Figure 2-3

7. Move the exhaust push tube to one side; rotate the

exhaust rocker lever to permit removal of Cummins

crosshead.

8. Install the new TecBrake crosshead. Note that it

comes with a new crosshead adjusting screw and nut.

Lubricate the crosshead and guide with oil before

installation. Make sure the crosshead adjusting screw is

on the exhaust manifold side of the engine.

9. Adjust the crosshead by holding it down against the

valve stem nearest the push tube, then turn in the

adjusting screw until it touches the valve stem.

10. Hold the adjusting screw in place and tighten the

locknut to 25 lbft (35N*m). Repeat operation for all

crossheads

6. Remove the rocker arm adjusting screws from the

exhaust rocker levers. Retain the Cummins locknuts and

screws.

Figure 2-4

11. Remove the injector adjusting screws from injector

rocker arm. Install the TecBrake injector adjusting screws

(hex head) furnished in kit. Reuse the Cummins

adjusting screw lock nuts.

CAUTION

The injector adjusting screw used in the TecBrake

Model T430A has a 5/8" hex head and height of 2".

Earlier model engine brakes used either a 5/8" or 7/

16" hex head and were 2.2" in height. These screws

are not interchangeable. Use of the wrong screw will

result in damage to the engine and brake.

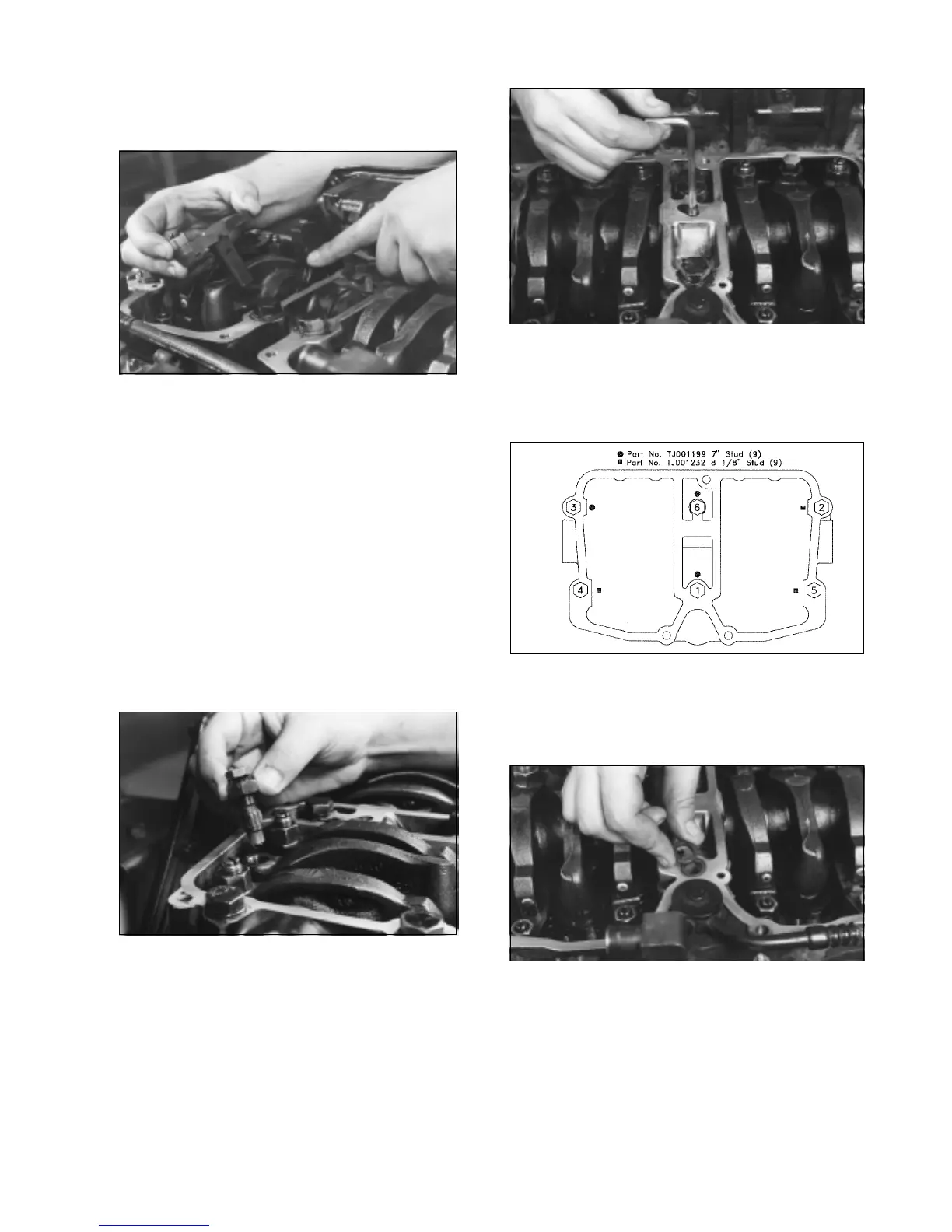

Figure 2-5

12. Remove the Cummins solid rocker shaft locking screws

from the cylinder heads and replace them with the hollow

set screws supplied in kit. Be sure screw is below flat surface

of the rocker housing when installed.

