3290

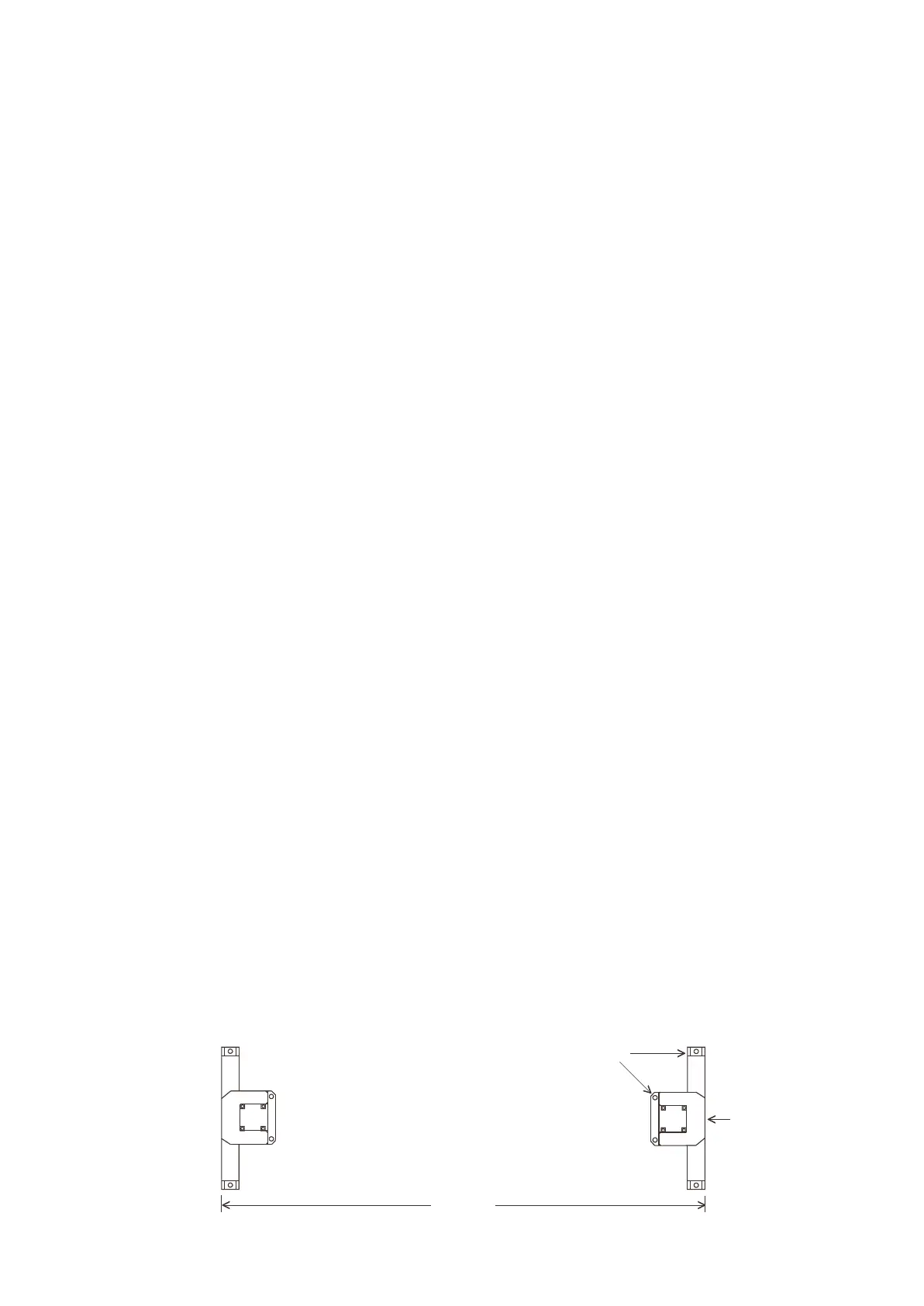

Important - Shim 8 places

Step 9

Shim 8 places

under frame

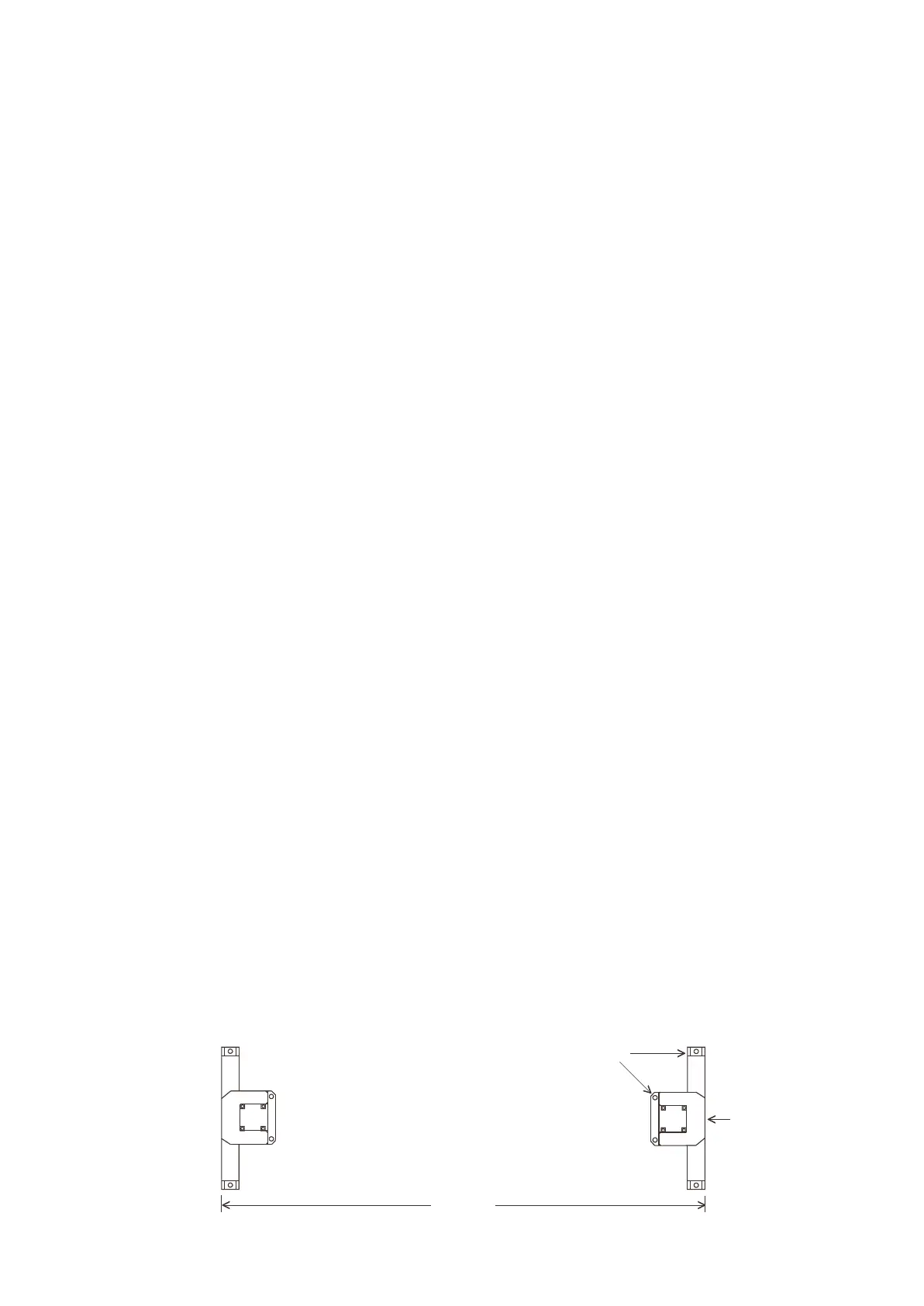

Step 11

Measure and

shim under

frame

Installation Instructions

By following these instructions carefully, your new hoist

can be assembled quickly to give safe, smooth and

efficient operation and an extended, trouble-free life.

1. The hoist must be installed under cover on a flat

concrete floor of minimum tensile strength Grade 25

MPa and minimum thickness 100 mm with at least

one layer of F72 reinforcing mesh. The hoist must

not be installed in a location where it is exposed to

the weather or explosive or flammable materials. If

the floor is not satisfactory, a new concrete base

with a minimum area of 3.7m x 1.6m will need to be

laid and allowed to cure for one month before

installing the hoist.

2. Install a mains isolator switch on a wall or column

next to where the hoist power column will be

situated. The power supply must be 415 V, 50 Hz,

rated to carry 15A full load current and 33A inrush.

The wiring must be 4 core plus earth and a minimum

7-strand, 2.5mm2 cross sectional area copper. For

long runs larger wiring may be required. The hoist

power supply must be free of voltage fluctuations

and spikes and must be protected by fuses or circuit

breakers.

Note: This must be done by a qualified electrician.

3. Unpack the hoist and place the base frames on the

floor in the desired position. (refer Fig. 1)

Check there is easy access for vehicles and a clear

600 mm wide gap around the hoist and vehicle for

operator access.

Check there is 3.9 m clearance overhead for the

hoist overhead crossbeam. Check there is sufficient

clearance overhead to prevent a collision with the

vehicle. If there is not sufficient clearance, the

installer and owner of the hoist must provide a

means of preventing a collision from occurring.

Inspect the floor where the eight hold-down bolts will

go. The hold-down bolts must not be installed within

200 mm of any edge, crack or other fastener in the

floor.

