IST-2137.EC03.01/E Istruzione / User’s Manual / Manuel d’utilisation Pag. 11/20

TECNOCONTROL S.r.l. - Via Miglioli, 47 20090 SEGRATE (MI) Tel. +39 02 26922890 - Fax +39 02 2133734

paints. However, in case of products containing substances in great quantity, these could interfere with the Sensor

and cause false alarms. We recommend ventilating the room when products like these are used. Alcohols, Hydro-

gen and volatile organic solvents in great quantity cause false alarms, and then the cell needs one or more hours in

clean air to recover the normal sensitivity conditions.

TEST and CALIBRATION

PAY ATTENTION: This procedure has to be made with extreme attention and by authorized and trained people;

because starting this procedure it will increase mA output causing the activation of connected alarm devices.

Operation Check, Zero Adjust, and Calibration: are different code protected functions. To access these func-

tions is necessary to insert the relevant “Code" through the keys F1s and F2. To have the key pressure recog-

nized, hold pressing it for around a second (until the green Led doesn't switch off for a moment). Then the next key can be

pressed. In case of error all it takes is waiting around 10 seconds and the sequence is automatically erased.

The Calibration Check is a function code free.

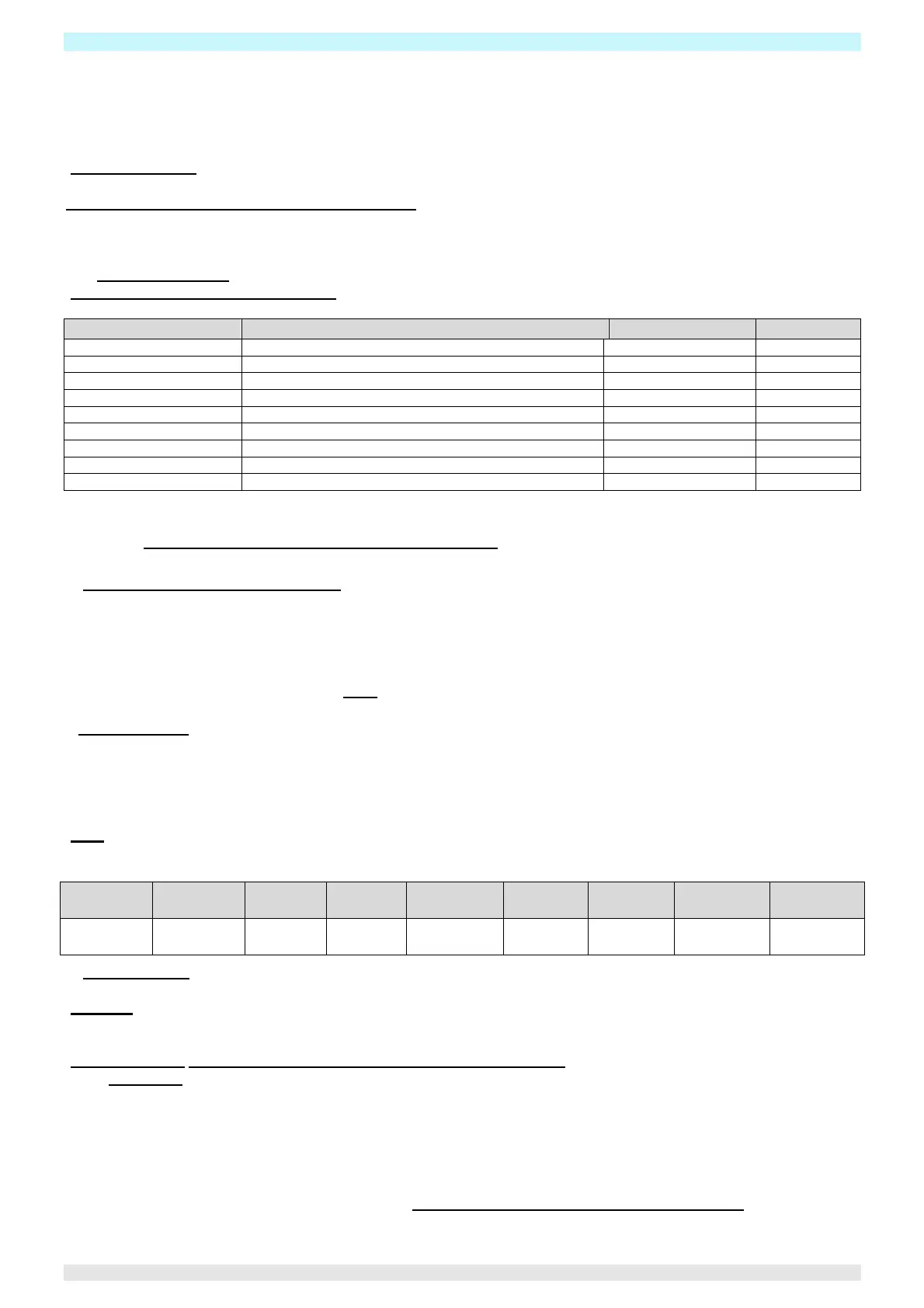

Calibration Kit, Sample Gas Bottles (for Calibration Check and Calibration) the mixture to be used depending on the

model installed is shown in the table below:

