Slave proximity

Slave top

limit switch

Drive upright

limit switch

Slave motorPower supply

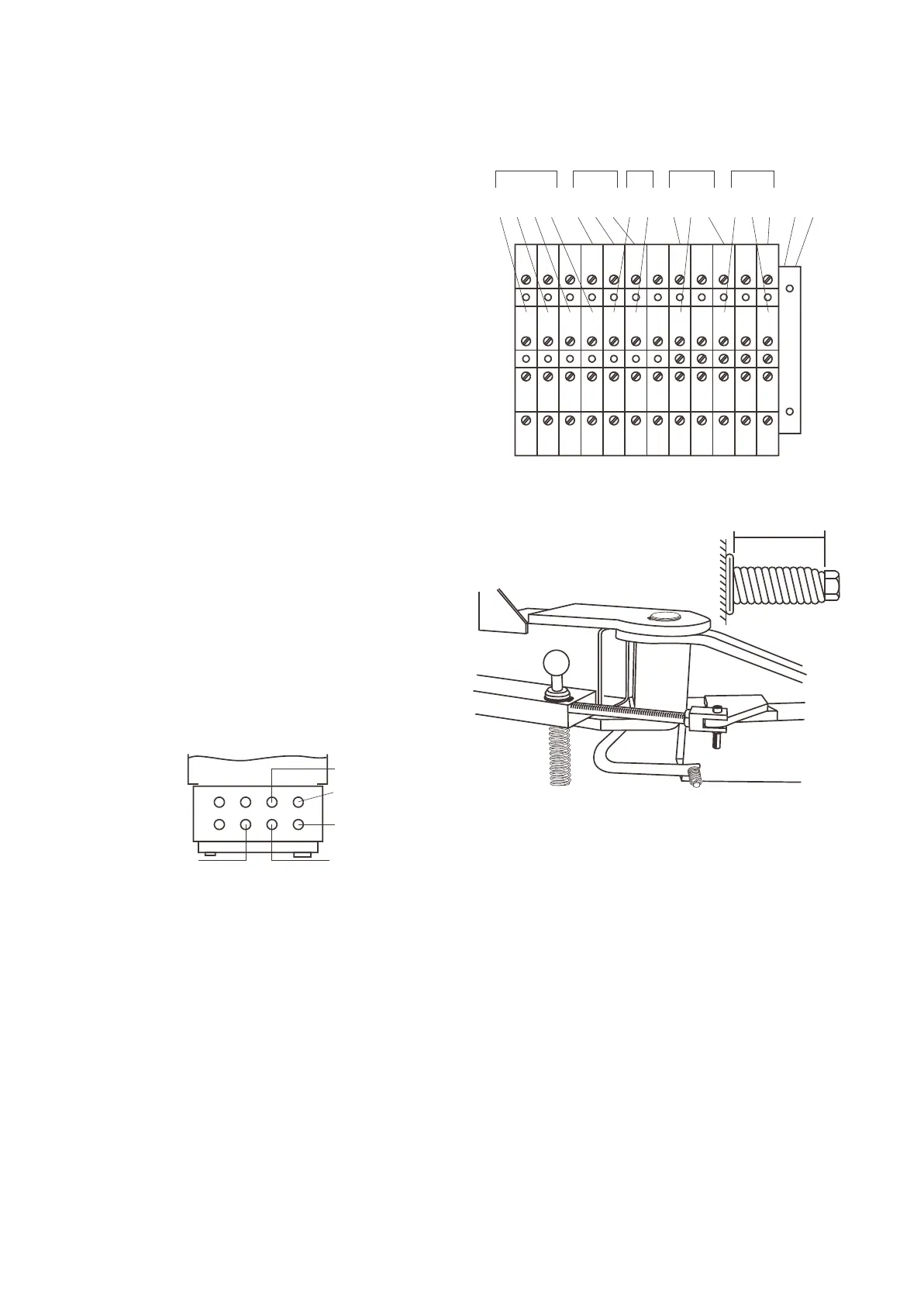

FIG.2

White

Brown

Blue

Black

Black

Brown

Blue

Brown

Blue

Black

Brown

Blue

Brown

Blue

Black

Green / Yellow - Slave Motor

Green / Yellow - Power Supply

Power Supply

Slave Motor

Drive Upright

Limit Switch

Slave Top

Limit Switch

Slave

Proximity

Switch

U W UV V W 9 10 11 12 13 14

L1 L2 L3 N 1 2 3 4 5 6 7 8

Earth

FIG.3

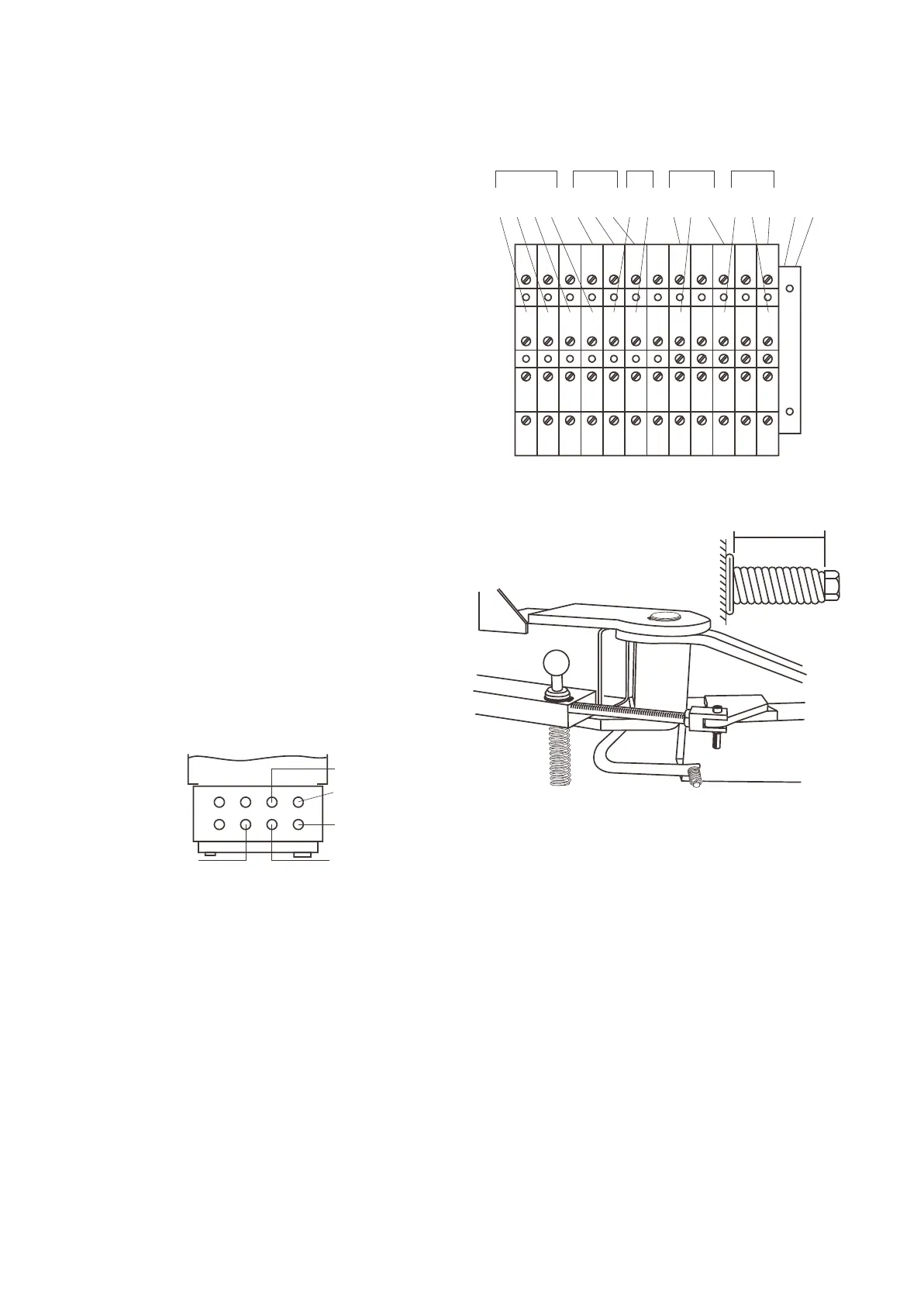

FIG.4

46 - 47 mm

10.Drill and fit eight hold-down bolts. The bolts must be

16 mm thread diameter and fitted in accordance with

the manufacturer’s instructions:

Approved expanding-type masonry anchors -

Ramset Trubolt T16125 and Hilti HSA stud anchor

M16 x 140/25.

Note: The bottom edge of the expansion sleeve on

the masonry anchor must be a minimum of 75 mm

deep in the concrete when tightened. If the base

has been shimmed up a large amount, longer

anchors will be required to ensure this depth is

reached. Tighten the anchor nut to 85NM (63 ft lbs)

If this torque cannot be reached, the connection is

not strong enough and must be redone.

Some authorities may not approve expanding type

masonry anchors. Approved adhesive masonry

anchors: Ramset Chemset capsule CHEM16 and

stud bolt M16190 and Hilti adhesive cartridge

HEAM16 x125 and anchor rod HASM16 X 190.

Tighten the anchor nut to 74 NM (55 ft lbs) after the

adhesive has cured. If this torque cannot be

reached, the connection is not strong enough and

must be redone.

Note: These fasteners require a minimum

concrete thickness and hole depth of 125 mm.

11.Add shims under the base frame, at the back of the

