2800 LAURA LANE

l MIDDLETON, WI 53562 l (800) 288-9383 l FAX (608) 836-9044 l www.tcs-basys.com

9

D12 SETPOINT SHIFT

The SZ1009, SZ1022, SZ1031 and SZ1035 allow DI2 to be

set for setpoint shift for energy demand setback. This is

enabled by setting DI2 to the MONITOR mode. A digital con-

tact that closes when setback is needed should be wired into

DI2. You may specify a number of degrees such that, when

the thermostat is operating in the occupied mode, and DI2 is

closed, the heating setpoint will be lowered this number of

degrees, and the cooling setpoint will be raised this number of

degrees. The fan will continue to operate according to its

occupied setting. If you are using DI2 as monitor for another

purpose, make sure to set this value to zero.

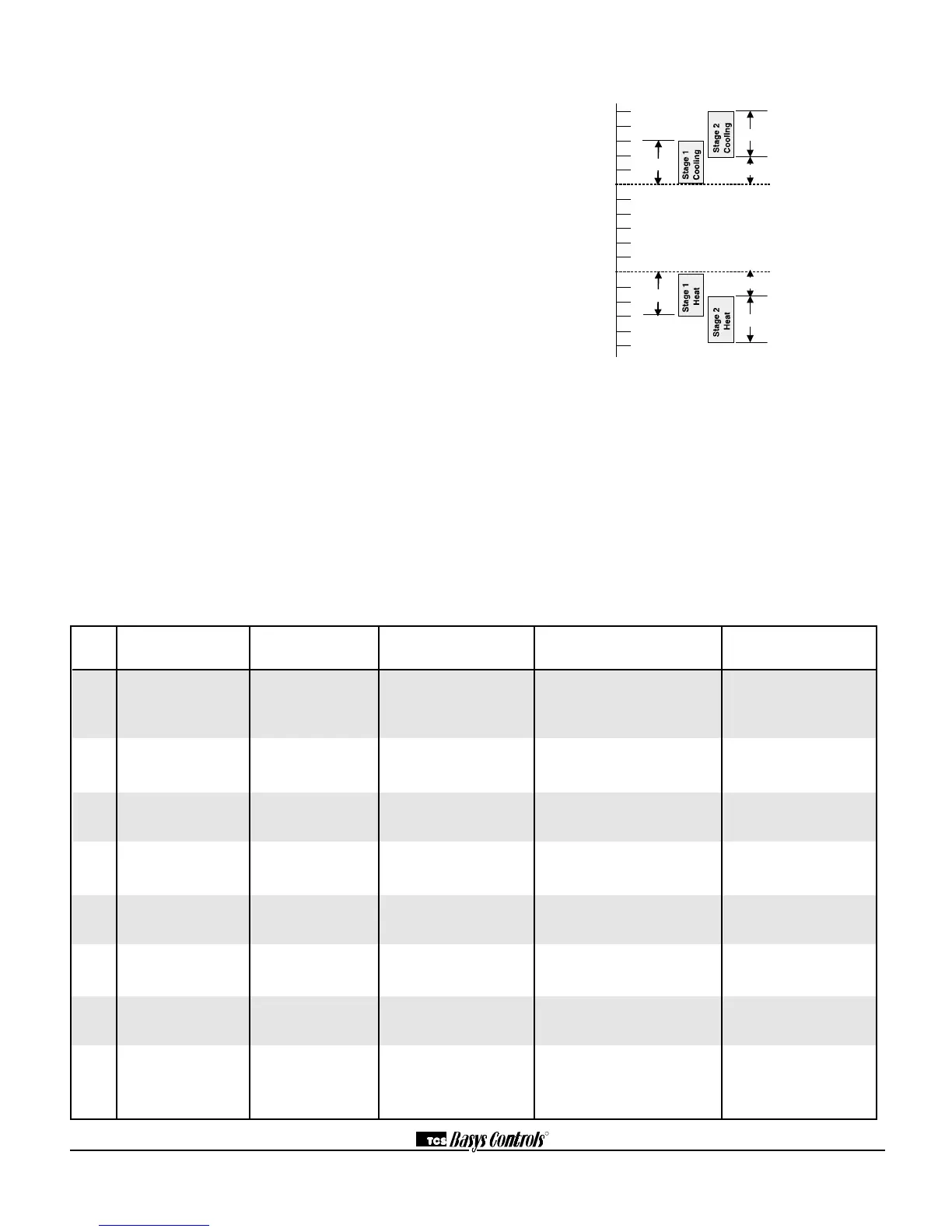

STAGE OUTPUT PARAMETERS

For each stage of heating and cooling, you may specify an off-

set and a differential value. This allows you to adjust the oper-

ation of the thermostat to fit your equipment to the building

load. The offset value is the amount away from the setpoint a

stage will turn off. By assigning a stage a value other than

zero, you “anticipate” that the residual heat or cooling in the

duct or the other stages will bring the temperature back to set-

point. In most cases, the first stage is set to zero. The differen-

tial value is the difference between the on and off points. This

value depends on the load and on the equipment size. If the

equipment is large for the load, you may want to make this

value as high as 5 to prevent equipment cycling. If the equip-

ment is small compared to the load, or if tight control is

desired, you may want to make this value as low as 1.

The fact that the stages are configurable allows unused stages

to be set to activate physical alarms if desired.

In summary, unlike most other multi-stage programmable

thermostats, the Superstat allows independent adjustments of

“offsets” and “differentials” for stages of heating and cooling.

