Techno

Inc.

HTT03170704

4

Premium Class Setup Instructions

Phone: 516-328-3970 · Web: www.technocnc.com

Continue to next page …

TO REORDER VACUUM SUPPLIES:

Call Techno Today at: 516-328-3970

ITEM PART NUMBER

Rubber Plugs H91X30-PL006-001

Foam Rubber Gasketing HX4892-W0002

II. HOW TO USE THE VACUUM TABLE (CONT.)

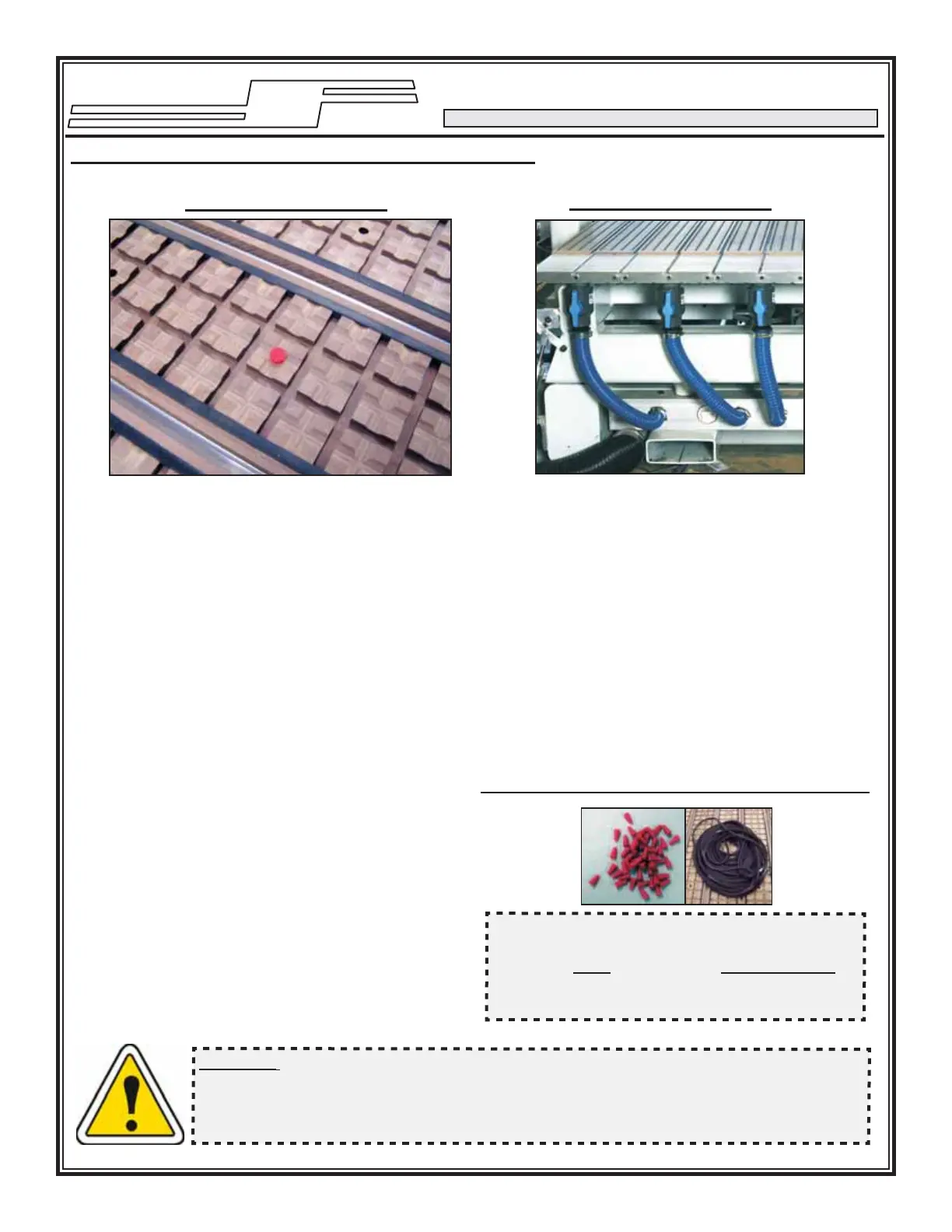

Vacuum Hold-Down - 1

The Techno Vacuum Table is very effective in

“holding down” parts to be routed. For this method

to work and work well, simple procedures need

to be followed. First, you need to defi ne the

area where your workpiece will be positioned on

the vacuum table. Second, using the red rubber

plugs, you need to plug-up and close-off all of the

area outside your defi ned work area. Fill in ALL

the vacuum grid holes outside your defi ned work

area with the plugs and leave the holes within your

work area open. Next, use the black foam rubber

gasketing to section/wall-off your work area. The

idea is to create an area of concentrated vacuum,

which will generate the greatest amount of vacuum

“hold-down.”

