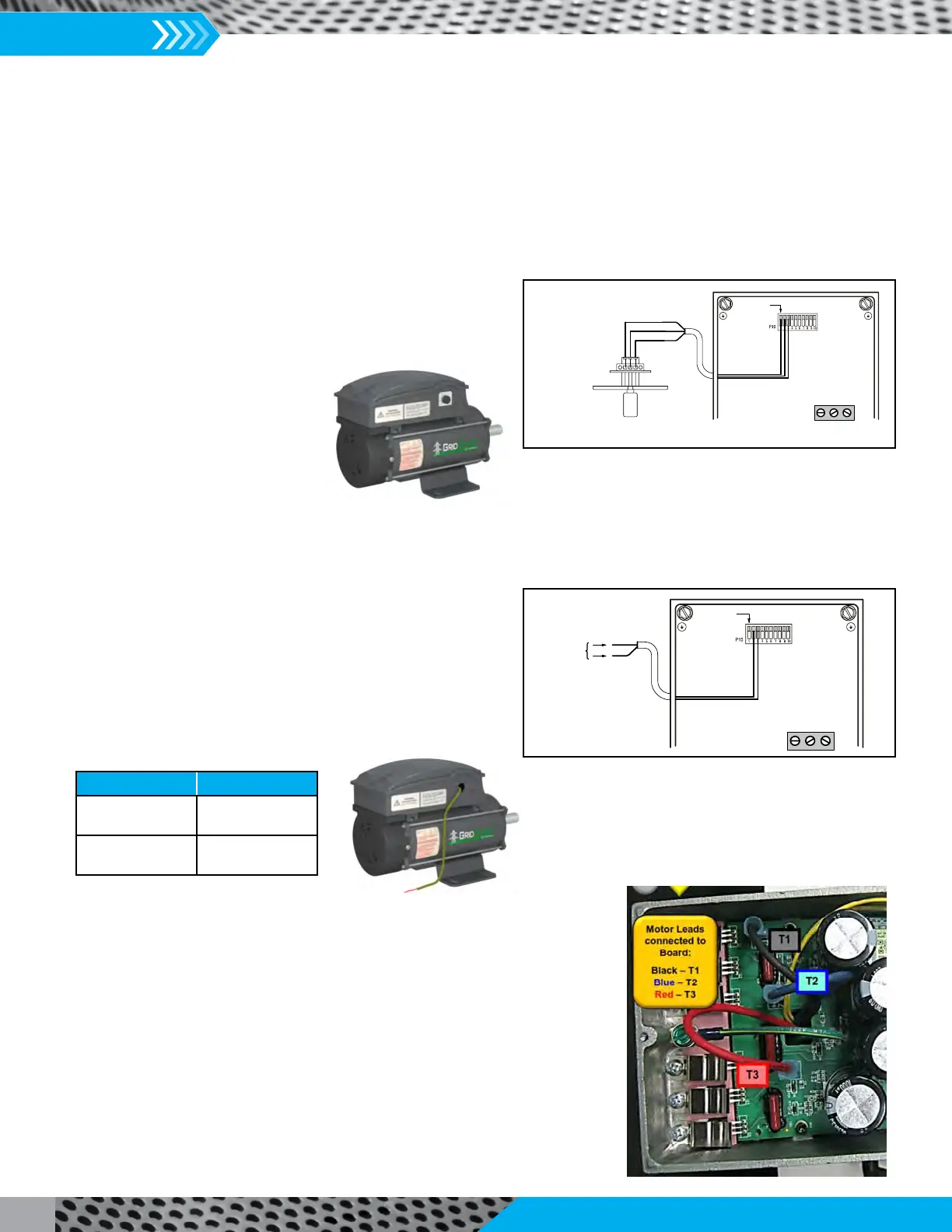

3. Verify rotation of motor is correct by energizing the motor and checking that the

rotation matches the fan rotation label. This can also be done before any speed

controls are wired in by placing a jumper wire between terminals Pin 1 and Pin 2.

This will send 10 volts into the motor and cause it to run at full speed. To change

the rotation of the motor, swap the T1 (Black) and T2 (Blue) leads (as shown on

the right). Note that the motor and fan warranty are void if the motor is rotating

in the incorrect direction. Also verify that the motor speed control is functioning

properly.