The offset settings can be viewed as setpoints for the second

and third stages and are programmed in the Superstat in the

number of degrees (i.e. 1,2,3 ... ) beyond the heating and

cooling setpoints (temperatures to be maintained).

The differential for each stage can be viewed as the “anticipa-

tor” function used in mechanical thermostats.

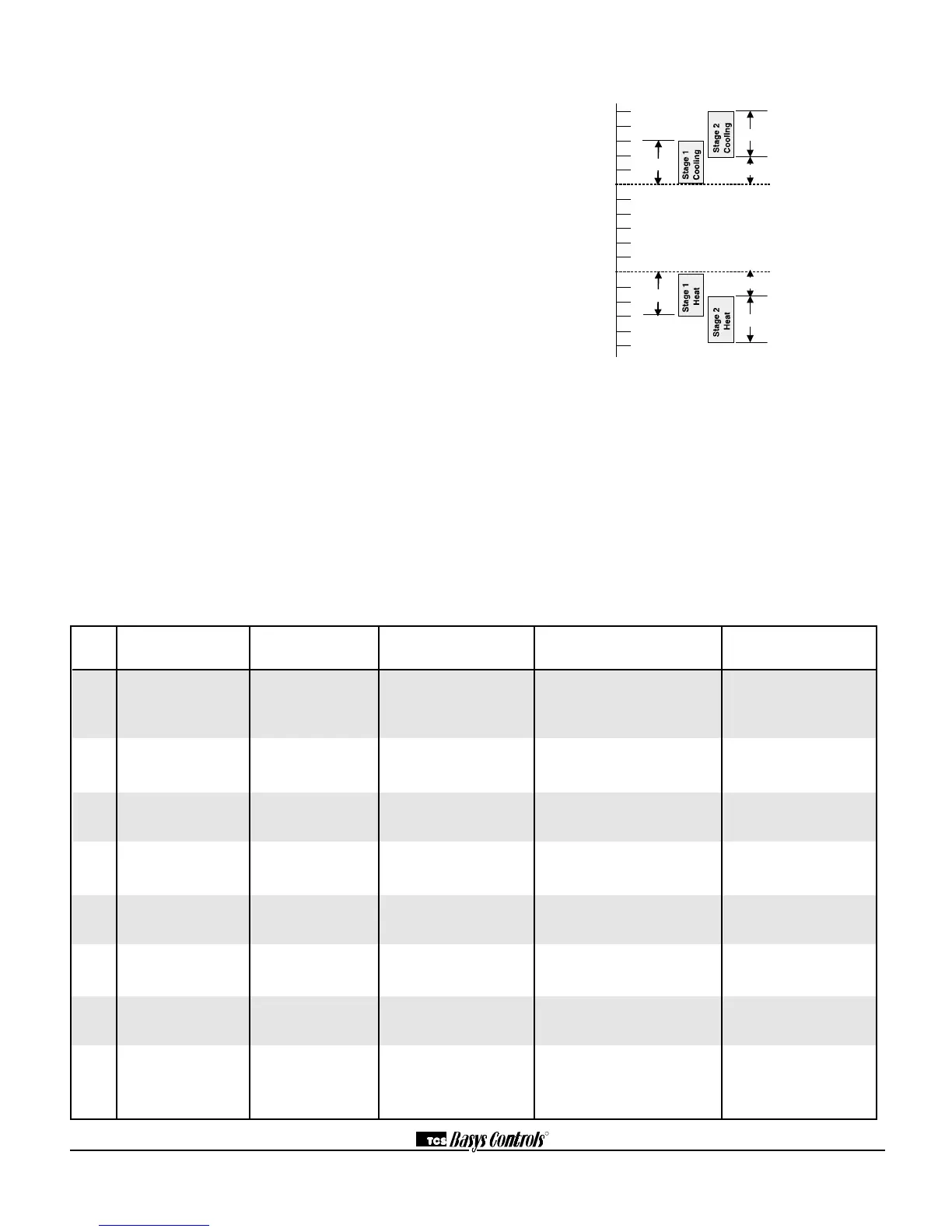

DIGITAL APPLICATION LED SERVICE SCREEN CONTROL SENSOR OR

INPUT INDICATION? (DI STATUS SCREEN) PROVIDED DEVICE NEEDED

DI1 Fan Proving YES CHECK FAN, YES - turns system mode to "off" Differential

FAN OK — requires manual re-start pressure or

or FAIL (set system to auto) current switch

DI1 Equipment NO OK NO Dry contact, switch. Any type

Monitoring (DI1 OPEN or CLOSED) for monitoring and indication

DI2 Service Alert YES OK or CHECK DI2 NO Dry contact, switch. Any type

(DI2 SERVICE OFF or ON) for monitoring and indication

DI2 Monitor with NO OK YES - shifts setpoint by Dry contact, switch.

setpoint shift (DI2 OPEN or CLOSED) programmed amount

DI2 Cooling Lockout NO OK YES - locks out 2nd Dry contact, switch.

(COOL LOCKOUT ON or OFF) and 3rd stage cooling

DI3 Filter Service YES OK or CHECK FILTER NO Differential pressure switch

(FILTER OK or CHECK)

DI3 External Occupancy Override NO OK YES - switches to occupied mode Dry contact such as twist

(EXT OVER ON or OFF) as long as contact is made timer, light switch, etc.

DI3 External Time Clock Input NO OK YES -input overrides thermostat Dry contact;

(EXT TIMECLOCK ON or OFF) occupancy program external time clock

(TCS part SL1001a)

Digital Input Summary Table

Loading...

Loading...