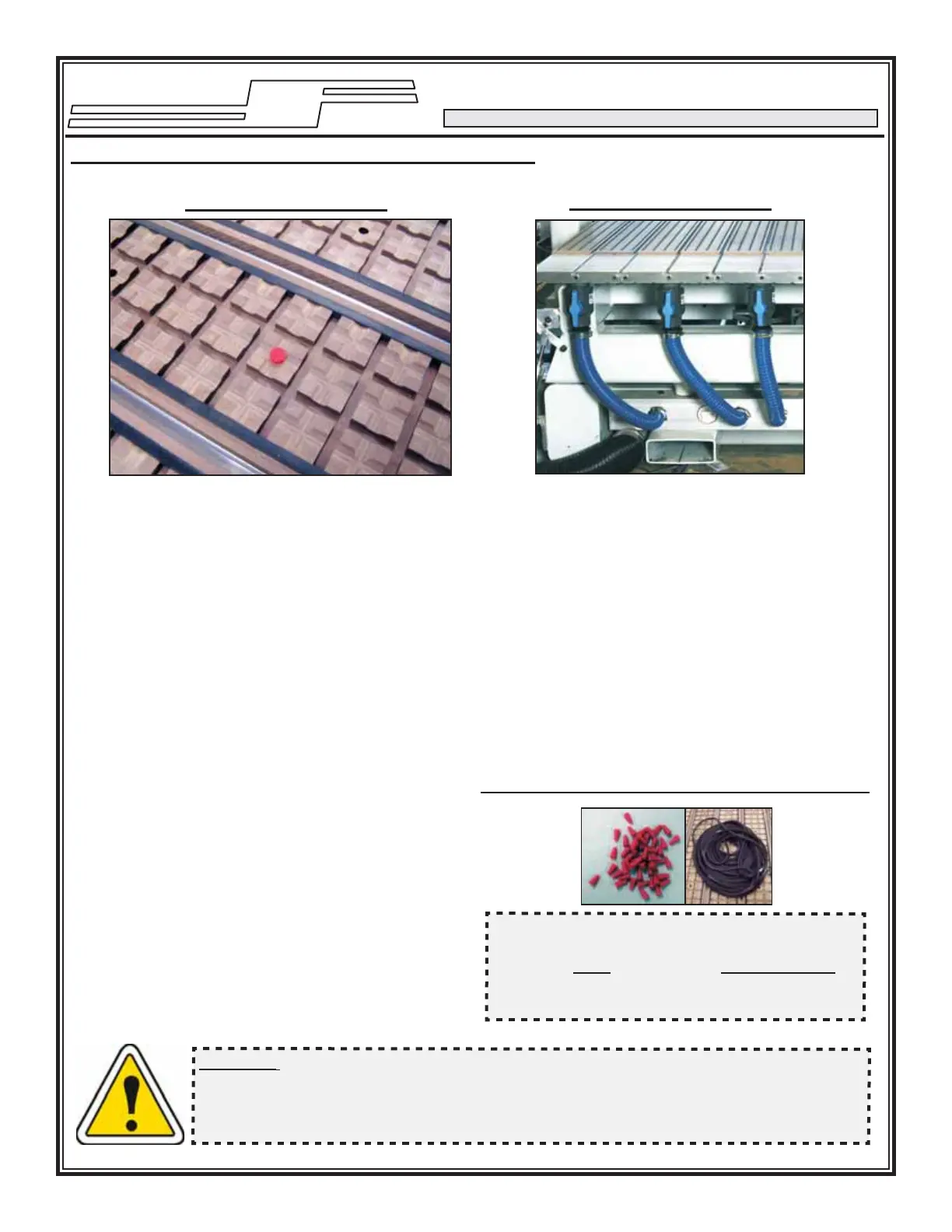

Vacuum Hold-Down - 2

After you have defi ned your workpiece

area and closed off all the vacuum

outside of that area, there is another

option to greater your vacuum: the

vacuum control valves. Each valve

controls the fl ow of vacuum to two rows

of extrusions. Turn ON (valve vertical)

the valves that pertain to your work area

and turn OFF (valve horizontal) the ones

outside of that area. This will concentrate

all the vacuum “hold-down” capacity to

your defi ned work area.

NOTE: You do not need to plug vacuum

holes in a section that has the valve

turned OFF.

WARNING: Proper care should be taken to make sure that objects held down with the vacuum table

are secure. There is a danger that objects held down with the vacuum can become loose and could be

thrown by the action of the cutting tool. Proper safety precautions against fl ying debris must be taken.

Safety glasses must be worn when the vacuum table is being used.

Important Gasketing Installation Notes:

1) DO NOT STRETCH the gasket material while

inserting it into the gasket slots. This will

produce tears in the gasket material which

causes leaks leading to the loss of vacuum

and unsecure pieces fl ying off of the vacuum

table.

2) When joining two separate pieces of gasket

material, make sure to push them together

so the two pieces forma tight seal.

Loading...

Loading...