Sample gas bottle

Our Code KIT Code

100 ppm Ammonia (NH

) in Nitrogen Available on request TC014

300 ppm Carbon monoxide (CO) in Nitrogen BO210 TC011/TC014

10 ppm Sulphur dioxide (SO

) in Nitrogen Available on request TC014

50 ppm Hydrogen sulphide (H

S) in Nitrogen Available on request TC014

10 ppm Hydrogen cyanide (HCN) in Nitrogen Available on request TC014

100 ppm Nitric oxide (NO) in Nitrogen Available on request TC014

30ppm Nitrogen dioxide (NO

) in air Available on request TC014

10ppm Hydrogen cloride (HCL) in Nitrogen Available on request TC014

10ppm Nitrogen dioxide (NO

) in air Available on request TC014

It is possible to use either the disposable cylinders with adjust valve or the high pressure ones with reduction

gear. Some cylinders have a fixed flow reducers, make the necessary value in Table, column 3, page 11. Is also nec-

essary the Tecnocontrol calibration kit model TC014 (Inox). To ensure that the gas concentration reaches sen-

sor, use steel reduction gear and Teflon tubes or other compatible materials which do not disperse gas.

“INSTRUMENT OPERATION CHECK” (Check Code: F2, F2, F1, F1): this function allows to effect a functional test

of the detector. After having inserted the "Check Code", all Led are switched off and all the relays are deactivated.

Then they will switch on in sequence, the Led, from the yellow up to the 3° red. To the lighting of the various Led it

corresponds the activation of the relevant relays (relay "FAULT" with the yellow Led, relay "ALARM1" with the 1° red Led, relay

"ALARM2" with the 2° red Led, relay "ALARM3" with the 3° red Led). At the end all the Led will remain lighted for around 5

seconds, then the detector returns at the conditions of normal operation. It is advisable to perform this operation

every 12 months according to the use. Note: this function is not working if the 1° and/or the 2° and/or the 3° red

Led have already turned on.

“ZERO ADJUST” (Zero Code: F2, F1, F1, F2): this function is to adjust the Zero sensor and can be done in clean

air only (environment without the presence of toxic gas or other pollutants). Consider that the SE137E series have a sophisti-

cated follower of zero, that every hour will reset the sensor, if of course there is the presence of gas. If necessary,

perform this operation after installation or after changing the “Cartridge” or every 6-12 months depending on envi-

ronmental conditions. After entering the "Zero Code" as confirmation of the operation, there will be a flashing 1

st

red

Led and output becomes 4.0 mA.

