80

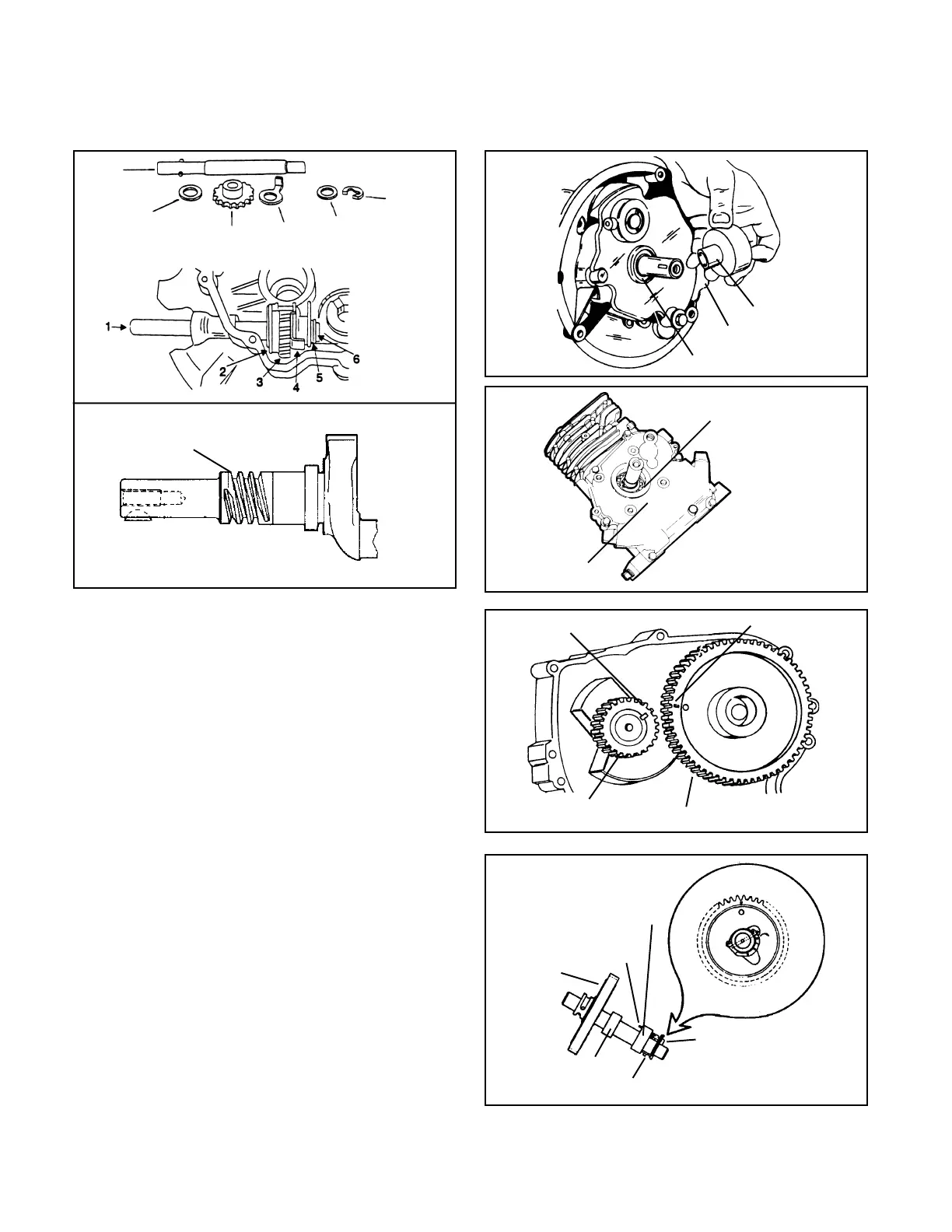

14. Remove the internal components. Align the timing

marks on all engines except VM70, 80, 100, HHM80,

HM70, 80, 100, TVM170, 195, 220 to relieve valve lifter

pressure. On these engines it is necessary to rotate

the camshaft clockwise three (3) teeth past the aligned

position to allow the compression release mechanism

to clear the exhaust valve lifter and to allow the

camshaft to be removed (diag. 19 & 20).

