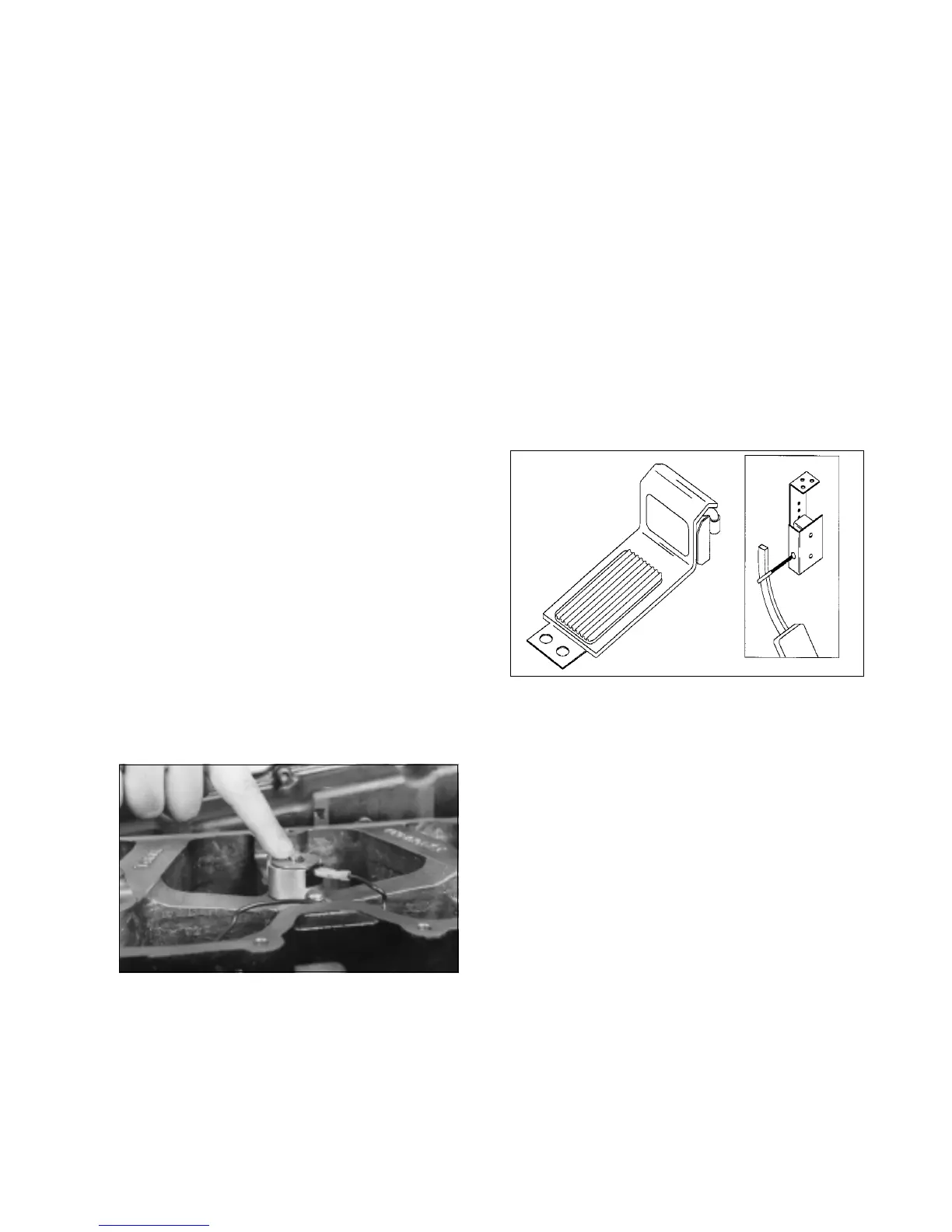

Figure 4-7

2. Bleed air from the engine brake housing. Accelerate

the engine to about 1800 RPM then release the throttle.

Quickly depress the solenoid as shown to cause the

brake to operate. This process should be repeated 5-6

times on each brake assembly in order to fill the housings

with lube oil. When all of the air has been removed the

brake should operate immediately when the solenoid is

depressed.

SECTION 5- ELECTRICAL SYSTEM INSTALLATION

Installation of the electrical system involves the mounting

of dash switches, a clutch switch, and a fuel pump switch.

An optional foot switch may be installed in place of the

clutch switch. Wiring harnesses are provided in the kit to

complete the installation. Refer to the wiring diagram Figure

5-8.

Dash Switches

Dash switches should be installed in dash where they are

visible and convenient to operate.

1. Drill holes in dash to accommodate switches and install

switches with proper name plates.

Clutch Switch

It is recommended that the clutch switch be mounted inside

the vehicle cab to protect it from road contamination.