columns, as per Fig. 1, until there is only a small

gap. Measure the size of the gap with feeler

gauges. Loosen the 8 hold-down bolts. At the back

of the column, add extra shims to fill up the

measured gap and raise the height an extra 1.4 to

2.0mm. Eg for 0.6mm gap, add between 2.0 and

2.6mm of shims. Retighten and retorque all the

hold-down bolts.

12.Feed the wiring from the slave column through the

overhead crossbeam and uprights and into the

control box on the drive column as per Fig. 2.

Tighten the cable glands to seal the control box.

Connect the wiring to the numbered terminal strip in

the control box as per Fig. 3.

13.Apply a smear of grease in the lifting arm pivot holes

and the carriage pivot holes. Fit the lifting arms to

the carriages. Fit the pivot pins and retain with a

circlip top and bottom as per Fig. 4. Check the

circlips are fully in their grooves.

14.Fit the footguards to the lifting arms as per Fig.4

and tighten the bolts until the spring is compressed

to 46 to 47mm long.

15.Fit the tool trays to 2 of the lifting arms with the

M6 x 16mm long screws and the 19mm diameter

x 2mm thick flat washers. Tighten the screws up

snug tight only (do not over tighten as this will

distort the tray). Check all the arms slide in and

out freely.

16.Place a lifting pad in the hexagonal hole in each

lifting arm.

17.Fit the armlock devices to the carriages and arms

as per Fig. 4. Check that the circlips are fully in

their grooves and the Nyloc nut is tightened up

fully on the M8 x 55mm long cap screw. Lift up

on each black knob and check each arm moves

freely through the full arc. Release the knob and

check the arm is locked.

Page 5

(Neutral)

Loading...

Loading...