TIMING MARK

19

20

OIL SLEEVE TOOL

MOUNTING FLANGE

OIL SEAL

SNAP RING

OIL SEAL REMOVED

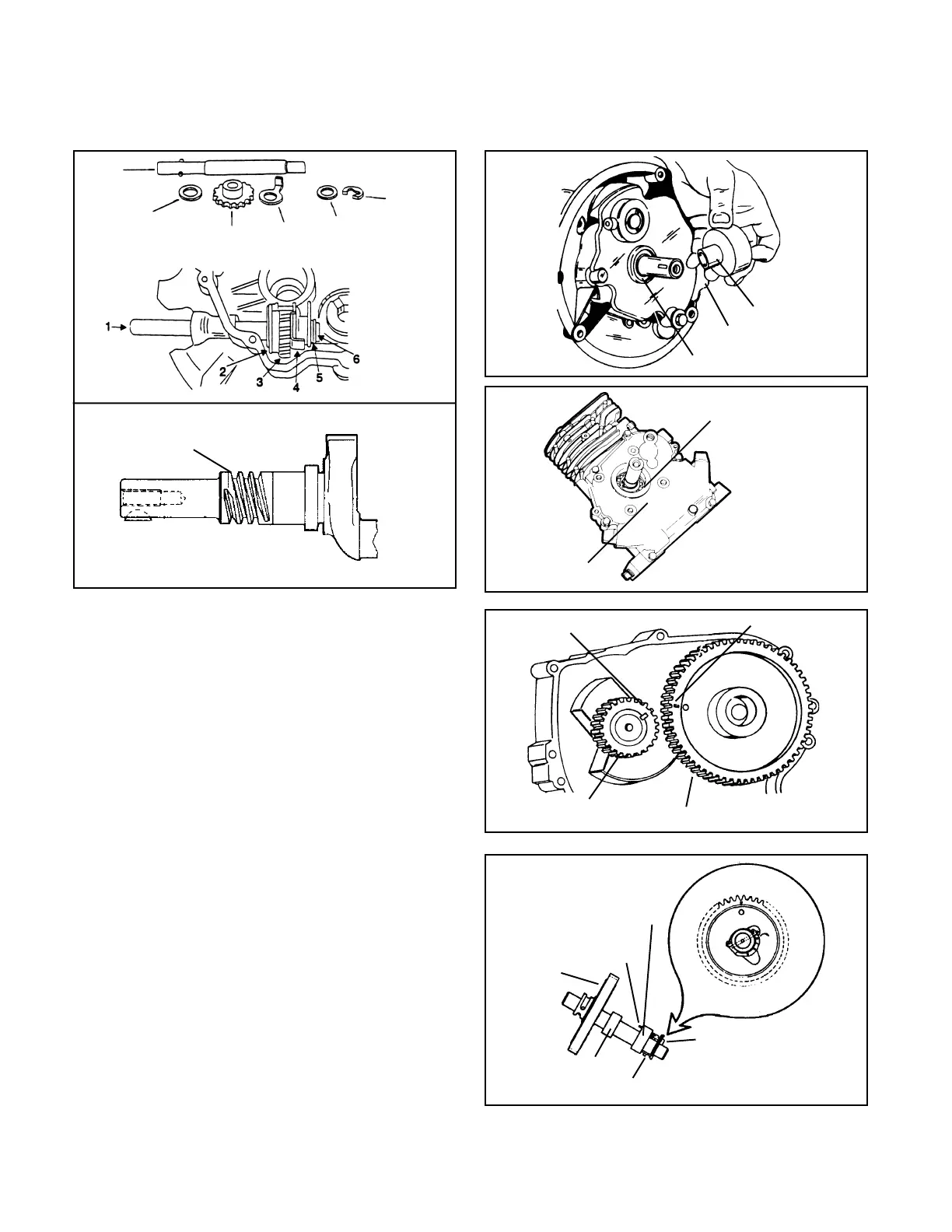

13. Remove the cylinder cover or mounting flange using a seal protector positioned in the seal to prevent seal damage.

The crankshaft must be free of rust or scale to slide the cover off the crankshaft. H30-HS50 horizontal crankshaft

engines with ball bearings on the crankshaft require the oil seal and the snap ring to be removed prior to the cylinder

cover removal. On engines equipped with 8 1/2:1 gear reduction, turn the crankshaft to roll the reduction shaft gear off

the crankshaft worm gear when removing the cylinder cover (diag. 15, 16, 17, 18).

WORM GEAR

15

17

16

18

BEVELED TOOTH

CAMSHAFT GEAR

CRANKSHAFT

GEAR

15. Remove the lifters, rod cap, and balance shaft or gears

if applicable.

16. Before removing the piston, remove any carbon from

the top of the cylinder bore to prevent ring breakage.

Push the piston out the top of the cylinder bore.

17. Remove the valves by using a valve spring compressor

to compress the valve spring and rotate the valve spring

retainer to allow the valve stem to pass through. Lift

the valves out of the cylinder block. Remove the spring

assemblies being careful to note the differences, the

original placement of the springs and the presence of

seals. Reinstall the spring assemblies on the same

valve in the reverse order as they are removed.

EXHAUST CAM

ROLL PIN

CAM GEAR

SPRING

INTAKE CAM

PLUNGER (COMPRESSION RELIEF PIN)

1. PTO

Shaft

2. Thin

Washer

3. Gear

4. Tang

Washer

5. Thick

Washer

6. Retainer

Loading...

Loading...