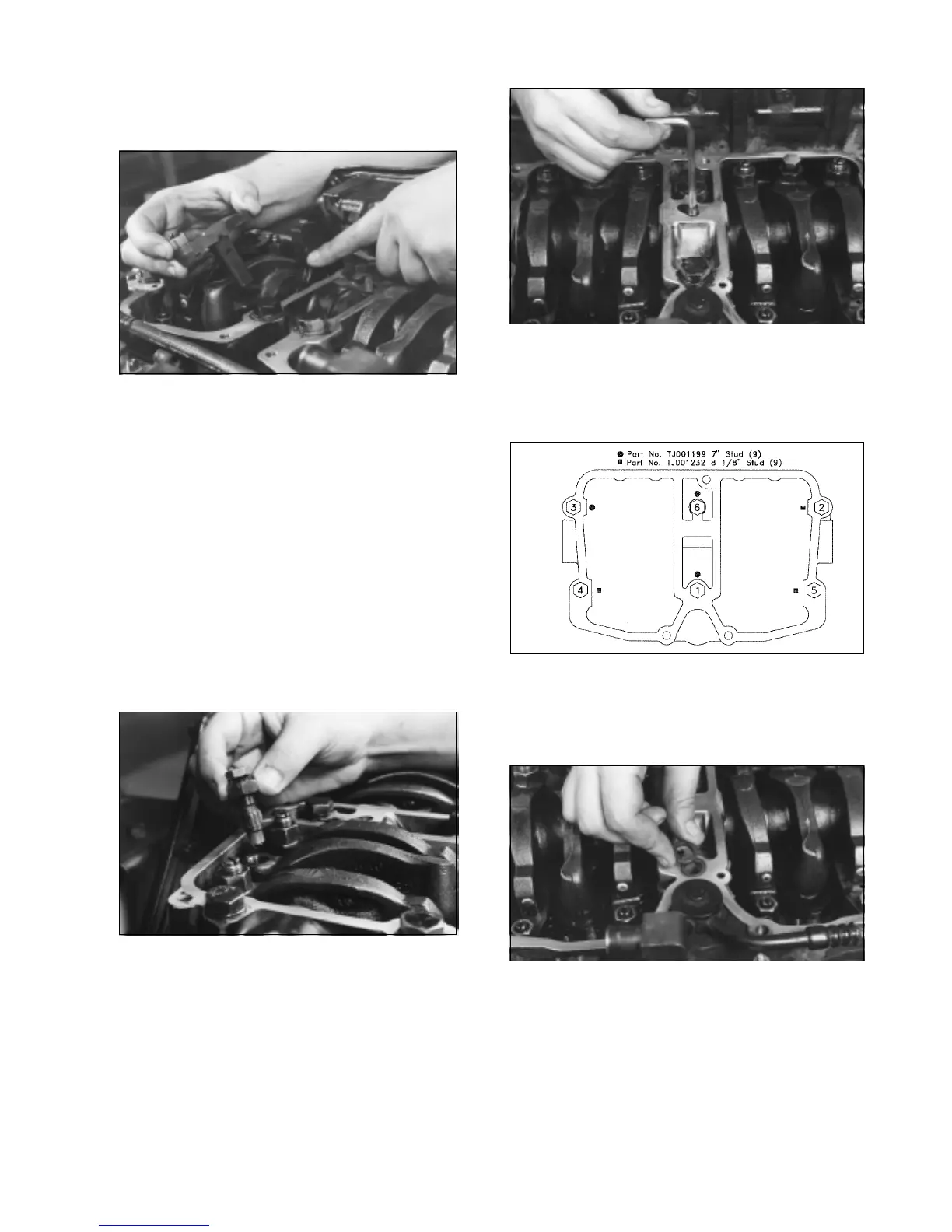

Figure 2-6

13.Remove three capscrews from each rocker housing in

positions1, 2, and 3 as indicated in Figure 2-6.

Do not

remove all six of the capscrews at the same time, as

this will permit the housing and gasket to move.

Figure 2-7

14. Install the special bearing washer into each rocker

housing capscrew bolt hole with the smaller diameter down.

NOTE: Bearing washers are not required in positions 2

and 5 if a fan brace is used.

15. Install studs supplied with kit in positions1, 2 & 3 as

indicated in Figure 2-6. Torque studs to 70 lbft (95 N*m).

16. Remove capscrews from positions 4, 5 & 6 as indicated

in Figure 2-6. Install new studs and torque to 70 lbft).

2

Loading...

Loading...