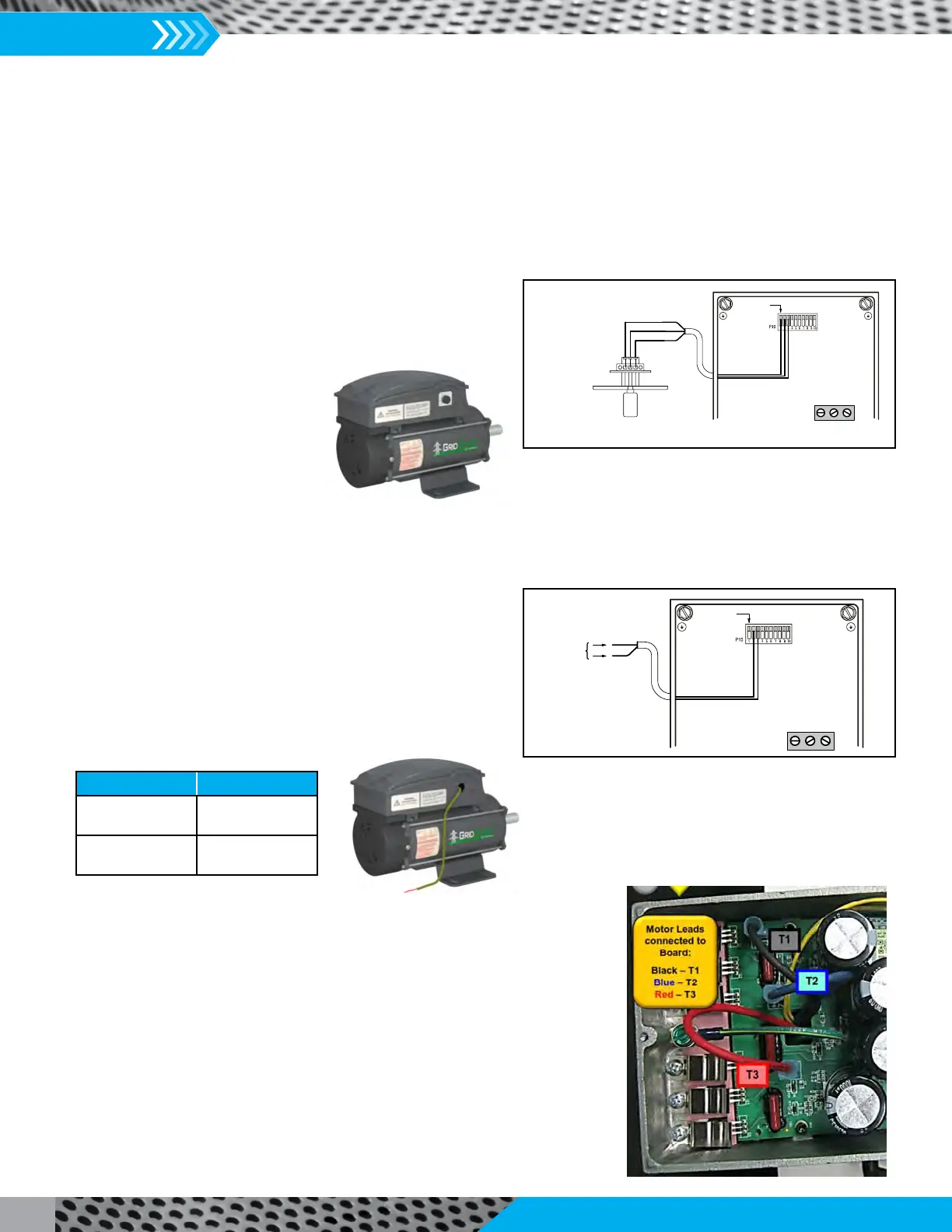

Figure 6. Motor Speed Controlled by a Remote Speed

Control Dial (Potentiometer)

P10--1

Remote Speed

ControlDial

12VDC

AnalogIn

DGND

P10

Pin1= 12VDC

Pin2=AnalogIn

Pin3=DGND

Tighten to

5--7 lb-- in

L2 L1 N

Figure 7. Motor Speed Controlled by 0-10V DC

Control Signal

P10--1

P10

Pin2= AnalogIn

Pin3= DGND

Analog Input

0--10VDC

DGND

Tightento

5--7 lb-- in

L2 L1 N

Speed Control Options: TEFC Motors (cont.)

Descripon Wire Color

0-10V DC

(Analog Input)

Red

Ground

(DGND)

White

Loading...

Loading...