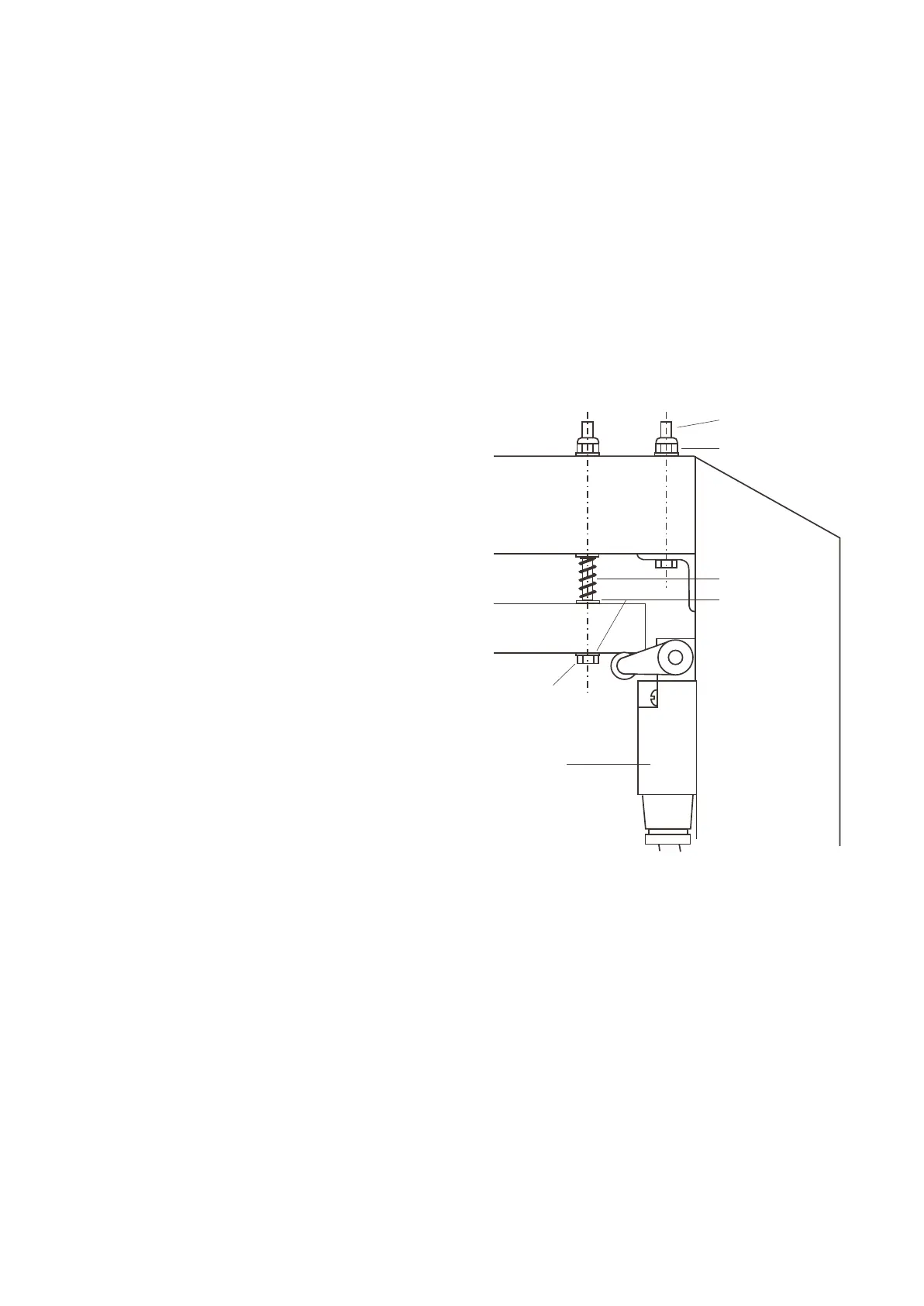

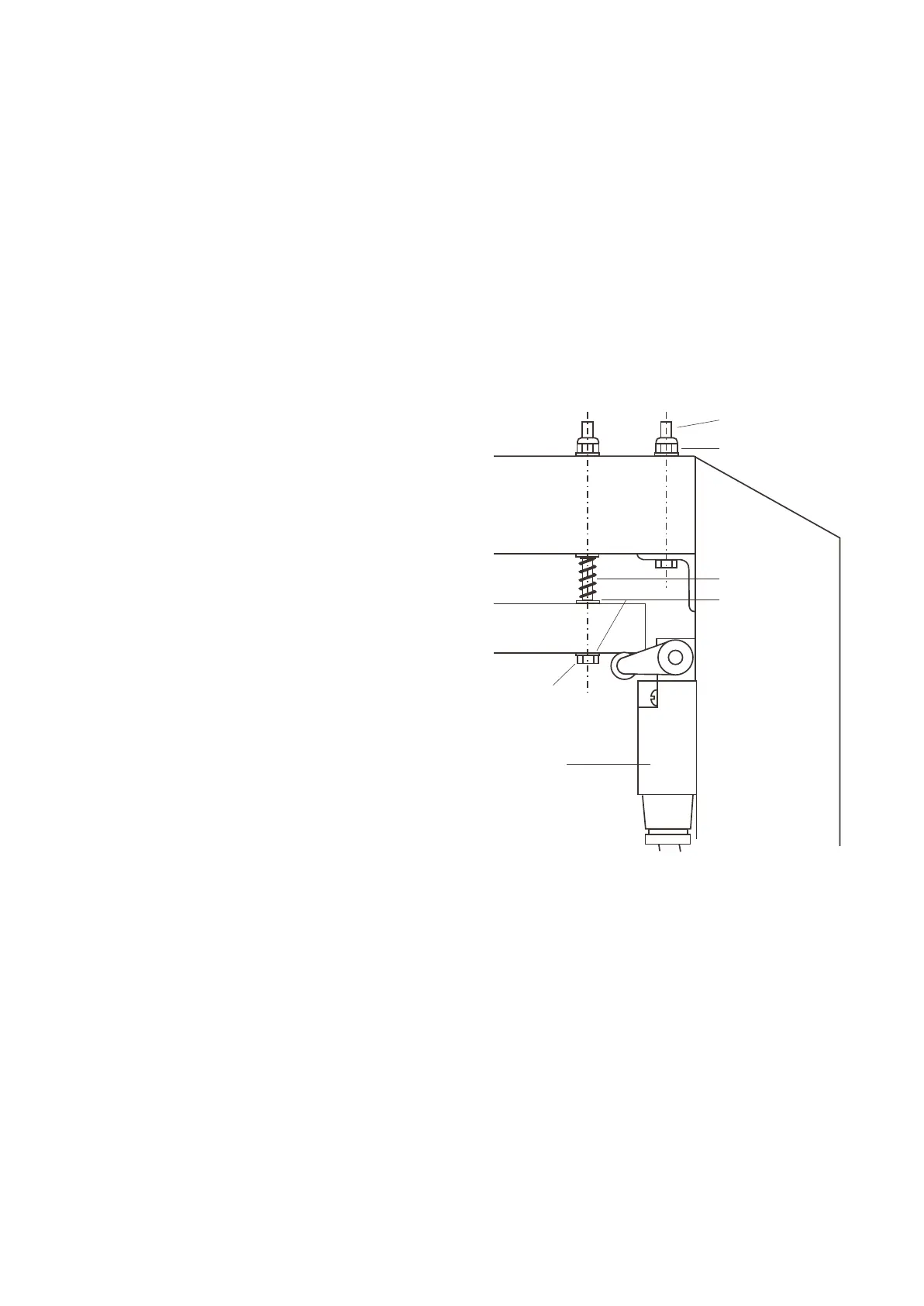

FIG.5

M6 x 65L Bolt

M6 Nyloc Nut

Cross Beam

25mm

Gap

M6 x 120L Bolt

Upright

V18944 Spring

Rubber

Washer

4 off

Limit Switch

18. Connect the power supply from the mains isolator

switch (adjacent to the hoist), to the control box on

the drive column. Use 4-core plus earth, 7 strand,

2

2.5mm copper cable. Fit the cable through the

cable gland as shown in Fig. 2 and tighten the gland

to seal the control box. Connect the wires as per

Fig. 3.

Note: This must be done by a qualified electrician.

19. Switch on the power to the hoist. Turn the isolating

switch to the vertical “on” position and wait until the

warning light comes on. Press the up button. The

hoist should go up. If it goes down, stop

immediately and turn off the mains isolator. Swap

two of the power supply wires at the terminal strip in

the control box. Switch the power back on. Check

the hoist goes up when the up button is pressed.

20. Drive the hoist fully up to check operation of the top

limit switches. Drive the hoist fully down to check

the operation of the bottom limit switches. Swing

the four lifting arms in and out with the lifting pads

screwed fully down. If the arms hit the floor in any

position, adjust the arms on the bottom limit

switches so the lifting arms clear.

Manually wind the hoist up by rotating the screw

pulley to check the carriage is still supported by the

lifting nut, not sitting on the bottom of the column.

Adjust the bottom limit switches so the lifting nuts

are still carrying the carriage when the hoist is

driven down fully.