Note: Use lifting equipment or extra people to

lift and move the heavy items.

4. Stand the two columns up on the base frames. Bolt

the columns down using four M16 x 50 mm long

and four M10 x 35 mm long high tensile bolts.

Leave the M16 bolts undone about 4 mm (two

turns). Fully tighten the M10 bolts with a ring or

socket spanner, then tighten the M16 bolts fully

with a torque wrench to 200NM. (147 ft lbs)

Note: The bolts must be high tensile, identified by

the marking ‘8.8’ on the head of the bolts.

5. Attach the uprights to the back of the columns

using the M12 nuts and spring washer supplied

and fully tighten. (The upright with the limit switch

fitted goes on the drive column.)

6. Feed the wiring on the slave column up through

the upright & out the top.

Note: Check that the ends of the cables are

correctly labeled “Motor” “Proximity” and “Top Limit

Switch”.

7. Attach the overhead cross beam and trip bar

assembly to both uprights using the M6 bolts and

Nyloc nuts supplied. (This sets the correct distance

between the top of the columns).

Note: The trip bar is offset towards the drive

column end of the cross beam, So that it will operate

the limit switch on the upright.

The columns may need to be moved closer together

to allow the cross beam to reach.

Fit the M6 x 65L bolt from the bottom & fit the nut

on top to give a neat appearance. (Refer Fig. 5)

8. Move the base frames to the specified distance

apart. (Refer Fig. 1) Sight along both sides of each

column to check it is pointing towards the other

column.

9. Add shims under the base frames to set the correct

lean outwards and sideways on both columns and to

set both bases at the same height. (Shims are to be

placed at the hold down bolt holes). (Refer Fig. 1)

Measure the lean on the drive column and the

slave column using a plumb line. Each column

should lean outwards between 5 and 11 mm from

top to bottom. Sideways lean should be a

maximum of 5 mm off vertical.

Recheck the distance between the columns and the

squareness of the columns.

Page 4

Loading...

Loading...