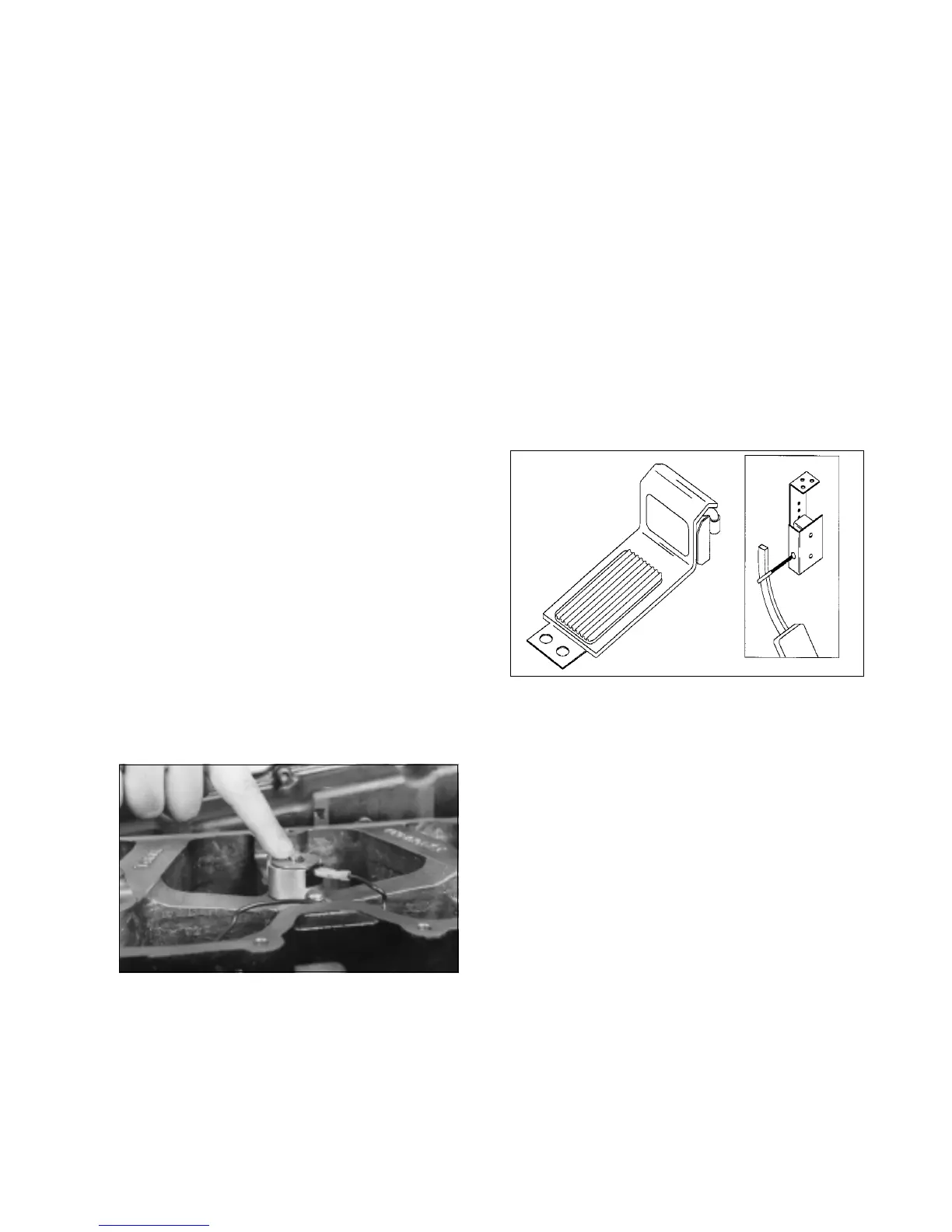

Figure 5-1

1. Mount the clutch switch in a convenient location near

the clutch pedal so that movement of the clutch pedal will

contact the clutch switch actuator arm. See Figure 5-1.

2. Adjust the clutch switch so that the actuator arm is

deflected from 1" to 1.5" (25 mm to 38 mm) when the clutch

is in the up (clutch engaged) position.

3. Check the switch by depressing the clutch. The switch

should "click" to an open electrical position as soon as the

free play in the clutch is taken up. When the clutch is

released, the switch should "click" to a closed electrical

position.

Optional Foot Switch

An optional foot switch may be used in place of the clutch

switch. The foot switch should be mounted on the cab floor

to the left of the clutch pedal and should be located so that

it can be conveniently operated with the drivers left foot.

Slave Piston Adjustment

Adjustment of the slave piston adjusting screw is critical.

Proper adjustment is necessary in order to provide peak

braking efficiency without over stressing the engine.

Slave piston adjusting screw adjustment must be

made with the engine stopped and engine

temperature stabilized below 140 ºF

.

1. Set engine brake valve lash using the adjusting

screw located above each slave piston. The engine

crankshaft must be rotated to allow the exhaust valve to

be fully closed prior to making adjustment on each

cylinder.

2. Back out the adjusting screw on each cylinder to be

adjusted. Using a 0.018" feeler gauge between the slave

piston and the exhaust crosshead, turn in the slave piston

adjusting screw until a slight drag is felt on the gauge.

3. Tighten the adjusting screw lock nut to 25 lbft (35

N*m) torque. Rotate the crankshaft, adjusting each

adjusting screw in firing order sequence.

Operational Check

Installation of the brake housings is now complete.

Functioning of the brakes should be checked before

proceeding further.

1. Start the engine and let it idle for a short time.

CAUTION

Wear eye protection. When engine is running with

valve covers removed, oil splashing will occur. Take

precautions to prevent oil contaminating engine and

engine compartment.

5

Loading...

Loading...