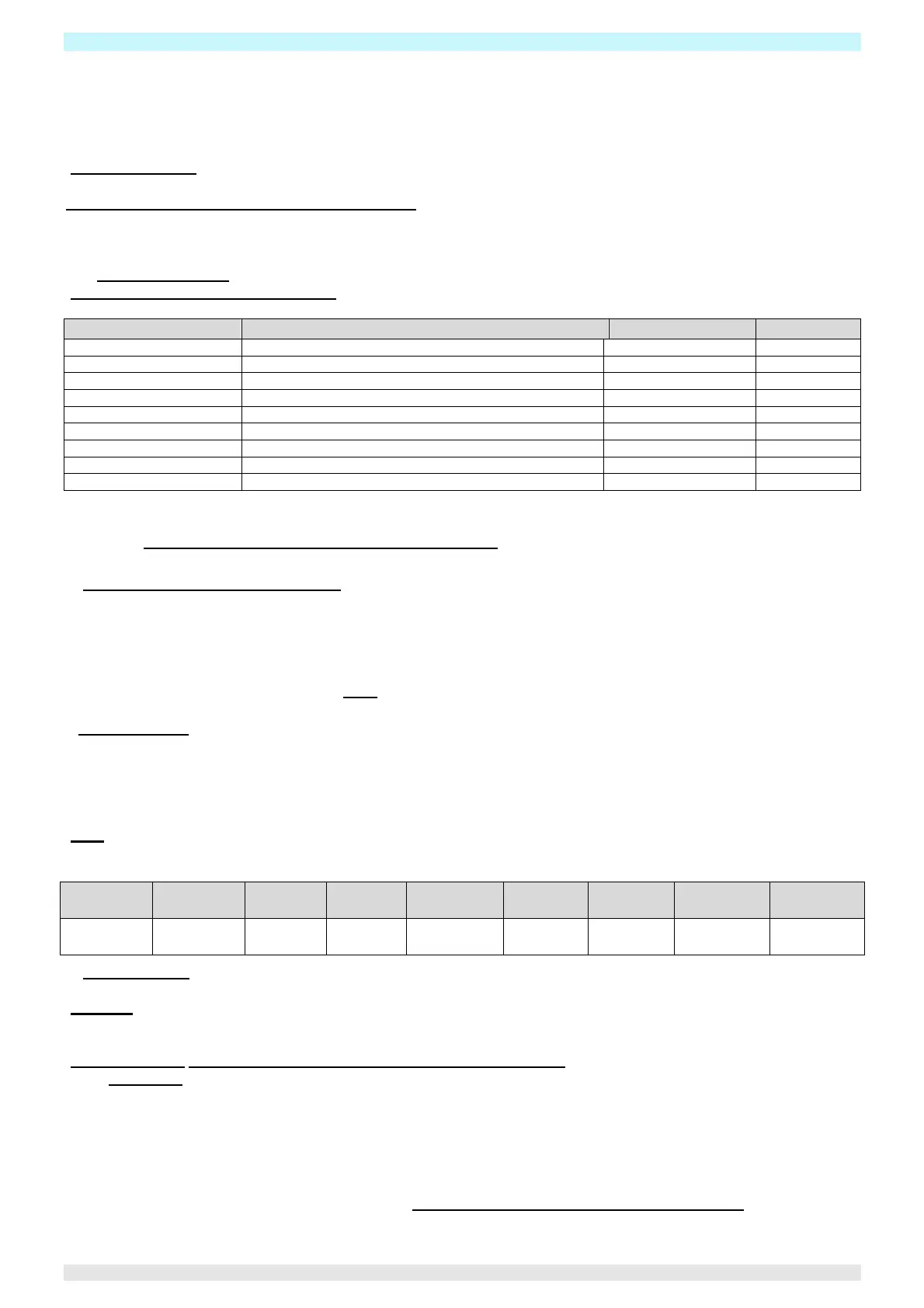

Note: This function is not working if mA output is higher than the value shown in the table below, depending on the

model, or if the 2

nd

and/or 3th red Led are already ON. In this case, please recalibrate the unit and/or replacing the

“Cartridge”. In case the 1

st

red Led will be already ON, only instead of flashing it will switch off for confirmation.

SE137EA-H

SE137EC-H

SE137ES SE137EH SE137EHCN SE137EN SE137EN2 SE137EHCL SE137ECL

15ppm NH

3

15ppm CO

3ppm SO

2

5ppm H

2

S

2,5ppm HCN

10ppm NO

5ppm NO

2

2,5ppm HCL

0,5ppm HCL

“CALIBRATION” (Calibration Code: F2, F2, F2, F1, F2, F1): this function allows completely recalibrate the sensor

using the gas mixture indicated above.

Warning: to guarantee that no errors of elaboration happen, the possibility exists that during the Calibration the yel-

low Led switch off every 8 seconds, in this case interrupt the procedure, switch off and switch on the instrument and

repeat the Calibration. If condition persists it will be necessary to send the detector to the supplier for the reparation.

Important note: during Calibration routine the mA output indicates 0mA.

The “Calibration” can be done in clean air only (environment without the presence of toxic or other polluting gas). With the

keys perform the “Calibration Code". Wait until the yellow and green Led switch on fix and the 1

st

red Led starts to

flash. Insert the TC011 on the sensor holder and adjust the influx of the gas the way that the flow meter reaches

the value indicates in table below in column 3, depending on the model (see also Fig.3).

Wait around 3-5 minutes, until the 3

rd

red Led lights (and while it is ON), press the key F2 and hold it pressed until

the 1

st

and 3

rd

red Led are switched off for at least 2 seconds (but if the 1

st

red Led continues to blink more than 5-6

minutes means that the gas flow is not constant or unsatisfactory, or the concentration is not as required, stop the

operation, turn off the instrument and recalibrate). Then, close the gas cylinder and remove TC011. At this point we

can have two possibilities:

Loading...

Loading...