21. Fit the covers over the bottom limit switches using

the M6 x 10 mm long socket head cap screws. Fit

the motor covers over the vee belts and secure with

the M4 x 10 mm long screws and large flat washers.

Fit the black plastic caps over the M12 nuts on the

back of each column.

22. Climb up a ladder and adjust the overhead collision

trip bar limit switch so that it just clicks on when the

trip bar is lifted then lowered slowly. For coarse

adjustment move the switch arm on its splined

shaft. For fine adjustment move the whole switch

up or down. Test the operation of the trip bar by

lifting up the trip bar at mid-span while driving the

hoist up. The hoist must stop! Release the trip bar.

The hoist must drive up.

23. Drive the hoist up 1 m clear of the floor. Fit a funnel

through the hole in the front blind in the drive

column. Pour in half a litre of the recommended

extreme pressure oil (supplied). Pour the other

half into the slave column.

Note: 1/2 litre of oil will half-fill the oil reservoir in

each column. Do not have the reservoirs more than

half full as the excess oil will be quickly lost.

24. Drive the hoist up and down four or five times to

lubricate the lifting screws.

25. Fit the heaviest available vehicle (maximum 3

tonnes) on the hoist and drive the hoist up and

down two or three times to test the operation of the

top and bottom limit switches and that it runs

smoothly and quietly. Stop at mid-height and check

it drives up again.

26. Demonstrate how the hoist operates to the owners

and operators. Give them this instruction manual

and ask them to read it and keep it for future

reference.

Page 6

Loading...

Loading...